Search

Login

Recommended

What is roofing mastic, the rules for applying roofing mastic

A wide range of roofing materials, presented on the construction market, dictates the need for a clear presentation of the advantages and disadvantages of each of them. This article is a detailed guide that will discuss the use of mastic as the main waterproofing tool, as well as the principles of classification of mastics.

Content

- Historical reference

- Roofing mastic and its scope video

- Classification of mastics by method of application

- The role of proper mastic application in the wear resistance of the roof

- Mastic roofing TechnoNICOL

Historical reference

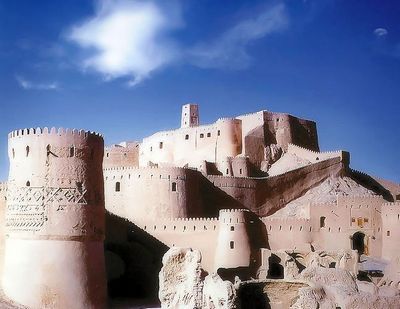

Waterproofing, the technological solution of which is aimed at the use of bitumen derivatives, existed in the Ancient World. Many Egyptian sights and structures found between the Euphrates and the Tigris were built using materials that included bitumen in their structural composition. Reservoirs and storages for grain, palaces and temples, the slabs of walls and floors of which were fastened together with bituminous resins, the tunnel, the construction of which is connected with the first millennium BC, all this is constructed using bitumen.

Since then, the entire construction industry has evolved through various stages of its existence. Along with this, the use of mastics as leading waterproofing tools has also developed.

The 1960s were marked by the modification of mastic with substances with a polymer structure, which improved its mechano-physical characteristics and increased the expected service life. At present, mastic is recognized as the ancestor of absolutely all rolled materials intended for roofing, the technological principle of which is to apply mastic to a knowingly prepared base in the conditions of a conveyor.

Roofing mastic and its scope

What is roofing mastic? The scope indicates that this is a material that is famous for its versatility, which determines its relevance, both in roofing and in other branches of the construction business.

The installation of a roofing carpet, one of the stages of which is represented by waterproofing, is the main direction of the use of mastic, that is, all situations associated with the need to protect surfaces or rooms from water will not do without the use of mastic.

An analysis of the composition of roofing mastic shows that bitumen prevails in its structure. But in matters related to the roof, the most stringent requirements are placed on the mastic, which dictates the need for more complex technological mechanisms for its manufacture. They consist in the addition of polymerizable substances. They help to achieve a certain level of elasticity and frost resistance of roofing mastic, intended for waterproofing.

Classification of mastics by method of application

When choosing mastic, you should know that differences in the method of application of the specified building material determine the division of mastics into cold and hot.

Such a division indicates that the use of hot mastics is impossible without preliminary heating, while cold mastics do not feel the need for this procedure. But they also have their own specifics: depending on the prevailing structural component of cold mastics, a classification has been created that provides for their division into emulsion and solvent mastics. Each of them is characterized by advantages and negative aspects.

mastic roofing hot, the main characteristics

Mastic roofing is a hot material necessary for the installation of a roofing carpet, which is tested by time and the destructive effect of excess moisture. Using it, remember that the basic rule is preheating to 160-180 degrees.

After completing it, you can go to the next stage, which involves applying mastic to a deliberately primed surface. After waiting for the temperature to drop, you will see that cooling helps to change the structure of the mastic, and it takes the form of a refractory coating of the desired elasticity and strength.

Determining the main characteristics of mastic of bituminous roofing hot, it is necessary to mention the absence of a tendency to shrink when hardening, non-porous structure, effective use at temperatures below zero, as well as a lower price. All of the above characteristics can be considered pluses of this type of mastic. But we must not forget about the minuses. These include a high risk of fires and burns, energy consumption during processing and inconvenience during the application of mastic.

cold roofing mastic

The desire of manufacturers to simplify the technological features of production contributed to the entry into widespread consumption of cold-type mastics. The features of its composition make it possible to distinguish mastics, the background component of which is a water base and mastics, the manufacturing technology of which involves the use of solvents. Their application is based on a change in the crystal lattice and the formation of a monolithic moisture-resistant layer that occurs after the evaporation of water or solvent. Experts advise giving preference to water-based mastics, the so-called bitumen emulsions, in view of their low toxicity and explosion safety.

The role of proper mastic application in the wear resistance of the roof

The wear resistance of the roof, the constructive solution of which provides protection against moisture through the use of bituminous roofing mastic, is correlated with the correctness of applying it to the base.

A high level of performance is also not possible without observing the technological rules for the preparation of the building mixture. In this matter, specialists are on the side of single-component mixtures, since they represent a ready-to-use substance and do not require specific cooking procedures.

mastic application methods

Uniform distribution of mastic on the base can be carried out by several methods. The most technologically advanced of these is the automated method, the concept of which is to use an air atomizer. It allows you to maintain at the proper level the uniformity of the application of moisture-resistant material even with a non-standard configuration and excessive slope of the roof.

Adherents of conservative methods will approve the distribution of mastic on the base by means of a roller or brush, the so-called manual method. The main disadvantage of this method is the difficulty in obtaining the required coating thickness, which is especially noticeable with significant irregularities.

Roof repair using mastic does not require the removal of obsolete coatings, except in cases associated with excessive use of roofing material.

Mastic roofing TechnoNICOL

The competence of the TechnoNICOL Corporation includes the development of compositions of mastics, the structure of which is dominated by bitumen, and the implementation of these ideas into practice. The products of their association will become a loyal assistant in the development of projects for waterproofing the roof of industrial and civil facilities, as well as in the repair of roofing carpets.

The structure of TehnoNikol roofing mastic is represented by a mixture, the components of which are bitumen with modification by polymerizing substances, crumbs of mineral origin and an organic solvent. The service life of structures, the design of which provides for the protection of waterproofing mastic TechnoNICOL, will delight you with positive developments in this area, due to the expansion of the operating temperature range.

Mastics, the production of which is associated with the name of this corporation, will become a quality basis for waterproofing structures that are actively in contact with a humid environment, and will also not be superfluous when designing a bitumen roof.