Search

Login

Waterproofing a flat roof, how to do waterproofing yourself

When laying a new roof or repairing an old one, many people ask themselves: Is it worth spending time and money on waterproofing a roof? It is impossible to neglect this event, because in the future it can lead to the destruction of the integrity of not only the roof, but also the room itself.

Due to its functional and design features, flat roof waterproofing differs from sloping roof waterproofing in the choice of materials and the technological process.

Content

- The role of roof waterproofing in the operation of the room

- Types of flat roofs and basic rules for their waterproofing

- Options for waterproofing and technology for applying them to a flat roof

- Do-it-yourself waterproofing the roof of the garage

The role of roof waterproofing in the operation of the room

Roof waterproofing is an important stage in the construction of a house, a garage and any other building. Work to ensure the protection of the premises from water penetration must be carried out directly during the construction of the structure, and not after a couple of years.

Waterproofing a flat roof performs specific functions:

- protects structures from the harmful effects of precipitation (rain, snow, hail);

- prevents leakage (the coating retains moisture on the surface even with significant temperature fluctuations);

- the walls of the structure wear out more slowly;

- protection of the room from the occurrence of dampness and the growth of bacteria, fungi.

Types of flat roofs and basic rules for their waterproofing

When choosing a method of waterproofing a flat roof, it is necessary to take into account the type of roof:

- The exploited can be used as a recreation area, a small garden, parking for cars, a swimming pool.

- Unexploited does not perform any additional functions and does not require regular maintenance (pressure on the roof surface is excluded).

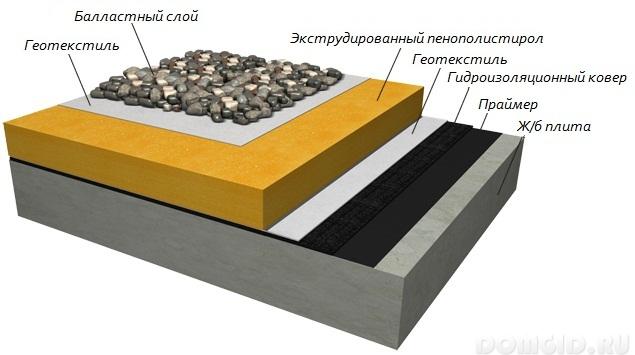

When equipping an exploited flat roof, a layer of waterproofing material is located under the insulation (extruded polystyrene foam).

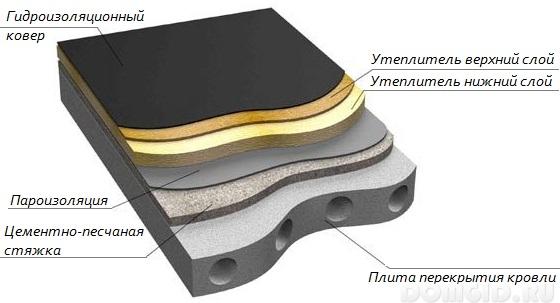

The non-operating roof consists of a base (base plate) and a heat-insulating material protected by a waterproofing carpet from the damaging effects of the environment.

The principle of waterproofing flooring is almost the same for both types of flat roofs. You can highlight the basic rules that must be considered when designing and installing waterproofing:

- the roof should be located at a slight angle, so that water flows freely through the drainage, and does not collect in the center;

- the waterproofing layer must be solid, homogeneous and not contain cracks or gaps;

- rooftop drainage should have high throughput;

- at the exit points of the communication structures (ventilation, chimney), it is desirable to raise the protective coating layer.

Under these conditions, it will be possible to obtain a durable and high-quality waterproofing of the roof.

Options for waterproofing and technology for applying them to a flat roof

roof waterproofing materials

The way to protect the roof from water penetration is determined by the choice of waterproofing material.

Today, the following protective coatings are common:

- polymer film membranes;

- waterproofing mastics (bituminous, acrylic, rubber, silicone);

- rolled and sheet materials (roofing material, brizol, fiberglass, glassine);

- painting materials (polymer and bitumen varnishes, emulsions, paints);

- sprayed materials (liquid rubber);

- penetrating impregnation (floor materials and penetrating into the porous structure of the roof surface).

polymer film membranes

The membrane is the latest waterproofing technology, which is based on laying a special film consisting of several layers (reinforced polyester inside and PVC on the outside). The average dimensions of the protective sheet are 60 m in length, and the width is up to 15 meters.

The service life of the membrane coating ranges from 25 to 50 years (depending on the type of film-membrane). The canvas can withstand temperature fluctuations (from -60 to +120 degrees Celsius).

Individual membrane strips are laid out on the roof surface with an overlap (about 5 cm). There are three ways to fasten a waterproofing sheet to the roof:

- fastens mechanically using brackets, screws, nails;

- ballast method (falling asleep with gravel or gravel; it is used more often on operated roofs);

- by gluing (at the junction in many membranes self-adhesive tape is provided).

Typically, waterproofing membranes are used on large surfaces, on a compact flat roof it is more cost-effective to use polymer mastic.

bulk roof with mastic

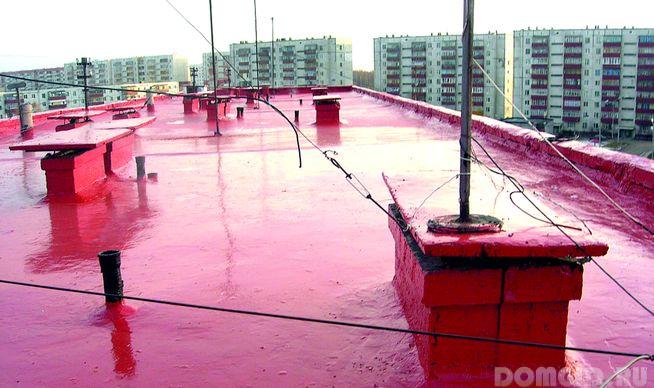

Liquid waterproofing of the roof is the application of mastic on a flat roof (with a minimum angle of inclination). Mastic can be applied with a roller or a paint brush in one or two layers.

By the method of application, hot and cold mastics are distinguished. Before use, mastic must be heated to a temperature of +160 degrees. Cold mastic needs to be warmed up to +70 degrees if at the time of waterproofing the outdoor temperature is below +5 degrees Celsius.

After solidification of the bitumen-polymer mastic, a durable rubber-like coating without seams is formed. The protective film does not melt at high ambient temperatures and is resistant to alkalis, acids, gasoline and oils.

The service life of the waterproofing coating is about 20 years. Mastic is perfect for waterproofing joints and inaccessible places on the roof.

the use of roll guided materials

One of the most economical and oldest ways to waterproof a roof. When working, the following can be used: roofing material, ecoflex, polyvinyl chloride, isoplates, hydroisol, isola, brizol.

Roll and sheet materials are overlapped by 10-15 cm. The surface is pre-cleaned, dried and processed with bitumen emulsion (primer layer).

Installation of such waterproofing is a rather laborious process. Laying can only be carried out at an air temperature of at least 10-15 degrees.

liquid rubber as the most effective roof waterproofing method

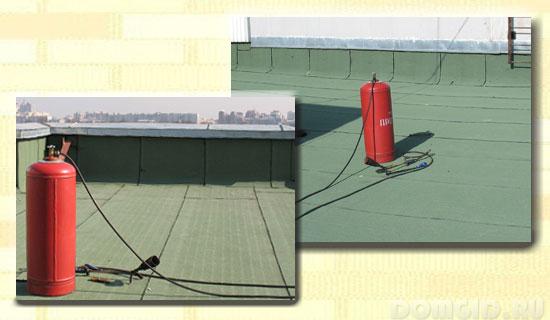

Waterproofing with liquid rubber provides reliable protection of the roof from moisture. On the roof surface, an integral, without a single seam, coating is formed. Liquid rubber is an excellent vapor barrier, which makes it possible to save on the purchase of additional materials.

Spraying liquid rubber the ability to waterproof a large surface area of \u200b\u200bthe roof in a short time. Hardening occurs during the day.

For applying liquid rubber, special equipment will be needed: a spray gun feeding liquid rubber under pressure through two channels.

Spraying liquid rubber should be carried out in calm, dry weather, at temperatures from five degrees.

The material is applied to the surface in even stripes (strip width up to 1.5 meters), up to 5 mm thick. To increase the protective function of liquid rubber (especially in places adjacent to drainage systems, weathercocks, parapets), a layer of geotextile can be laid.

Waterproofing with liquid rubber has several advantages:

- long service life (more than 25 years);

- fits well on any material (you can not even clean off the layer of old waterproofing, since liquid rubber fills cracks and cavities);

- surface elasticity, which prevents peeling and cracking of the coating;

- the strength of the coating with a thickness of 2 mm is comparable with the strength of a four-layer roofing material;

- possibility of application in different climatic zones;

- ease of installation;

- resistance to chemicals;

- the surface of the waterproofing layer does not swell;

- no additional heating of the material is required.

Do-it-yourself waterproofing the roof of the garage

High-quality waterproofing of the roof of the garage provides reliable protection of the room from dampness and moisture accumulation. This allows you to protect the car in the garage from corrosive processes.

Consider the option of waterproofing a flat garage roof using roll materials, namely roofing material.

preparatory stage

First of all, it is necessary to prepare the base of the roof. The old waterproofing coating is removed. The surface can be cleaned with a construction vacuum cleaner or using a compressor to drive the dust to one corner and collect everything with a broom.

If a layer of waterproofing material will be applied to a concrete base, it is advisable to remove cement milk by grinding. The attachment points of communication structures and plate joints must be cleaned with a hard brush (drill with a special nozzle).

The entire surface of the roof must be carefully checked for cracks and cracks. All defects must be cleaned and leveled with cement-sand mortar.

To perform the waterproofing of the garage, you will need the following materials and tools:

- ruberoid roll;

- bitumen emulsion;

- cement-sand mortar;

- spatulas and brushes;

- knife for cutting roofing material;

- roof gas burner.

surface treatment: screed leveling and emulsion application

On the area cleared of debris and dirt, it is necessary to carry out a screed under the slope (angle of inclination up to 4 degrees) so that precipitation does not accumulate in the puddles, but flows down the funnels. In addition, the screed will give additional strength to the roof.

After the screed hardens and dries, the roof surface is covered with a primer layer of bitumen emulsion.

garage roof covering with roofing material

The final stage of waterproofing works is laying of roofing material. For flat roofs, it is recommended to apply three layers of roofing material. The strips of each subsequent layer should overlap the joints of the previous one.

When rolling the roll, it is necessary to heat the underside of the roofing material with the burner. The image applied from the inside of the roofing material under the influence of temperature (gas burner) begins to deform, after which the coating can be rolled.

Stripes of roofing material are stacked with an overlap of about 10 cm.

Partial repair of the roof waterproofing layer

If the defects in the coating are minor (small cracks and bubbles), then you can make a partial repair of the roof, following a certain sequence:

- Use a hairdryer or brush to remove gravel that has crumbled from the edges of the damage.

- The edges of the defect must be raised (you can make a cross-shaped incision to make it easier to process the surface).

- The area at the site of bubble formation or cracks must be cleaned and dried.

- A layer of heated bitumen mastic should be applied to the exposed part of the roof and press the edges tightly.

- You can use the roller for wallpaper, so that the connection is more tight.

- You can eliminate the leak using special aerosols for repairing roofs. You can use it in cloudy weather.

- If the connection between the wall of the garage and the edge of the roof is damaged, then a lead apron can be used, which is fixed with cement mortar in the rows of masonry.

Waterproofing methods can be combined with each other, giving special strength to the structure and protecting all communication systems of the room from water and condensate.