Search

Login

Recommended

Features of sectional garage doors, do-it-yourself sectional door installation

The design of sectional doors was developed about 40 years ago in Germany. Today it is the most common type of garage door in Europe. In Russia, sectional doors are just starting to gain popularity among consumers.

Sectional garage doors have a wide scope. They are installed at industrial facilities, in car services, car dealerships and parking lots. The gates installed in private houses and underground garages perfectly emphasize and complement the architecture of the building.

Content

- The principle of operation and design features of sectional doors

- Advantages and disadvantages of sectional garage doors

- Which is better: to make sectional doors yourself or trust professionals? video

- Installation of sectional garage doors

- The main criteria for choosing a sectional door video

The principle of operation and design features of sectional doors

Sectional doors are a lifting mechanism, during operation of which a flexible sheet rises and retracts under the ceiling.

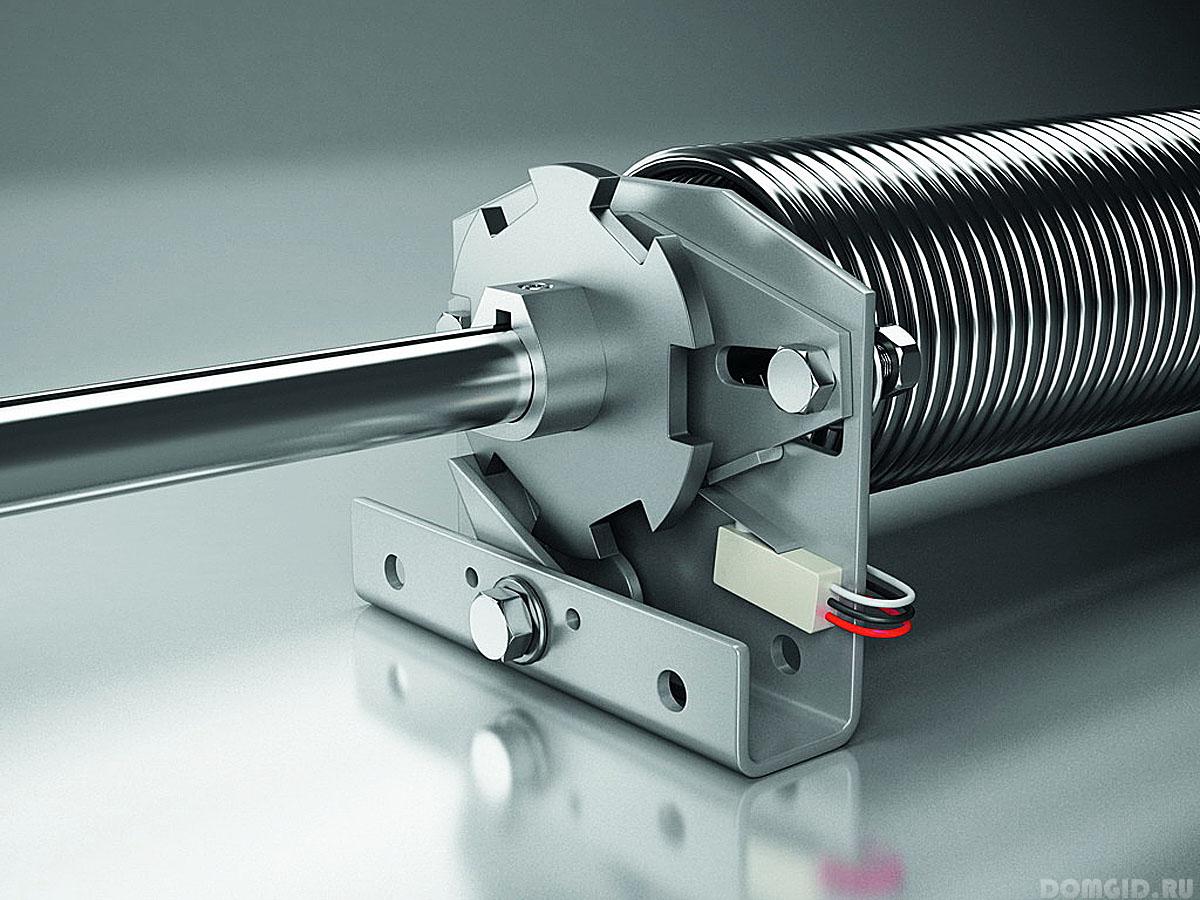

The canvas consists of four to six sections, interconnected by hinge loops. When the gate opens, the sections slide up and fold onto each other. The movement is due to the drums and cables balanced by a spring mechanism. Along the frame and under the ceiling are guides along which the panels slide on the rollers.

The standard sizes of sectional doors for garages are:

- height 2-6 meters;

- length up to 5 meters (gates up to 7 meters can be made to order);

- width of one section (35-61 cm).

It is advisable to install a gate with the minimum required dimensions. Compact gates work more stably, reduces the risk of blocking the gates (heavy modules can jam in the guide grooves)

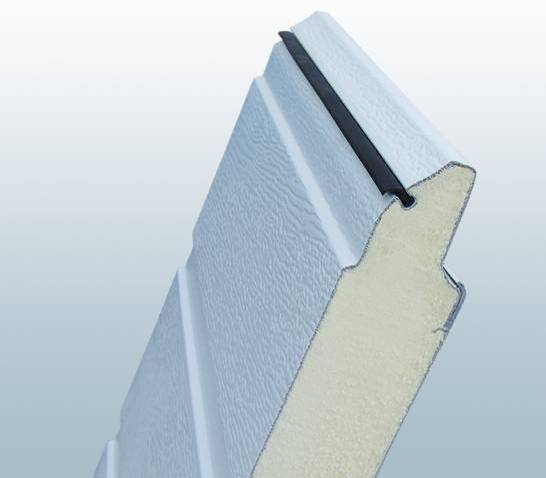

Each module is made according to the principle of sandwich panels. The outer sheets are made of aluminum or galvanized steel. To make the sections decorative, they can be covered with a wooden panel, which significantly increases the cost of the gate.

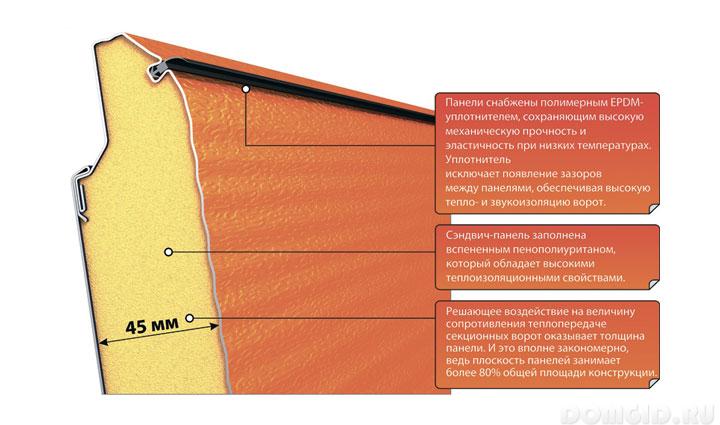

Depending on whether the room is heated or not, the thickness of the sandwich panels is selected:

- 20 mm cold canvas is suitable for an unheated garage;

- 35-45 mm insulated sections (thermal insulation properties are equivalent to brickwork of one and a half bricks).

The internal filling of the modules is a non-absorbent insulation (polyester or polyurethane foam). Cork material is installed between the gate sections, which ensures a tight fit of the modules to each other and prevents the occurrence of cold bridges (the permissible gap size is not more than 4 mm).

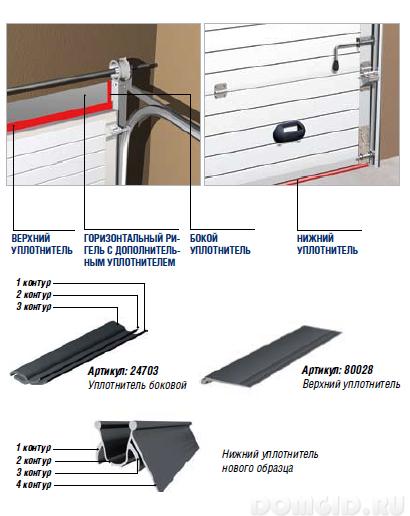

The lower door panel is equipped with an elastic seal, so that the metal section does not freeze to the floor in cold weather.

The automatic sectional garage doors are equipped with an electric drive with the possibility of manual control when the power is cut off. The electric motor is mounted on the middle rail, which regulates the movement of the wings.

Advantages and disadvantages of sectional garage doors

Sectional doors have many advantages:

- saving space in the garage and at the entrance to it;

- high thermal insulation with sections from sandwich panels (coefficient of thermal conductivity 0.5 W / sq.m);

- good soundproofing of sandwich panels (29 dB);

- reliable sealing of the opening;

- universality of use (gates can be installed in rooms with different opening lengths);

- fireproof design (materials used prevent the spread of fire);

- ease of use;

- decorative and aesthetics (any pattern can be applied to modular sections);

- long warranty period (about 10 years);

- ease of repair (if the door breaks, it is enough to replace one damaged section);

- control can be manual, remote and automatic;

- safety of use (modern sectional doors are equipped with a cable break protection option).

The disadvantages of sectional garage doors include their high cost and the need for periodic maintenance. If the gate is installed correctly, then repairs will not be needed soon. Typically, his need arises when sectional modules are damaged by motor vehicles or spare parts are worn out (rollers, balancing springs, moving parts of the mechanism).

Which is better: to make sectional doors yourself or trust professionals?

The desire to minimize waste and realize creative potential is pushing many motorists to design and manufacture sectional garage doors with their own hands. However, the result does not always live up to the efforts and expectations.

Very often, the complexity of self-taught designs increases costs, and the finished product cannot boast of high reliability and durability. Factory models have special safety features that prevent accidental web drops.

It is advisable to independently assemble the gate according to the original drawings, using cheaper factory parts. As an option, you can buy used mechanisms in good condition by well-known and reliable manufacturers.

The main thing in self-assembly is to read the layout scheme of sectional door construction details correctly

If there is no particular desire and extra time to experiment, then the best option is to buy ready-made gates and install them by representatives of the manufacturer.

Among domestic firms, a large holding of Dorkhan companies has proven itself well. Sectional garage doors Dorkhan are divided into two types:

- gates with tension springs can be installed with the minimum requirements of the lintel, but they are noisier and are designed for fewer work cycles;

- gates with a torsion mechanism are considered the most reliable and practical (designed for 25,000 work cycles), have a higher price.

Dorhan garage door panels have a thickness of 40 mm, filler polyurethane foam, the outer layers are galvanized steel with polymers.

In the construction of parking lots and cottages, Alutech sectional garage doors are widely used, which have high strength and safety indicators.

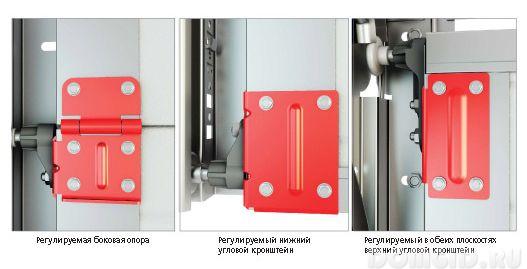

The thickness of the sandwich panels of Alutech doors is 45 mm, the filler is foamed polyurethane, the outer layers are steel 0.4 mm thick with a zinc coating of 16 microns. The elasticity and mechanical strength of the modular sections is achieved through the polymer EPDM-seal, which are equipped with door panels.

Alutech sectional doors are warm and hermetic, which allows them to be used in any region (even in the frosty conditions of the Far North).

Installation of sectional garage doors

Necessary tools and materials

For self-installation of sectional doors, you need to purchase all components and prepare the necessary tools.

Sectional door mounting kit includes:

- sandwich panels;

- guides;

- torsion gear;

- additional accessories and components.

For work you will need:

- pliers;

- spanners;

- hammer;

- riveting gun;

- drill with a set of drills;

- roulette and level;

- hand gloves and safety glasses;

- drill with a perforator;

- construction knife and pencil.

Doorway preparation

Before starting the installation of a sectional garage door, it is necessary to prepare the room and the doorway:

- Take measurements of the width of the opening at three points (top, middle and bottom). The greatest value is taken as a basis.

- Adjust the horizontal position of the floor.

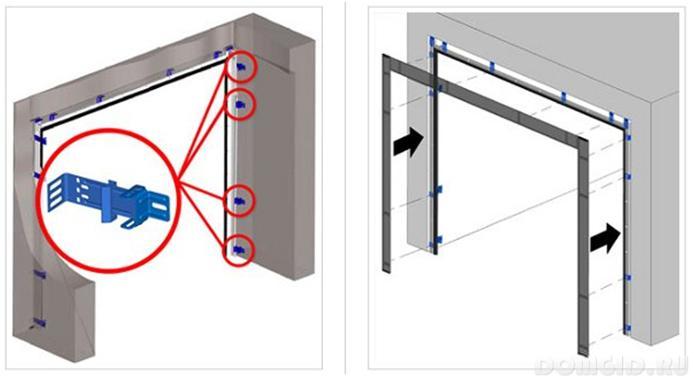

- The shoulders and lintel must be in exactly the same plane.

- The minimum gate depth must be calculated as follows:

- door height + 50 cm (for ordinary sectional doors);

- door height + 100 cm (for doors with a drive).

- The ceiling and shoulders should be made of durable material (reinforced with a metal frame), since they will bear the main load when opening / closing the gate.

- The optimal size of the lintel is 25-50 cm, the shoulders about 45 cm.

- Before installing the gate, the opening must be plastered.

Permissible horizontal error of the floor in the garage is not more than 0.1 cm

Installation work: rules and installation procedure

Proceeding directly to the installation of sectional garage doors, it is necessary to take into account some important points:

- The basic rule of competent installation is the observance of a clear vertical doorway and tight fixation of all structural elements. Sectional doors will not tolerate distortions.

- In the work it is necessary to use self-tapping screws, dowels and anchors, of the sizes indicated in the instructions.

- Do not use foam or wooden pegs to level the structure. Adjustment of the door can be done with different-sized metal linings.

The order of assembly and installation of sectional doors:

- Transfer the gate scheme (available in the instructions) to the gate opening. Mark the attachment points of the profiles (horizontal and vertical).

- Align and lock the vertical opening.

- The fastening of the supporting parts must begin with the bottom lamella, clearly following the instructions.

- Assembly of the web, starting from the bottom sectional panel.

- The upper sash of the canvas should fit snugly against the strips. This can be achieved by adjusting the upper brackets.

- Fastening of control mechanisms, locks, bolts and handles.

- Installation of balancing springs. Lifting cables must be tight.

- Fastening and connection of the electric drive for automatic sectional doors.

- Setting the web limiter.

- Checking the course of the canvas (opening and closing the gate).

If the work is performed not alone, but in the company of one or two more voluntary assistants, then it will be possible to complete the installation within two to three hours.

The main criteria for choosing a sectional door

In order for the operation of sectional doors to be long and uninterrupted, when buying a product, you need to pay attention to some important parameters.

- Packaging quality and accompanying information. The product must be delivered with a passport and a certificate of quality. The door panels must have multilayer packaging made of corrugated cardboard, and the fittings and structural units should be delivered in boxes protected from moisture.

- Panel painting quality and galvanizing thickness. The metal should not be visible, otherwise corrosion processes will soon begin.

- The thickness of the sandwich panels. This parameter determines the thermal insulation properties of sectional doors. For reliable protection of the room from frost, you need to choose panels with a width of 45-50 mm.

- Seal and Pads Material. Elastic pads on the sash sectional doors prevent the appearance of drafts. Roller brackets must have control systems that will ensure that the panels adjoin tightly to the strips.

- Garage door. A built-in gate increases the cost of the gate by one third. It is desirable that the door has reinforced edging profiles, a linear closer and a motion sensor.

- Operation cycles.For private use, household garage doors designed for 25 thousand cycles are suitable; for production needs, installation of gates for 70-100 thousand cycles will be required.

Sectional doors have many advantages and are often used in the construction of a garage. With the right choice and proper installation, such gates will last a long time, without requiring costly overhaul.