Search

Login

Recommended

Plastic panels for decorating the bathroom, choosing the right one, useful tips

If there was a desire to make a beautiful repair in the bathroom, but at the moment there is no way to spend a lot of money on it, and sometimes even time, then it is quite possible to resort to plastic walls and ceilings on the walls. They look attractive, have sufficient resistance to high temperatures and moisture.

Content

- How to choose plastic panels for the bathroom video

- Plastic panels for the bathroom - types of material

- Finishing the bath with plastic panels - the pros and cons

- Finishing the bath with plastic panels - where to start work

- Frameless mounting method

- Ceiling in the bathroom from plastic panels

How to choose plastic panels for the bathroom

Any finishing material requires special attention to your choice. Especially if it is widely represented in a network of construction stores. For example, our favorite plastic panels from different manufacturers can differ significantly in shades, sizes, thickness and density of plastic.

First of all, when choosing a material, we pay attention to the evenness of its surface. In no case, wavy transitions should not be visible on it - the walls lined with such panels will not have an attractive appearance.

Next, we study the strength properties - is it possible to pierce it with a sharp object, we determine whether the panel will break under bending stress. When buying, pay attention that all the material is from one batch, otherwise it is unlikely that you will be able to avoid some difference in the saturation of the shade.

Plastic panels for the bathroom - types of material

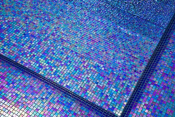

The panels on sale differ in the appearance of the coating, they can be glossy or matte, the method of applying a picture to their surface can be printed or film. The printed drawing is applied to the plastic with paint, the film - the paint is applied to the film, which is glued to the panel. The panels also differ in the type of joining - when installing the first tiles they fit very tightly, seams do not form, when installing others - the presence of seams is mandatory, they are provided for by decor.

Finishing the bath with plastic panels - the pros and cons

The positive qualities of the material include:

- installation that can be done independently

- undemanding coating for special care,

- the relative cheapness of the material,

- moisture resistance

- preparation of walls for installation work is not required,

- the ability to cover all kinds of flaws on the walls under the panels,

- easy to hide wiring and various communication structures under the panels.

Among the important disadvantages of the material can be noted:

- relative fragility, requiring careful treatment,

- insufficient level of environmental friendliness.

Finishing the bath with plastic panels - where to start work

Since most of the bathrooms in houses built not so long ago are very small, it becomes necessary to save every square centimeter of space. In order not to take away from the bathroom area these valuable centimeters, it is best to start work by ridding the walls of a layer of old plaster. Although its thickness is negligible, but to some extent it compensates for the cost of usable space for installing the frame. Since sand-lime plaster was usually used in old houses, it will be quite simple to remove. The only thing required is to think about dust protection. You can wear a respirator, or use a regular gauze bandage. It is better to curtain the doors to the bathroom with a thick cloth or plastic wrap. You will also need to cover the furniture in the bathroom and other rooms with plastic wrap.

The advantage that we get from installing plastic panels on the frame is the ability to hide all communications under them: pipes and wiring. At the stage of repair planning, one should think over the lighting option, analyze the need to replace metal pipes with plastic ones, and replace plumbing.

Replacing pipes - most likely it will be necessary - it is dangerous to leave old pipes, they can leak at any time, it is doubly dangerous that they will be hidden under plastic panels, in this case it may not immediately leak. For the installation of new communications use ecoplast or metal plastic. It is advisable to install new pipes as close to the walls as possible - in this case, you can get some savings in useful area costs by maximizing the frame to the wall.

Before starting the installation of the frame, you should determine the points at which you need to output the wires. Fasten the sockets on the plastic panel should be the same as on the drywall surface. A hole is cut out in the panel, then it is attached to the wall.

frame mounting

Then you can proceed directly to the installation of the frame. To begin with, we recall that it can be wooden or metal. If you choose the option with a wooden frame, you must first mark the vertical lines along which the rails will be mounted. The distance between them should not exceed 0.4 m. With less - the wall will be easy to push through. Then we fix the brackets along the lines, the distance between which is 0.5-0.6 m. A vertical rail of 50x20 mm is attached, strictly vertically, in level. For fastening the rails to the brackets, 25 mm screws can be used.

If preference is given to the option with metal, then you can use the CD profile used in the installation of drywall. Further, everything is done in the same way as when installing wooden battens. To fasten the profile to the brackets, you can use small screws. When installing the last profile or rail, it will not be possible to screw them from the side of the side wall. Therefore, the mounting is carried out with an accessible, with one that is not available, the bracket bends at the top of the profile and is mounted on the front side.

You can install panels on both types of frame, but remember that metal is not afraid of moisture and will last longer.

plastic panel finishing - installation

After assembling the frame, they begin to install panels on it. For fastening, 25 mm screws are used, depending on the material of the frame - for metal or wood. To cover the hats of the screws, pads are used, a little sealant can be applied to their inner side for high-quality fastening. Silicone sealant is also used to seal all joints.

Do not forget that plastic can deform when exposed to high temperatures, therefore, under the radiators or dryers in the bathroom, a heat reflector is substituted.

how to make corner joints

The greatest difficulty is the processing of corner joints. To give them a neat appearance, you can use the corner profiles internal and external, which are used when assembling the lining. There is no point in inserting the lower part into such a profile - the baseboard will close it.

Frameless mounting method

There is another embodiment of the installation work that does not require the construction of the frame. It involves sticking plastic panels directly onto the wall surface. Among the positive aspects, we can mention the fact that the plastic glued to the wall does not take up useful space, even with careless handling it will be more difficult to push. But if you need to perform the dismantling of the finish, then difficulties may arise. While the use of self-tapping screws will make it possible to disassemble the finish of the entire bathroom in a matter of hours.

Fastening panels to glue is simple and quick, and you don’t need to spend extra money on the material for the frame and time on its construction. The preparation of the wall surface will consist in its cleaning, disinfection, leveling and priming. Then you can proceed with the installation work. If the walls of the bathroom are far from perfect in terms of alignment, then the glue method of fixing plastic panels in it is better not to apply. Panels can only be glued on walls that have no bulges, even small diameters, and surface drops should not be larger than 3 mm, while small hollows are allowed.

Liquid nails can be used as glue; their consumption depends on the state of the surface of the walls in the bathroom. On average, 5 sq.m. the wall will require approximately 1 cylinder of glue.

Glue on the surface of the panel should be applied pointwise, but not too close to the edges - in the process of pressing the material against the wall, it can come out and smudge the front side. The panel with the adhesive applied is pressed against the wall for several minutes, pressed down, dried.

Particular attention will need to be paid to the first of the strips to be glued - it is leveled to the level, fastened from above and below by dowels, which will later be hidden under the ceiling and floor skirtings.

Ceiling in the bathroom from plastic panels

The construction in the bathroom of a ceiling made of plastic panels is one of the most acceptable options - the advantages of such a ceiling coating significantly exceed its disadvantages. It will serve for a long time, without requiring any special care, operation in high humidity conditions will not threaten it with the loss of an attractive appearance or a change in parameters.

Plastic ceilings in the bathroom, the price of which is quite low, are also attracted by the ease of installation, undemanding to the surface on which they will be mounted. The panels are interconnected hermetically, they do not allow moisture to pass through, so the option of mold formation under the panels is practically eliminated.

Under the ceiling structure made of plastic panels, it is easy to hide the wiring, and its design will allow you to create a multi-level surface.