Search

Login

Recommended

Fence on screw piles, how to install such a fence, installation technology

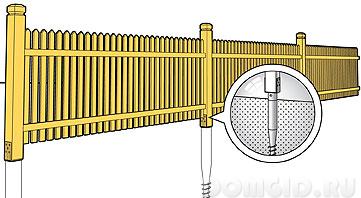

Each owner who at least once thought about erecting a fence on his personal territory, plans not only to build a durable and reliable fence, but also to do it as efficiently as possible from a financial point of view. Installing a fence on screw piles is the best way to implement the above wishes, thanks to which you will become the owner of a reliable and durable fence with minimal financial investment. Screw piles, which are successfully introduced in suburban construction, contribute to the construction of an effective support even in areas with problem soil.

Content

- Fence on screw piles. Main advantages

- Features of mounting the fence on screw piles video video

- Technology for mounting the fence on screw piles: marking the territory and screwing the piles

- Fixing panels from corrugated board. Key Features video

Fence on screw piles. Main advantages

The popularity of screw piles used in the construction of fences is due to a number of advantages that must be mentioned:

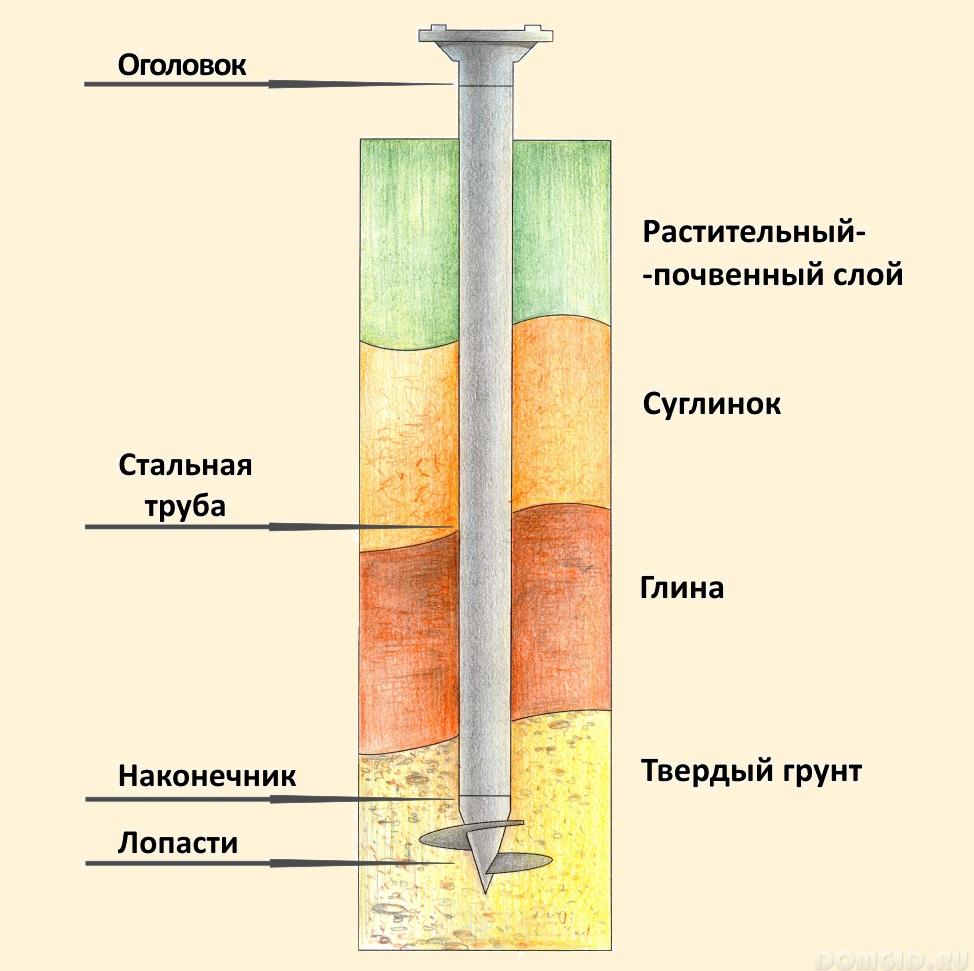

1. The possibility of installation in areas with problem soil: a fence, the design of which implies the presence of screw piles, can be built not only on loams and peatlands, but also on soils with a high level of occurrence of groundwater. Installation of the fence on piles can be carried out even on slopes characterized by a sharp difference in elevation, and areas with complex terrain;

2. The possibility of building a fence at any time of the year, since the installation of screw piles can be carried out in any weather conditions, even in areas where permafrost reigns;

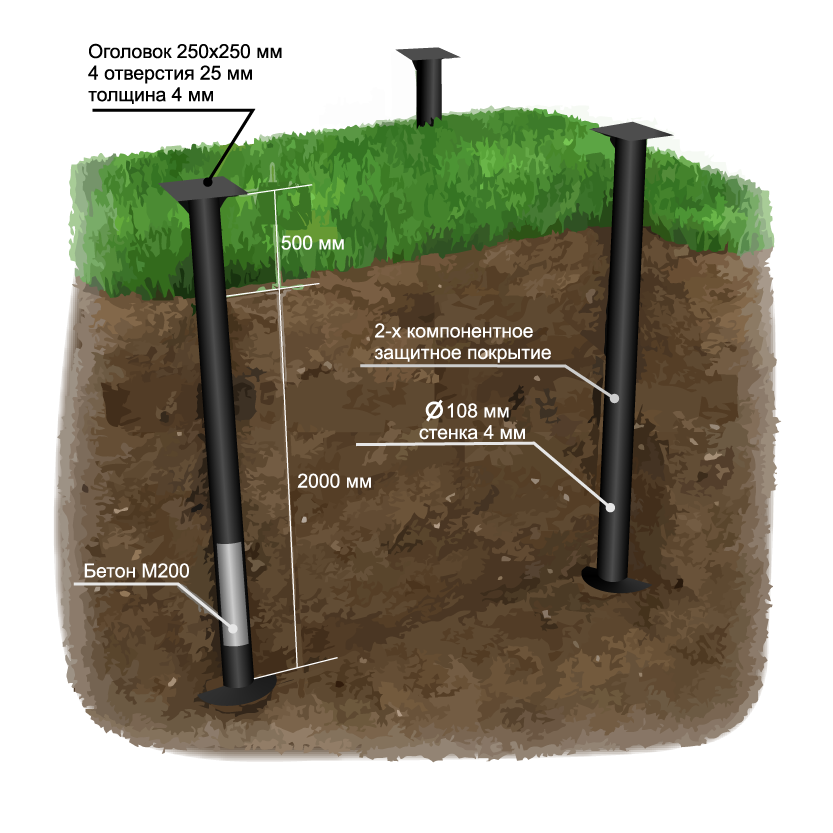

3. Ease and speed of installation. The design of screw piles for the fence is represented by metal pipes equipped with cast or welded tips.

They, like screws, are simply screwed into the ground, which is done manually, without the use of specialized equipment. At the same time, screwing up one pile takes no more than 20 minutes.

4. Duration of operation. The service life of screw piles exceeds half a century, and if the metal structures are pre-treated with an anti-corrosion compound, they will last more than 100 years;

5. The acceptable cost of the fence on screw piles, which is characterized by an optimal ratio of price and quality.

Features of mounting the fence on screw piles

As for other types of construction work, for the installation of the fence on screw piles their own nuances are characteristic. What kind? Let's consider further.

1. Before starting installation work it is recommended to carry out a test screwdriving, which will determine the required level of penetration, depending on the qualitative characteristics of the soil;

2. The possibility of screwing in metal structures both manually and mechanically, due to which the piling can be deepened without making additional holes;

3. Regardless of the method of penetration, screwing the piles must be carried out until they reach the maximum hard ground layer. For these purposes, structures are constantly lengthened using couplings.

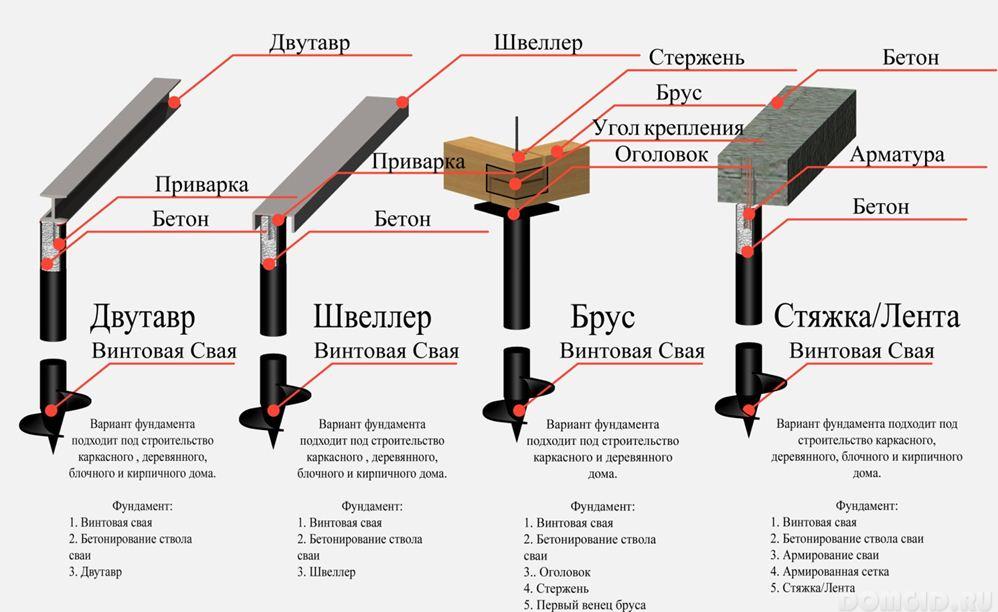

4. After the installation of the screw piles for the fence is completed, they are trimmed to the required level, and subsequently poured with concrete mortar, which will prevent the penetration of moisture and increase the stability of the structure;

Technology for mounting the fence on screw piles: marking the territory and screwing the piles

Fences on screw piles, reviews prove this, can be made from a variety of materials, including:

1.Proflist;

2. Brick;

3.Tree;

4. Mesh and forged items.

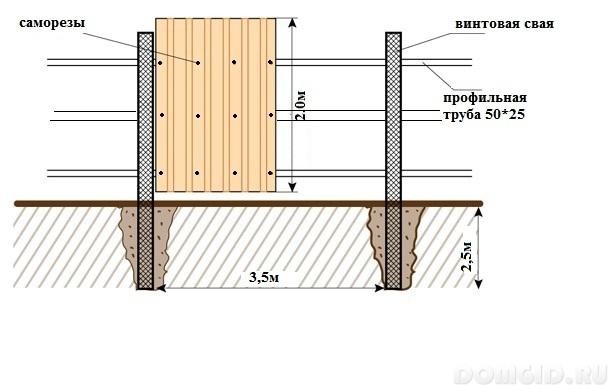

The most common options are recognized as a wooden fence on screw piles and structures made of profiled sheet. Brick fences on screw piles are less common in suburban construction, since their installation is characterized by the greatest labor costs. In this case, the frame of both of them is performed according to a single scheme, which must be taken as a basis for the construction of the described construction.

Marking the area around the perimeter is an important stage in the preparatory work, which must be approached with due care. When choosing a site, it is important to consider the availability of nearby communications and to position the fence as far as possible from them. It must be remembered that the supporting piles should be located at a distance of 2-3 meters, however, the optimal step is 2.5 m. To determine the required depth of screwing the posts, carry out a test screwing. It is important to consider that the minimum screwing depth should be at least 1.5 m. Follow this axiom in order to subsequently eliminate the skew of the structure with the onset of cold weather.

After proper marking, in the soil make recesses (15-20 cm), which are necessary for screwing piles.

If you plan to screw the piles manually, it is advisable to construct a kind of two-sided lever from an ordinary pipe, the length of which should be at least 2-3 meters on each side.

In the process of screwing piles, it is necessary to monitor their strictly vertical location with the help of the construction level, otherwise it will be practically impossible to correct the deficiencies later. This is due to the fact that if an unwanted tilt is detected, the structure will have to be removed from the recess and screwed in again.

When reinforcing the pile, it is necessary to screw it in until its maximally deepened end reaches hard soil. It is not difficult to determine this: if the pile has reached the hardest soil layer, the place of its connection with the lever will undergo deformation at the slightest effort.

The essence of the next step is to cut the piles to the desired size and then pour them into concrete. If the need arises, minor pits are organized around the piles, subsequently filled with concrete mortar, which contributes to a more solid reinforcement of the piles in a fixed position. But these measures are considered secondary, and their implementation is practiced more often in the process of building houses. When erecting a fence, you can completely do without them. Anticorrosion treatment is carried out at the same stage.

The nature of subsequent work depends on the length of piles left on the surface.

1. If the length of the surface of the pillars is from 1.5 to 2 meters, installation of the guide rails is carried out;

2. With a length of 30-60 cm, fence posts are installed.

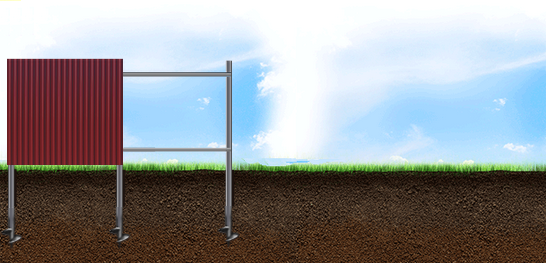

Fixing panels from corrugated board. Key Features

If you plan to mount the fence from corrugated board, you must install at least two guides, one of which will be the top and the second the bottom.

Their installation can be carried out in two ways, one of which consists in welding the guides to the supports, and the second in screwing to the posts by means of bolts. If you prefer the second, then in the places where the guides pass to the pile, weld corners from metal, which are equipped with holes for fasteners.

In conclusion, they are determined with the desired stylistic direction of the fence, since the method of installing corrugated board depends on this.

Most preferred is the installation method of the panels, which assumes that they are parallel to the columns. Before fixing the original sheet, careful measurements are preliminarily carried out, since otherwise, skewing of the panels is inevitable. When installing the first panel, make sure that the corrugated sheet is at a distance of 5 cm from the ground level, otherwise it will soon significantly reduce its functional characteristics.

When installing panels, experts recommend that the following sequence of work be observed:

1. First, determine the distance from the soil level to the lower edge of the panels and at a specified height stretch the construction thread;

2. Having ascertained the correct installation, carry out the installation of the first panel;

3. The alignment of the next sheet is carried out in accordance with the previous one, after which they are fixed;

4. The above steps are repeated until all sheets are fixed.

Having completed all the stages of installation, as well as following all the tips, you can be sure that the fence will be not only functional, but also as aesthetically pleasing as possible.