Search

Login

Recommended

Kamenka stoves for a Russian bath, furnace designs. Do-it-yourself stove for a Russian bath

Can a Russian bath exist without a stove? Of course, no - in this case it will turn into a completely uninteresting and prosaic bathhouse, because the main thing in a Russian bathhouse is steam. To obtain it in the required quantities and is built in the sauna stove. It heats the air in the steam room to a temperature higher than 60 degrees, on its hot stones it accumulates thermal energy, the water falling on the stones is instantly transformed into such a healthy steam that burns steam.

Content

- Basic requirements for stoves

- Types of stoves, stoves with closed stove and open

- Basic principles for the construction of a stove

- DIY stove heater video video

- Stove heater order

- Two types of stoves video

- How to choose a stove-heater for your bath

Basic requirements for stoves

Because the stove represents the most important component of the Russian bath, serious demands are made on it:

- high heat output, the ability to heat air to a temperature of 95C under the ceiling of the room (on the floor - up to + 45 * C), raise the temperature to the desired parameters in a short period of time, while being economical

- it should not take up much space

- the volume of heated water should correspond to the minimum requirements of all family members, which is about 15 liters per person

- its design must be such that the heat accumulated by the stones is retained for a long time

- when the stove is in operation, gases and smoke should not enter the room.

Types of stoves, stoves with closed stove and open

To obtain steam, they resort to pouring water on hot stones located in a stove-heater. Thus, the stove heater heats the entire room and creates the required microclimate in it.

There are two types of stove-stoves for a bath: a stove with a closed stove or an open one. For small baths, you can use an open type oven. It allows you to heat the room very quickly, but after watering the stove quickly cools. Stones in this model are placed above the firebox.

Most often, a stove-heater for a bathhouse is constructed of a closed type, in them the fuel is burned with the steam door closed, it is at the same level as the upper row of stones. To accelerate the heating of the bath room, they resort to opening the door. Such a furnace should be melted well in advance - it will take a couple of hours to warm up. Heat is stored in closed heaters for a couple of days.

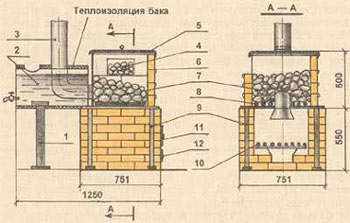

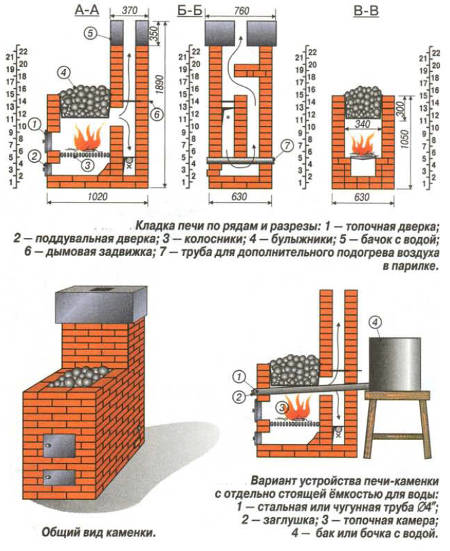

Brick oven with a metal heater and a lateral location of the water tank: 1 - tank support; 2 - a tank for water; 3 - chimney; 4 - hatch for watering stones; 5 - heater cover; 6 - wire clips; 7 - stones; 8 - heater grill; 9 - rack pedestal heater; 10 - grate; 11 - firebox door; 12 - blower door

To heat the bath and get steam in it, brick and metal structures are usually used. They are heat-resistant, simple, reliable in operation. Brickwork prevents too much heating of the metal structure, bath stones can heat up below - up to about 1000 degrees C, above - up to 500.

Drawings of the stove-heater can be various, depending on the design and the estimated mass of the structure, the project may include the construction of the foundation - with a design weight of the stove over 450 kg, or without it - with less weight.

Experts recommend deepening the foundation by 0.5 m relative to the soil surface, in each direction it should be 0.1 m wider than the base of the stove. For the manufacture of the foundation, you can use concrete or rubble stone. It will also not be superfluous to lay a layer of waterproofing material - glassine or roofing material on a series of bricks laid on top of the foundation foundation.

Basic principles for the construction of a stove

To prevent the occurrence of fire hazard situations, it is not recommended to violate the following rules.

- The stove should not be built closer than at a distance of 0.4 m from those made of wood or other fire hazardous materials; for metal stoves fired with bricks, it is recommended to increase this distance to 0.7 m, for metal stoves to 1 m. If the room is small, then to reduce the distances, you can resort to wall insulation with asbestos board and foil.

- For the construction of a stove-heater, only red brick of normal firing is used, without defects, with straight edges.

- It is not recommended to use a brick made with violations of firing technology (burnt or unburnt), silicate brick, slotted and perforated - they all quickly collapse under the influence of high temperatures.

DIY stove heater

When building a stove-stove with their own hands, they use a solution made of sand and clay. Plaster, if it is supposed, is made with a solution of clay, sand and lime, which are mixed in a ratio of 1: 4: 1. Sand should be used in good quality, free from impurities. dry, before preparing the solution it is sieved. Do not use fine or silty sand.

The clay is soaked before use, for which it is poured into a metal container and poured with water. It is best to use clay, which was outdoors in winter and underwent a freezing process. The proportions of the mixed sand and clay may vary somewhat depending on the quality of the clay.

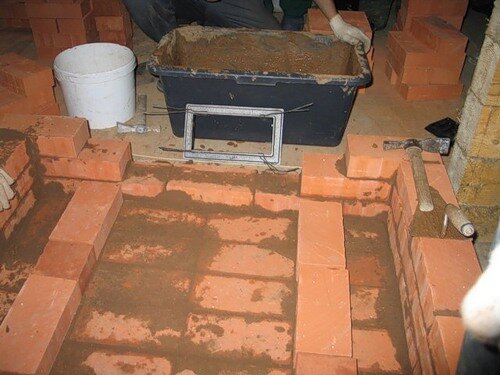

Brickwork begins from the base.

Before laying, each brick should be dipped in water for 20 seconds - this time will be enough to fill its pores with water. Laying the foundation of the furnace to the floor level is carried out on a solution of cement and sand, having a ratio of 1: 3. Next, a clay sand solution is used. Before laying the base of the furnace, another layer of waterproofing is arranged.

When laying a brick, it is recommended to carefully compare its dimensions in height and length, usually for high-quality masonry it is enough to lay each row dry. The seams in this order of work will turn out beautiful and of the same thickness, it is recommended not more than 0.5 cm. The rows begin with a corner brick.

When performing masonry, it should be strictly monitored so that the rows are laid strictly horizontally, the seams between the bricks must be very tightly filled. The verticality of the masonry is determined using a plumb line, the horizontalness is determined using a level. When laying brick, avoid combining vertical joints, each of them should overlap in a subsequent row.

In the process of masonry, such indispensable components of the stove-heater are mounted as: grates, damper, doors, water tank. The grate of grates is installed in the furnace opening, taking into account a gap on all sides of about 0.5 cm. For blowing and furnace doors, pieces of wire with a diameter of 2 mm are laid in the seams. Laying in rows with a door begins from the place where it is located.

When installing a tank, a stove-heater with a tank suggests filling the space around it with a clay-asbestos mixture, which will allow the tank to expand freely when heated.

If this moment is not taken into account, then there will be a threat of cracking in the masonry.

In places where the chimney passes through the ceiling and roof, a layer of thermal insulation is necessarily laid, for example, mineral wool covered with foil or tin. To protect the chimney from rainfall, a tin hood is constructed above it.

Immediately start operating the stove in the bath is not recommended - it should be thoroughly dried. This may take 3-4 days. All doors and dampers must be open when drying. Windows and doors are also left open.

First, the stove-heater is heated with slivers for 15 minutes several times a day. Repeat the procedure until no moisture appears on the surface of the shutter. This is a clear sign that the stove is completely dry. You should not rush to the start of operation of a large furnace - its strong heating can disable it.

Since for the construction of a stove-heater they usually use high-quality bricks with a rather decorative look, it is not necessary to plaster it. In addition, the brick looks good enough against the background of walls made of natural wood.

Stove heater order

So that the stove can cope with the functions assigned to it during its laying, it is desirable to use a special scheme on which each row is displayed in a cross section.

For different types of stoves, a strictly defined number of rows is provided, their number depends on the size of the structure.

Ordering example:

Reducing their number is permissible only if the ceilings in the room are very low.

Two types of stoves

There are two types of wood-burning stoves: periodic and continuous. Batch ovens are not heated during a steam room visit, but several hours before people arrive, for 3-5 hours. During this time, the stones manage to reach a temperature of about 900C. Steam in saunas with such stoves is dry and light; it does not burn the body. It is impossible to heat such a stove with visitors - the smoke from it enters the steam room.

Continuous furnaces, on the contrary, suggest their heating during the adoption of procedures. Stones in such models are placed in metal containers, their heating temperature can reach 600C. Steam in such baths is raw and burning.

How to choose a stove-heater for your bath

Since the requirements for the furnace are quite diverse and somewhat contradictory, the choice of the type and size of the furnace should be treated with special attention. First of all, the design should correspond to the dimensions of the room. If its sizes are from 4 to 9 square meters, then the best option would be a metal stove lined with bricks. It is relatively light and is built without foundation. But at the same time, it will require reinforcing the floor at its location with thickened plah boards. For a more even distribution of the load, a sheet of asbestos board and metal, about 2-3 mm thick, is laid under its base.

The stones for the steam room itself should also be carefully selected. They have to:

- have a large specific gravity and a dense structure, a uniform surface, do not crack when water enters them,

- be environmentally friendly, do not contain chemical or radioactive impurities harmful to humans,

- be heat resistant

- their dimensions should correspond to the recommended range: 70-130 mm for large and 50-60 mm for small samples.

It is best to purchase stones for a stove-heater in specialized stores.