Search

Login

Recommended

Do-it-yourself garage

The garage on the plot can serve both as a workshop, a storage for garden tools and a place to create a cellar.

Content

- General information video

- Garage foundation construction

- Concreting the floor

- Garage Walls, Roof

- Garage Interior

- Useful Tips

- Carport

- The construction of the cellar in the garage

- Wooden garage video

General information

Garages can be wooden, metal, brick.

Since wooden garages do not meet fire safety requirements, and in metal garages there are no normal conditions for storing the car: it is hot in summer, condensate forms in winter and autumn, the cause of corrosion, the most optimal option is to build a brick garage. Making metal doors with your own hands for such garages is the best option, but you can also use custom-made doors. The garage must be equipped with ventilation, lighting, and racks for storing various tools. The garage must be dry, the optimum temperature is 5-15 degrees Celsius, relative humidity 50-70%.

Garage foundation construction

After choosing a place for the garage, if possible, you can build close to the house, so you will save during the construction, you will have to build less on one wall.

When building a garage to the house, it is necessary to ensure that the general architectural appearance of the building is not disturbed.

Each structure begins with digging a foundation pit. In dry sandy soil they dig a pit under a foundation 60 cm deep .; in clay soil - 80 cm.

Concrete is laid in the trench of the pit, into which broken brick, crushed stone, metal scraps can be added. The necessary fasteners are installed before the concrete has hardened.

Concreting the floor

A layer of sand 10 cm thick is poured onto the floor area, compacted, a roofing flue is applied on top, a concrete layer 10–12 cm thick is evenly distributed over the roofing felts, the surface should be of uniform thickness with a slope towards the gate.

To facilitate this work, it is recommended to lay wooden planks with the desired slope in the longitudinal direction along the walls.

Next, focusing on these planks, take a board on the edge and align the entire surface with it. Then the planks are removed, and the concrete surface is rubbed with a grater.

Garage Walls, Roof

A garage has proved itself well, the walls of which are folded into a brick floor, with corner and intermediate posts in one brick.

The niches that are obtained between the posts inside the garage can be used to equip shelves and shelving.

The roof of the garage is single-pitched, gently sloping of wooden beams, placed on an edge and resting on poles, with continuous sheathing of boards with a thickness of 40-50 mm.

Roof waterproofing - roofing material in three layers with hot bitumen pouring. The roof is covered at the discretion of the owner or slate, or metal profile.

Garage Interior

goal

The internal dimensions of the garage are 9.5x5.2 meters, this allows you to rationally use the space along the walls.

The door leaf consists of a frame, sheathed with boards - lining, the door size is 185x170 cm., In one of the leafs there is a gate with external lock.

Currently, the gate market is very diverse: roller shutters, automatic, sectional, etc.

ventilation

Ventilation is provided by an asbestos-cement exhaust pipe with a diameter of 150 mm. with nozzles and a cap.

The lower end of the vent pipe is closer to the floor.

manhole

The floor is cement with a viewing hole and a basement.

The garage on the plot, in addition to its direct purpose, can serve as a place for the home workshop and cellar.

Warming of a brick garage is mandatory if the machine is operated year-round.

The width of the inspection pit should be 10-15 cm. Less than the distances between the wheels of the car, and the depth should correspond to the height of the person so that the person can work without bending.

The length of the inspection pit should be 1 meter longer than the machine to ensure free entry and exit.

The walls and floor of the pit are concreted, metal corners are fixed on the upper edges so that the wheels do not slip.

If you want to install lighting in the inspection pit, it must be taken into account that the voltage should not be higher than 36 volts, the lamps for the inspection pit must be tight.

floor

The floor in the garage must withstand mechanical stress for a long time, be resistant to oil and gasoline.

In view of this, when pouring the floor, it is necessary to use cement grade not lower than M500.

It is good to attach a soft shock absorber to the rear wall of the garage, at the height of the bumper of the car, to protect against possible impacts when entering the garage.

Useful advice

Before pouring concrete in the garage floor, it is necessary to make an inspection hole. those. the inspection pit is bricked (in half a brick), concreted, and then concrete concreting work is already underway.

A large metal corner is fixed along the edges of the pit.

In a corner of the pit, I dug a hole for draining water the size of a bucket, put a grate on top of it, water is collected, the grate is removed and the bucket is removed.

To close the pit, a board of 40-50 mm is needed. Boards are sawed along the width of the pit.

When the pit is not needed, it is closed by boards that lie on a metal corner. A metal ladder is used to descend into the inspection hole.

Carport

If the stay on the plot is seasonal, i.e. the warm season, it does not make sense to build a capital garage, you can do with an ordinary canopy.

The height of the canopy is 2-2.5 meters, the roof is pitched.

The beams or beams are supported on racks located around the perimeter of the site with a pitch of 1.5 meters; metal beams with a diameter of 30-40 mm., Beams of 100x100 mm., Logs with a diameter of 100x120 mm are suitable for beams.

Before digging in the beams, they are coated with bitumen and wrapped with roofing felt, then they are buried to a depth of 70-80 cm, then it is necessary to tie the perimeter with 25 mm thick boards, the gates are also made of boards.

Building a cellar in a garage

waterproofing

When building a cellar, you can not save on waterproofing and ventilation.

It is necessary to build a cellar simultaneously with the garage, the walls of the cellar serve as the foundation for the garage and are laid out from concrete blocks.

If necessary, the basement can be overlaid with brick, laying it flat.

Carefully waterproof the walls and basement floor.

If roofing material was used as a roofing material, the seams between the sheets must be welded.

It’s good to lay a couple of layers of fiberglass on top: it sticks to the tar, increases its durability.

ventilation

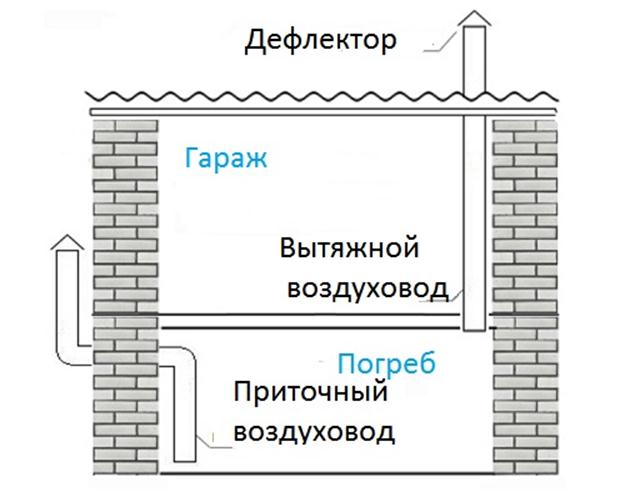

When laying the last rows of the basement, immediately determine where to position the ventilation pipes. The ceiling in the cellar, as well as the hatch, it is advisable to make it well insulated.

If the cellar ceiling is slanted by placing a chimney in the highest part of the ceiling, there will be less condensation.

If possible, close the entrance to the cellar with two covers, between them an air gap forms - an additional heat insulator.

The second ventilation pipe, placing it in the opposite corner from the main hood, is taken to the garage.

The bottom edge of this pipe should extend almost to the basement floor.

By the way, it is worth making removable part of the hood protruding above the roof of the garage, and if it grows frosty in winter, it will not be difficult to clean it.

interior finishing work

The basement walls are most easily plastered with cement mortar (1 part cement, 4 parts sand) and whitewashed with lime. Basement floor concrete with metal fittings.

The base is a slightly compacted crushed stone (10 cm.) And sand (5 cm.), In the center is made a recess where condensate is collected.

The supports for the shelves in the basement are made of metal, removable boards treated with an antiseptic are laid on them.

For safety, the basement should only have low voltage (12 or 36 volts).

Wooden garage

With a seasonal stay on a summer cottage, a wooden garage can serve as a good option besides a canopy. Under it does not require a foundation and a special site.

Such a garage can be put directly on the ground by placing blocks or paving slabs under the base.

If you level the site and lay it with paving tiles, this would be an ideal option.

You can put a garage directly on the tile.

Such a garage can be built using Finnish technology - this is when walls are built without nails using special locks on the boards.

Such a garage is much cheaper than a brick one and looks very beautiful and harmonious. And you can build a garage by using a beam and edged board.