Search

Login

Recommended

Paving slabs, types of paving slabs, do-it-yourself paving slabs

There are many building materials that only specialists have known about for a couple of decades, and now it is difficult to imagine our garden plot without them. Some of them are the product of a complex technological and chemical process, the possibility of release of which appeared only thanks to new discoveries in materials science. But there are also quite simple products that could appear, but, unfortunately, did not appear in the arsenal of builders at the beginning of the last century. But now, when these materials have been tested and proved to be economical, they are catching up at a gigantic pace and have entered the life of almost every summer resident. This, in particular, is about paving slabs, an indispensable material in the equipment of the garden space. Let us dwell in more detail on the types, properties and characteristics of these products and tell you how to properly lay paving slabs on the site.

Content

- Paving slabs properties and characteristics

- Types of paving slabs

- Production of paving slabs video

- Laying paving slabs video

- Care for paving slabs

Paving slabs properties and characteristics

Paving slabs, or it is also called paving slabs, began to be actively used in countries where there was an acute shortage of stone to pave the roadway, and subsequently pavements. In our country, its use reached serious indicators in the 70-80s of the last century, but production was limited only to tiles of a rather large size, which often cracked and were short-lived in operation.

A real breakthrough in the use of paving slabs occurred from the moment of the beginning of its production with new pressing methods, which made it possible to reduce the size, and therefore increase the strength of the products. The main properties of modern concrete paving slabs are as follows:

- the tile withstands significant temperature extremes, which allows its use in areas with any, even the most severe climate

- the tile is highly environmentally friendly, as it is made of natural materials, without the use of chemical compounds, that is, it does not pollute the environment at all

- the tile does not melt in the sun, which makes it a more reliable material than asphalt

Technical and physical characteristics vary depending on the method of manufacturing the tiles and include the following parameters fixed by GOST.

Casting tiles using vibration effect:

- strength from 100 to 300 kg / sq.cm

- frost resistance class F200 (the figure shows the number of freeze-thaw cycles that the product can survive)

- water absorption up to 5% of volume

- the life of such tiles can be up to 10 years

With the production method by dry vibropressing, the characteristics are significantly improved and the service life is extended to 25 years:

- strength 300-400 kg / sq.cm

- frost resistance up to F300

- water absorption up to 0.5 volume

As you can see, vibropressed paving slabs practically do not absorb water, therefore it is very reliable when used in areas with high humidity.

Types of paving slabs

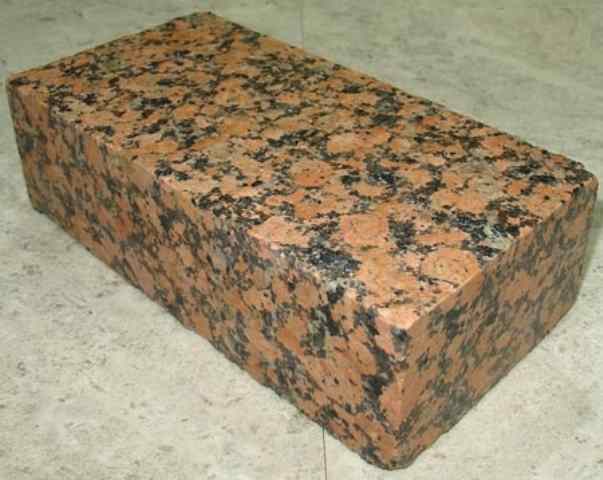

Paving slabs has several types, distinguished by the material from which it is made. The most common tiles made of concrete. She is also the cheapest type of product. More expensive types of clay are produced, which has some analogy with roof tiles. Also, various natural stones can be used as a material for production, for example, you can often see granite paving stones, incredibly strong, but, unfortunately, having a rather high cost.

Granite chips with the addition of special binders can also be used in the production of paving slabs, but these products have complex manufacturing techniques and require high professionalism in laying. Paving slabs have a large number of shapes and sizes, and also provides for the possibility of tinting, which greatly diversifies the products.

Production of paving slabs

Paving slabs are mainly manufactured in three ways. In this case, the mixture consists of the same components of concrete, water and filler.

Vibration casting. This method is pouring the mixture into a plastic or metal form for paving slabs, which is then placed on a vibrating table for paving slabs with a special device with a constantly vibrating surface. After tamping, the mixture forms are moved to the drying chamber or covered with a special dome. Drying temperature is maintained at around 38 degrees. Drying lasts 12 hours, after which the finished product is removed from the mold. This process is used in industrial production. But by casting it is quite possible to produce paving slabs at home in small quantities, with some change in technology (vibration is carried out manually and drying time at room temperature doubles). Watch the video, the whole process of making paving slabs with your own hands is very clearly demonstrated.

Vibrocompression. The concrete mixture is poured into a matrix (mold with numerous cells), which is mounted on a vibrating bed. After filling the matrix, a punch enters into it (a kind of piston similar in size to the matrix, but slightly smaller along the perimeter), which also vibrates continuously. Under pressure, the mixture in the mold is compacted. Upon reaching the required degree of compaction, the die with the punch is lifted and the finished product remains on the bed.

Hyperpression. Similar to the previous method, but without using the vibration effect. The hydraulic press creates strong pressure (from 150 to 250 kg / cm2), with which the mixture is compacted. This method has high productivity and is almost completely automated, which reduces the share of manual labor to a minimum, thereby reducing the cost and human factor, which, as you know, can adversely affect product quality.

Laying paving slabs

It’s quite possible to lay the paving slabs with your own hands, you just need to properly prepare a flat surface, stock up with sand for the pillow and provide a drain, for which the principle of transverse slope is used, that is, the track or platform, which is supposed to be laid, should be slightly inclined so that the water leaves into the soil on the side or a nearby water trough. The whole process of laying paving slabs is clearly demonstrated in the video.

Care for paving slabs

The durability of the paving slabs laid on the site is confirmed by the experience of its operation. But you can even extend the service life if you conduct elementary operations to periodically remove grass and other plants that have sprouted through the joints of blocks, as well as clean the surface of paths and platforms from dirt and possible organic waste that has fallen on the paving slabs. The most optimal cleaning option is cleaning with a water jet from a pump or high-pressure apparatus.