Search

Login

DIY thermal insulation

In the modern world, the most important issue is cost savings in the form of energy conservation, and this requires the use of modern materials for thermal insulation.

Content

- Water heater insulation

- Pipe insulation video

- Installation of reflective foil screens behind radiators

- Eliminate Drafts

- Thermal insulation for walls video

Water heater insulation

We, as ordinary people, believe that the water heater itself is a source of heat, therefore it is good when its external walls are not insulated and are an additional source of heat and if it is installed in the room where the clothes are dried, the heat coming from it is used for needs completely. But in fact, it is necessary to insulate the water heater, as it emits too much energy, and this is an additional source of costs.

Thermal insulation of a water heater can be done by yourself.

On modern water heaters, an external thermal insulation from foam materials has already been made, but we are talking about old models that do not have external thermal insulation. For insulation, it is necessary to purchase mineral fiber, or foil insulation, with a thickness of 75-100 mm.

After measuring the approximate height and circumference of the water heater, add about 20% for unforeseen circumstances, evenly distributing the fiber across the water heater, you need to fasten the edges.

Around the circumference (top, center and bottom), secure the future cover with a strapping material. It is impossible to tighten the cover too tight, you must leave a gap for free thermal movement.

It is necessary to insulate pipes, especially ventilation pipes, above the heater using the same method.

Pipe insulation

It is necessary to make insulation of pipes with hot water when transporting water to its destination, i.e. in those areas where heat does not perform the function of heating rooms (for example, pipes are laid under the floor of a house), by isolating them, you thereby reduce heat loss.

It is also necessary to isolate pipes with cold water if they are laid in unheated areas of the house and can freeze. For insulation, you can simply wrap the pipes with a heat-insulating bandage, and some types of coating with reflective foil.

But usually, for thermal insulation with your own hands, it is convenient to use foam tubes, they are specially designed for these purposes. Often, pipes are located close to the walls and wrapping these pipes is rather inconvenient, in which case foam tubes come to the rescue.

Such foam tubes used for thermal insulation of pipes are available in various sizes. This makes it possible to apply them to pipes of different diameters, the thickness of the tubes is from 12 to 20 mm.

Some tubes are equipped with a foil, the use of foil contributes to the partial return of heat emitted by the pipe. Most tubes, so that they can be worn on pipes, are cut in length in advance.

Having put pieces of tubes on the insulated section, connect them to the joint, seal the joint with duct tape from PVC.

If necessary, apply thermal insulation to a bent pipe. To do this, cut out small triangular sections on the bends of the insulation, along the length of the cut - this allows you to avoid wrinkles when bending. Put insulation on the pipe and seal the connection with PVC tape.

If it is necessary to insulate two pipes connected by a square, i.e. the pipes are rotated 90 degrees, it is necessary to make a cut at 45 degrees at the ends of two sections of the insulation pipes, then join them and seal them with tape.

In the place of the T-shaped pipe joint, join the insulation in the upper part with a wedge-shaped inset and also seal with tape.

Installation of reflective foil screens behind radiators

About 25% of heat loss occurs when the radiator is placed next to the outer wall and the heat goes into this wall.

If behind a radiator to make a wall lining, Tepofol laminated with foil (this is reflective thermal insulation), you can return part of the heat. This heat insulator is in rolls, sheets, in the form of tiles. A heat insulator reflecting thermal insulation is laid at a time when the radiator is removed for repair or painting, but can be done with the radiator installed.

By measuring the dimensions of the radiator, a heater is cut out, the dimensions of which are slightly larger than the dimensions of the radiator, the locations of the mounting of the brackets to the wall are marked, with a sharp knife, make narrow slots in the heat reflectors to put the reflector on the brackets.

On the back of the material, apply glue for heavy wallpaper, then paste it behind the radiator. Using a wooden plank, flatten the sheet on the wall, you can use a small roller. When fixing such thermal insulation, you can use double-sided tape.

Eliminate Drafts

A highly effective way to reduce heat leakage to the outside is the anti-tamper seal on doors and windows, and this is a relatively cheap way. Drafts passing through minimal gaps, joints between skirting boards and floors, gaps in the floor, gaps between the ceiling and walls and even through outlets take away a huge amount of heat.

To prevent heat loss, it is necessary to seal as many slots as possible, to exclude all cold bridges, but the achievement of this goal depends on the type of wall construction, their decoration, the method of laying communications, the age and condition of windows and doors.

Before eliminating drafts, it is necessary to identify them. To do this, light a candle and bring it to the place of the supposed passage of cold air. By the fluctuation of the fire, you will determine the place to be insulated. For insulation, various sealants are used, which we will discuss in the next article.

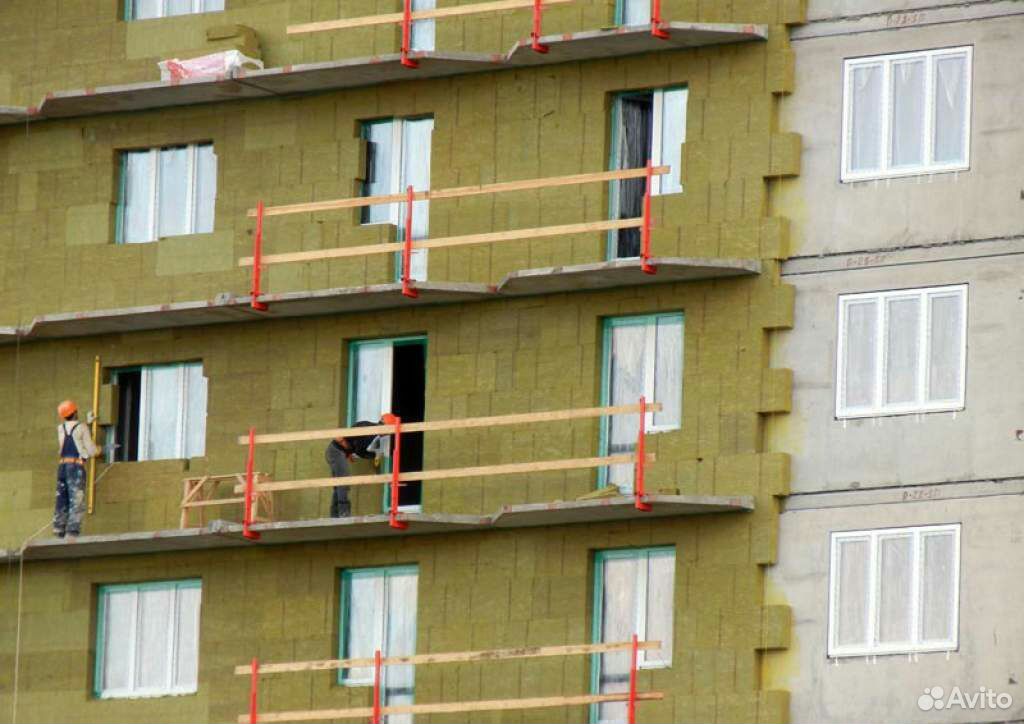

Thermal insulation for walls

Various options are possible for thermal insulation of walls, one of which is thermal insulation of cavities - this is the most economical way of insulation for houses with an individual heating system.

Currently, when constructing a new house, builders immediately turn on a heat-insulating layer between the walls of lightweight masonry or blow heat insulation into the cavity before the internal plastering of the walls. But in the past, many houses were built with unfilled cavity walls of lightweight masonry.

In order to eliminate these cavities, an experienced specialist is required who can introduce thermal insulation through a hole in the wall. The most common type of blown thermal insulation is mineral fiber (stone or glass wool). You can also use polystyrene foam in the form of white or gray granules, glue is blown along with polystyrene foam, it binds the granules and prevents them from caking in the cavity.

Work on the injection of thermal insulation should be carried out in 2-3 hours and carried out outside the building, while the master conducts various checks and tests from the inside.

Holes are drilled through the masonry seams of the outer walls, and also drilled near doors and windows. Then, in each hole, the compressor hose is inserted and the insulation is pumped in, after filling, the hole is closed.

In addition to the isolation of voids, the external walls are thermally insulated, internal cladding is possible, while the rooms that need maximum improvement are optionally thermally insulated.

The inner lining, under the strength of the homeowner himself, all other work on the thermal insulation of the walls is carried out by professionals.