Search

Login

Log House (Basic Information)

Wooden houses (chopped, paving, etc.) are houses with a low weight, ease of processing and construction. The main advantage of wooden houses is a wonderful microclimate.

Content

- Basic knowledge of building materials for the log house

- The rule of builders 11 arshins

- Types of log house

- Choosing log diameter

- Possible errors in the assembly of the log house

- Caulking video

- We build a log house under the roof video

To build a good log house is a rather expensive and difficult task.

For this work, it is often necessary to hire specialists from an unfamiliar company or co-workers.

In order to subsequently not have to break down the house or rebuild the house, you should be safe from unpleasant surprises; for this, it is necessary for the customer or future owner to keep certain knowledge in his memory.

Basic knowledge of building materials for the log house

How to choose a good log for the house?

Conventionally, a forest can be divided into three categories:

timber

Drill forest - tall, at least 24 meters trees with a small taper and a small number of branches.

Such a forest is used to make log cabins for houses and baths.

SNiPII- 25-80 clearly regulates: The runoff value of round timber when calculating structural elements should be taken equal to 0.8 cm per 1 meter of length, and for larch 1 cm per 1 meter of length.

To get a beautiful log house, experienced builders use a forest whose run does not exceed 0.5 - 0.6 cm per 1 meter.

sawlog

Logs are trees of medium, up to 24 meters high, the taper of such trees is much higher than the previous one, there are many branches.

This forest is used for the manufacture of lumber; it is not suitable for the felling of a large house, although a small felling of a house or a bathhouse can be made of it.

marketer

Undergrowth - trees up to 15-18 meters high with a small taper and a diameter of 11-20 cm.

Such a forest is called a tonometer, it is used to make a profiled beam, a rounded log, a quality lining, a floor rail and moldings.

It is also suitable for small buildings.

The rule of builders 11 arshins

When hiring carpenters, give them a little exam.

If to the question What is the difference between a winter swath forest and a summer swath forest?, They will answer that the first is drier - it’s better not to mess with such a team.

Since the main difference between the winter and summer felling forests is that the logs crack less during drying, as the moisture from the wood simply freezes, which means that the installation of the log house and its finishing can begin earlier.

Professionals do not advise to put a house out of logs, although it looks attractive.

Since the machine cuts the young wood surrounding the ripe wood, cuts it inaccurately - somewhere more, somewhere less, the durability of the log house does not betray it.

When building a house measuring 8x8 meters or more, be aware of the rule “11 arshins, which reads: if the length of the wall is greater than or equal to 11 arshins (approximately 7.8 meters), then such a wall must be pulled together with a major wall. That is, you need to make a five-wall, and maybe a six-wall, depending on the size of the house.

Types of log house

The corners of the log house are cut either in the paw, without releasing the ends, or in the bowl with the release of the ends.

The traditional length of the ends is two log diameters.

This is justified by thousands of years of experience, although now some experts make the ends short.

A house, chopped with the production of ends, is warmer, but will cost more, since more forest is needed.

A house felled into its paw is colder, and the ends of the log house will need to be sewn up with overhead boards, as the sawn wood decays quickly.

Which way to choose the best, decide the owner. Each owner of the future home has his own ideas about his appearance. Often, the method of cutting a corner is determined only from an aesthetic point of view, houses felled into a corner look more traditional, and in a paw-modern.

In general, this is a matter of taste.

in the paw

A house cut down in a paw must be cut inside for subsequent cladding or for a planer. Under the wall sheathing, the cabin of the corner into the bowl can be cut not as carefully as under a planer.

When cutting a corner into a paw, the log must be stacked in brackets, aligning along the outer edge and squeezing the excess from the inside, and not in the center of the log, that is, the wall thickness should be the same over the entire height, then from the outside it looks like it was cut down from a calibrated forest.

The most common way to cut into a paw is to cut into a slanting paw, or dovetail. This method is suitable for the construction of hozblocks, livestock yards, since such a connection does not hold heat well.

in the paw with a tooth

When constructing a residential building, use a corner cutting in a straight paw with a tooth. In this case, the tooth, as well as the tooth in cutting the corner into the bowl, allows you to better keep heat in the house.

Those. tooth and preseka does not allow a through passage of air from the street to the apartment building, but creates an additional obstacle to the cold.

Felling a house in a corner is considered easier for carpenters, since the logs are laid on top of each other in the center and not in brackets.

In this case, the forest is selected very painstakingly, otherwise, due to the difference in the thickness of the butt (this is the part of the log closest to the root) and the top, the house will look sloppy.

However, using a tilting, you can make the logs almost perfect, but the tilting is not cheap and not every carpenter will take it.

Now consider the most common ways of cutting into the corner. Often they speak in a bowl or in a cloud, but these methods differ from each other.

into the bowl

When cutting the corner into the bowl, a notch is made on top of the logs.

This is the simplest and cheapest, and therefore the most common way of cutting into the corner. With this method, the walls must be left round, not hewn.

But such a method, the so-called household bowl, is not permissible during the construction of a house or bath, since all the heat in the corner will be kept due to the insulating material laid between the logs.

A warmer angle is obtained by connecting the logs into the bowl with the cutter, i.e., a notch with a platform in the middle is made on the lower log, and a log with a hollow in the middle is placed on top.

in the cloud

But when cutting a corner into the cloud, a log is made from the bottom of the log, and the upper log is laid with a notch with a ledge.

This method is more complicated and more expensive and in this case the walls inside the house cannot be cut through: as in the case of cutting the corner into the bowl, it is necessary to make a stop.

Choosing log diameter

Consider the following question: What should be the diameter of the log?

In the middle lane, drill forest is cut at the age of 80 to 120 years, in the northern regions from 90 to 140 years.

If you have a choice, it is best to build a house for permanent residence from logs with a diameter of at least 22-24 centimeters.

When building a house in the middle lane, the grooves on the outer wall should be 9-12 centimeters wide, in places where the temperature in winter drops to -30 degrees and below -12-13 cm, at -40 degrees below zero -14-16 cm.

When buying a finished log house, be sure to check its quality.

The correct frame can stand on the foundation all winter until assembly, and for the rest of the year no more than 3 months.

Possible errors in the assembly of the log house

The ideal option is if the log house is assembled by the same team that chopped it up so that there is no one to transfer responsibility.

Make sure that carpenters do not drive large nails into corners when assembling the log house, which some carpenters practice in their work.

Such a house will have to be disassembled in a year, pull out nails, and sometimes make a groove in a new way.

There should not be any metal in the tree, it is a source of moisture, and subsequently rotting.

To fix the logs, use dowels (wooden rods connecting the logs), and only where necessary.

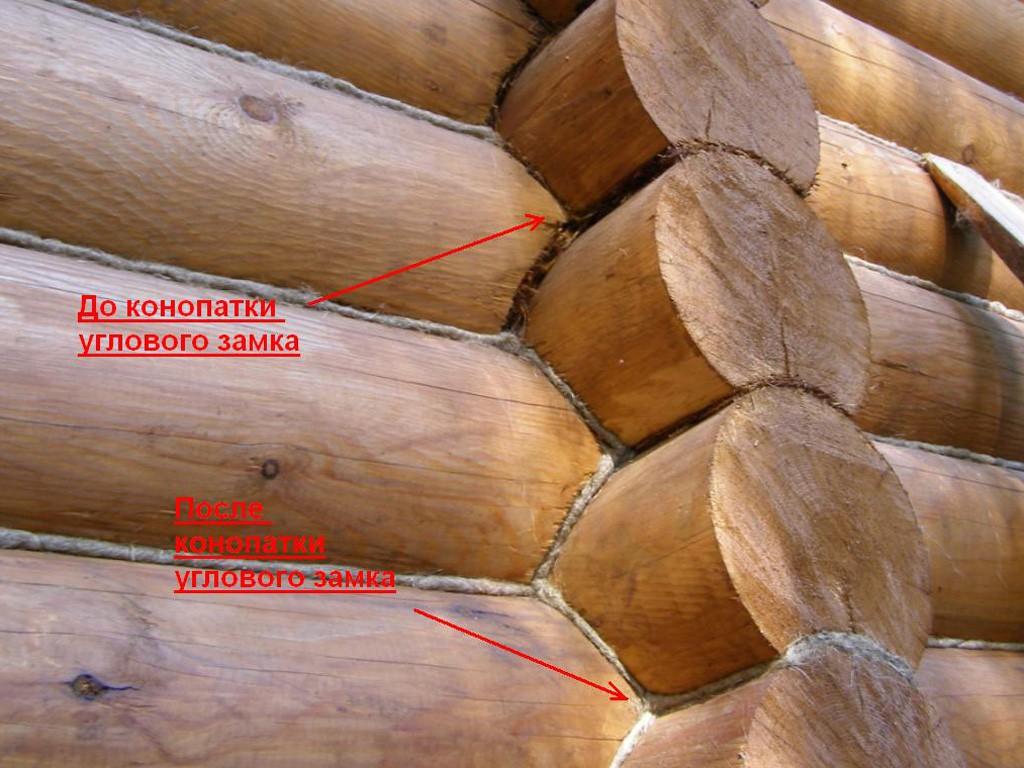

Caulking

Floor beams and rafters in a well-cut house are cut so that the walls hold tight in corners and grooves.

Excess holes in the logs lead to premature aging of the house.

For primary caulking caulks of seams are advised to use loose mossphagnum with a layer of at least 50 mm.

When assembling a log house in winter in frost, apply flax.

Modern wool seals are unsuitable because of the moth, they do not use polyurethane foam at all.

We build a log house under the roof

The house is built in two stages under the roof.

Due to the fact that the geometry of the roof after shrinkage of the log house can change, which can lead to damage to expensive roofing materials, first they make a temporary roof from roofing felt.

In the future, this roofing material can be used, for example, making a black floor.

On the foundation and under the roof, the log house shrinks, so any finishing work can be done no earlier than after 6-12 months.

And do not believe the firms that claim to use the latest technology to speed things up. No new technologies have been invented for this.

Openings for windows and doors are cut after shrinkage of the house.

Where it is planned to put the door, you can make a hole in the wall by cutting 3-4 crowns.

You can hang ceilings and floor only after shrinkage of the log house, otherwise the ventilation of the house will deteriorate and fungus or mold will appear on the walls inside.

All other work can be done after the log house has stood.

Tip

To prevent the window or door block from deforming, products with a joint thickness of at least 10 cm are suitable for a log house.

When installing the jambs, do not use either metal or wooden nails, so that they do not interfere with the logging, the cracks fill the tow.