Search

Login

Recommended

What is polystyrene foam, the main properties and characteristics of this material.

The climate of Russia forces us to use all possible insulation materials. The most popular option is polystyrene. Due to its unique thermal insulation properties and reasonable price, polystyrene is the most affordable material.

Content

- What is polystyrene foam and where is it used?

- Its properties and main characteristics

- Advantages over other types of insulation

- How to choose the right foam

- How to lay foam video

What is foam

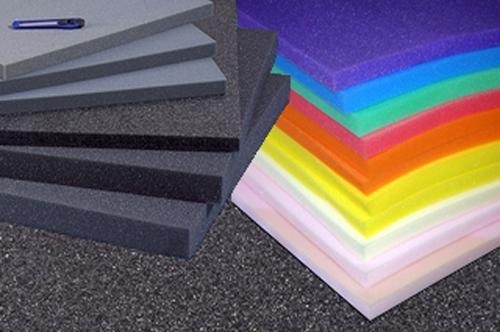

Polyfoam is one of the types of insulation, it is used for both internal and external wall insulation. The internal insulation of the walls with foam will provide you with an excellent result. This material is almost 100 percent air, a few percent are polystyrene cells that have been foamed. Such material is used everywhere, because It is completely environmentally friendly. Under the foam can understand a lot - these are various polymeric materials that have similar properties.

polystyrene foam

Polystyrene is a type of polystyrene that is found in boxes with household appliances. Polystyrene foam is a lot of balls that were fastened together. Fairly cost-effective way of insulation. Walls, ceilings and floors are not the only possibilities for using polystyrene.

polyethylene foam

It is a translucent and soft material. Food packaging is made from it.

polyvinyl chloride foam

This is the type of foam that relates to non-combustible materials.

polyurethane foam

Foam rubber is elastic and breathable material. Such a foam is widely used in the manufacture of furniture and insulation of window structures.

Properties and main characteristics.

Polyfoam has unique insulation properties.

1. Thermal insulation. Good thermal insulation of this material is achieved by the presence of air in its composition, since air is already an excellent heat insulator, and due to the special structure of the cells, the heat does not go outside.

2.Compatibility polystyrene foam with other building materials, which means that various plasters and plaster mixes can be used for insulation.

3. Durability This is an equally important indicator. Polyfoam is very durable and resistant to our harsh weather conditions. However, the only one who can damage the foam is rodents. The service life can reach 50 years under normal climatic conditions.

4. Fire resistance achieved by the addition of special ingredients to the foam composition flame retardants that suppress fire.

5. Excellent soundproof properties achieved due to the porosity of the material, so it can act as a ceiling foam.

Advantages over other types of insulation

Today there are many types of insulation, but the most popular is foam insulation and mineral wool. So what’s better, mineral wool or polystyrene:

1. Ease of installation. Usually, the installation of polystyrene does not require any skills and special knowledge, but when insulating the wall with mineral wool, one must take into account that the air gap must be observed, i.e. the distance from the wall to the mineral wool should be 2-3 cm.

2. Ability to breathe - this is an equally important advantage of polystyrene over mineral wool, therefore, polystyrene is used mainly not only in wooden baths and houses, but for insulation of facades.

3. The ability to pass steam. The use of mineral wool in a bath without vapor barrier is not the best option, because mineral wool will quickly become saturated with moisture, which will render it unusable. But in this regard, polystyrene is what you need.

4. The only drawback when warming the bath with this material is polystyrene cutting, since many simply do not tolerate a terrible creak during the execution of work, but because it will take a long time to cut, then you should think about choosing this type of insulation.

5. Which is warmer. The answer to this question is a little more difficult. On the one hand, it can be said that mineral wool is a kind of fur coat, but when referring to professionals, the general design with foam can be no worse, this is achieved due to the thickness of the foam. It is worth noting that for cotton wool it is additionally required to buy a vapor barrier, which will lead to unforeseen expenses.

How to choose the right foam

It is worth approaching the choice of polystyrene with all responsibility. Follow the following rules, and you will choose a good polystyrene for wall insulation:

1. Before you buy polystyrene, think about why you need it, it will depend on what its density will be. So, for the insulation of walls under the lining or drywall, a foam with a density of 15 kg / m3 is suitable, and when warming the walls outside 25kg / m3. In addition to walls, foam can also be used to insulate the ceiling and floor for additional sound insulation, then the density is 35 kg / m3.

2. Storage location. It is very important to think over where this building material will be stored until its further implementation. If it is open air, then the foam will lose its thermal insulation properties.

3. At the time of purchase, ask the sellers all the necessary documents for this insulation. In this case, you will be sure of the quality of the goods.

4. The color of the foam should be white, if somewhere it has changed its color, then we can safely assume that this is a poor-quality product. Also, nothing should be exfoliated from the foam.

5. Ask the seller to weigh the pack with foam. After that, make simple mathematical calculations and calculate the weight of one cubic meter. (minimum weight 15 kg).

6. Feel the foam. High-quality material should be soft and elastic, if this is not so, then it is better not to make a purchase.

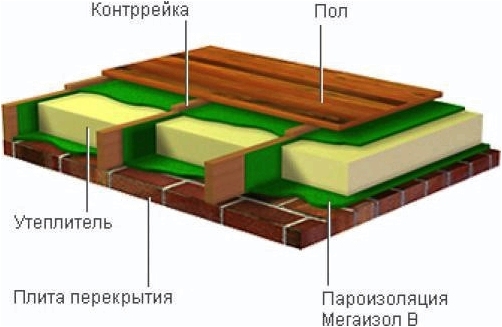

How to lay foam

Firstly, it is worth preparing the walls, i.e. it is required to level them, the old paint needs to be smoothed out. After applying the plaster to the cleaned wall, you need to go with a primer. Before gluing the foam itself, you need to give it a roughness on one side, i.e. walk with a needle roller.

Glue can be applied both to the wall and to the material itself. Work should begin from below, this is required so that in the future the material does not slip. Stacking is done with the letter T.

After fixing the foam, you need to additionally strengthen it with the help of special dowels.

The joints between the sheets of foam should be treated with mounting foam, and after drying, remove excess.

Foam packing is a simple matter, but its implementation should be taken seriously.