Search

Login

Recommended

Heater under linoleum, which heater is laid under linoleum, how to choose a heater under linoleum

Choosing flooring is becoming increasingly difficult. A huge assortment of materials on offer is amazing and compels us to spend precious time in doubt and comparison. However, there is time-tested material that does not lose its popularity and is in deserved demand by consumers. We are talking about linoleum, which, with properly laid insulation, is quite capable of competing with the famous underfloor heating.

Content

- How to choose a heater for linoleum

- Ways of laying insulation under linoleum

- Do-it-yourself laying linoleum on a wooden floor

- How to lay linoleum, linoleum laying technology video

- How to lay linoleum with your own hands on a concrete floor

- Leveling the floor with plywood for lags video

How to choose a heater for linoleum

It should be noted right away that there are such types of linoleum that are originally produced with an insulating substrate. The top layer in them performs a decorative and practical function, forming a waterproof and wear-resistant coating, and the bottom consists of felt or jute. Unfortunately, it is unlikely that such a linoleum can be laid on concrete floors, since the insulation layer is too thin and this type of flooring is suitable only for wooden floors.

As an additional insulation for the floor under linoleum, it is most often used:

Roll cork, which has a whole range of advantages. This material perfectly holds its shape and protects linoleum from bursting, it also retains heat well and is moisture resistant.

Jute insulation obtained from the processing of natural fiber. Most often, linen and wool raw materials are used to produce this type of material.

Liquid heaters are a special type of paint that forms a reliable heat-insulating layer with a porous structure.

Roll foam, a special type of foil material based on polyethylene foam. An additional advantage of this material is the foil layer, which has waterproofing and reflective properties and a self-adhesive inner surface, which allows you to reliably fix penofol on the floor.

Mineral wool and glass wool. Two types of these heat-insulating materials occupy a strong leading place in the building materials market. In addition to preserving heat, these materials have soundproofing properties that suppress all noise.

When deciding what kind of insulation to put under linoleum, you should be guided by the humidity in the room and the amount that you plan to spend on thermal insulation.

Ways of laying insulation under linoleum

Laying insulation on a concrete floor using the even coating method is a simple and uncomplicated process. In order to prevent the spreading material from absorbing moisture given off by concrete, a layer of a waterproofing film is laid (simple polyethylene can be used) and insulation is laid directly on top of the film. The joints are glued with construction tape, after which you can roll out linoleum rolls and connect them.

Application of liquid insulation (heat-insulating paint) is carried out on a pre-dried and carefully leveled concrete floor. The application process is similar to the floor painting technology, so it’s enough just to evenly distribute the liquid thermal insulation on the floor surface and wait until it dries. Then, a plywood coating is laid on top of the insulation, after which linoleum can be laid.

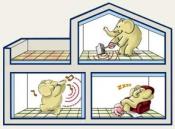

Warming with lags is a much more complicated method, but floors with this method of thermal insulation will never be cold. For this option, it is necessary to equip the log system, in the intervals between which a heater is laid. From above, this structure is covered with a layer of chipboard, and then fiberboard is laid. For this method, you can choose any suitable insulation for linoleum, the price of which is not too high.

Do-it-yourself laying linoleum on a wooden floor

Not every homeowner will invite a specialist to find out how to lay linoleum on the floor. It is quite possible to deal with this process on your own, without spending extra money on calling the master.

Before laying linoleum, it is necessary to carefully prepare the board surface for the floor covering. It is necessary to immediately identify the places where the differences and irregularities are most noticeable and mark them with a marker. Boards with a creak should be additionally pierced with nails or self-tapping screws to the logs. Hats from nails need to be deepened as much as possible, this can be done with a hammer and a beard, and the nail should go into the wood to a depth of about 5-7 mm.

After all the hats of the nails are deepened, you need to smooth out all the bumps and swings of the floor. You can do this with a simple planer, but the parquet grinder is best suited for these purposes. It is best to start processing the floor from the marked places, this will immediately help determine the amount of upcoming work and the thickness of the layer to be removed.

After the floors are leveled, it is necessary to remove all debris and put sheets of plywood (thickness not more than 12 mm), which can be fixed with PVA glue. Intermediate seams between sheets of plywood can be wiped with putty and left to dry. Then drying oil is applied to the dried sheets and the surface is again dried.

On the resulting perfectly flat surface, you can lay linoleum. Stripes are cut to the size of the room + 10cm. If linoleum has a complex pattern that requires adjustment, then the margin for cutting should be + 1 pattern. The stripes are laid out starting from the middle of the room and smooth them to the walls. It is best to let them lie down for at least a day after laying the strips. Then the linoleum will lie flat, and will not warp and swell. At the edges of the room, linoleum is fixed with skirting boards, and the seams between the strips are glued with cold welding.

How to lay linoleum with your own hands on a concrete floor

Laying linoleum on concrete floors can be done in two ways.

Flooring on a concrete base implies leveling the surface with a screed on which the waterproofing film is laid. A heater is placed on top of the film that can withstand the daily direct load and only then linoleum strips roll out.

To make a perfectly flat floor under linoleum, you can use the arrangement of the lag system.

The recommended size of the bars for the log is 40 * 100. Length may vary depending on the size of the room. When buying, you should immediately pay attention to the quality of drying the bars should have a transport humidity of 18-22% and no less. When wood has a moisture content of more than 30%, intercellular moisture is stored in it, which can lead to decay of the product, as well as to curvature and warping.

Waterproofing is the basis of work with any floor covering, so first polyethylene is laid on concrete. Logs are mounted on the floor in increments of 0.7-1 m, although you can be guided by the width of the insulation and choose the width of the gaps between the bars based on the standard sizes of heat-insulating materials. The level when installing the lag, you must use it!

Next, lay the insulation in the gaps, and you need to make sure that the material does not compress too much when laying, this significantly reduces its heat-insulating properties.

On top of the lag system, lay the sheets of multilayer plywood and carefully screw them to the structure.

Spread linoleum strips, starting work from the middle and spreading the coating to the walls. Allow material to lie down so that it is properly straightened. Fix the edges with skirting boards and apply cold welding to the joint seams. That's all. Do-it-yourself laying linoleum on the floor is done brilliantly!