Search

Login

Recommended

DIY smokestack installation

In any construction and installation of chimneys, i.e. where there is a conclusion of the chimney and (or) ventilation pipe through the roof of the building, the question arises of preventing leaks at the point of contact of the pipe and the roof.

Content

- General informationvideo

- Apron on the roof

- Joint sealing at round pipe outlet

- What is Master Flash

- Features of the installation of chimneys

- useful tips

General information

When installing a chimney, it is necessary to achieve full confidence in the safety of the structure and the implementation of the rules for the operation of chimneys.

With a large bookmark of firewood and a completely open shutter, it is possible to warm up both the stove and the pipe itself. Now there are many products that protect your building from fire.

These are protective shields, and sandwich pipes, metal chimneys.

Apron on the roof

The folded roof is considered one of the most reliable, because the double folding lock completely eliminates the possibility of leaks, and the smooth metal surface provides a good drain of water.

But the same lock is the main problem when removing the pipe through such a roof. The lock protrudes above the surface of the roof and greatly interferes with the installation of the apron.

Experienced stovemen offer this method: around the perimeter of the proposed apron, they lay on the roof a wooden frame of boards with a thickness equal to the height of this seam i.e. just the frame is attached to the roof battens through the iron using self-tapping screws.

Next, a metal apron is placed on a wooden frame. In order to prevent water from flowing under an apron during oblique rain, the metal bends towards the roof.

If the ridge of the roof is decorated separately from galvanizing, then we fill the upper part of the apron under a slice of this strip and nail the apron to the frame.

If the ridge is designed without such a strip, then we bend the apron on the opposite side of the pitched roof, i.e. when cutting an apron, an allowance of 20-30 cm is necessary. And the manufacture of a wooden frame for part of the apron on the second ramp.

Installation of such an apron, although it will take longer than with the traditional method, but the joining of the roof and the chimney will be reliable, and the whole structure will look more accurate. A chimney hood is always placed on the chimney itself.

Joint sealing at round pipe outlet

The advent of modern roofing materials has not eliminated the use of a metal apron for sealing chimneys, but the apron is not very suitable for sealing round pipes, problems begin when using asbestos-cement or iron pipes.

Previously, cement mortar was most often taken to seal an asbestos-cement pipe on a slate roof, because it adheres well to slate.

With round iron pipes it was even more difficult: the solution on them does not hold well, and sealants melted due to the high temperature.

It was necessary to put a frame of asbestos-cement sheets at the exit of a round pipe, then they filled the box with a solution, and only then they sealed it with an apron.

Now the requirement for quality and appearance has become more stringent and here Western manufacturers are helping us.

What is Master Flash

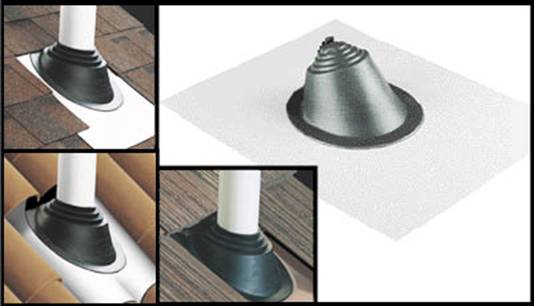

For sealing metal pipes universal sealants of roof passages Master Flash are used.

They can be used for all types of roofs, including corrugated.

These universal rubber seals withstand temperatures from + 135 to - 55 degrees and at the same time do not lose their elasticity, tightness and elasticity; they are attached to the roof base with screws.

You can buy Master Flash in specialized stores.

Features of the installation of chimneys

butchering and retreat

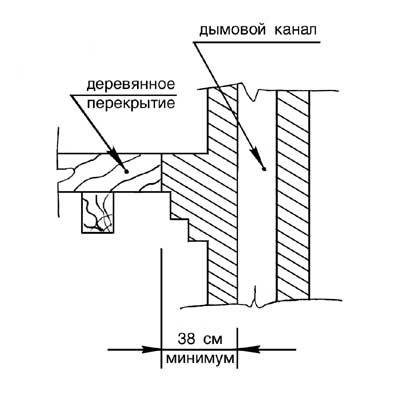

Since constant monitoring of pipe operability is difficult, therefore, full confidence in fire safety should be achieved. SNiP2.04.05-91 prescribes the need to maintain a distance of at least 500 mm from smoke to any structures of combustible materials.

This distance is called cutting, i.e. this is a non-combustible space between the fire or smoke in the stove (smoke channel) and the building itself in which the stove is located.

In brick ovens, cutting is done from the same brick from which the furnace and pipe are folded.

When a furnace is installed, the opening in the floor and ceiling becomes wider than the width of the furnace. The gaps between the furnace and the opening are laid with a brick, this is the cutting.

If the gap is not bricked up, then this is called a retreat.

When the pipe passes through the ceiling, it turns out that the opening is larger than the pipe section, the walls of the brick pipe thicken, this is also cutting. Conclusion: butchering is a non-combustible part of the furnace adjacent to the structure of the house. Cutting is not necessarily made of brick, it can be made of concrete, asbestos cement, i.e. from any non-combustible material.

thermal protection of metal pipes

Modern requirements for the dimensions of the indentation and cutting are softer, allowing a reduction in the size of cutting to 380 mm., Protecting adjacent combustible structures with metal sheet on asbestos cardboard.

A metal pipe in a red-hot state is a very serious fire hazard, it must be protected with non-combustible materials (asbestos board or cord) or a sandwich seal.

what is a metal screen

A very good solution to this problem is a metal screen with an insulation layer of mineral heat-resistant basalt wool, 10-20 mm thick., In this case, the distance from the outer surface of the pipe, i.e. from this screen to combustible elements of the roof can be reduced to 130 mm. in case of emergency.

free running of the pipe under thermal stress

Important! Glass wool for pipes cannot be used, the pipe should be able to expand and lengthen due to heating, to move freely in the holes of cutting sheets.

This must be taken into account when manufacturing the screen, so it does not need to be firmly fastened to the pipe (at least one of its ends), since the screen heats up less than the pipe.

On the roof, the joints of the pipe and cutting sheets are sealed with non-combustible heat-resistant sealants, or simply wrapped with asbestos cord soaked in a clay-sand mortar, coated with a cement-sand mortar.

Due to the thermal expansion of the pipe, the tightness of the gaps is broken, so flanging of metal sheets or corners is used to protect against leaks.

Since, in terms of leaks, the joint of a hot pipe with cold roofing material is an extremely unreliable element, therefore, shielded heat-insulated pipes are preferable in all respects.

Very good designs are produced by Finnish manufacturing companies. But even, for this reliable design, cutting is required, at least 380 mm. from the wall of the chimney.

Useful Tips

A positive aspect of the Finnish design is the fact that the pipe does not rest on the roof, but on the stove, and this also ensures greater safety. This design of the chimney can be made independently. First, the frame of the shielding pipe is welded from the corners, then sheathe it with sheets of galvanized steel.

With steep roofs, it is necessary to protect the pipe from avalanches. To do this, put metal dividers, reinforce stretch marks. It is necessary to make a ladder for climbing the roof, for periodic cleaning of the pipe

To prevent soot fire in the chimney and chimney, especially if the furnace is fired with firewood giving thick black smoke from the chimney, it is necessary to periodically clean the chimneys and chimney.

In the bath, the chimney from the surface of the furnace to the ceiling is often not insulated and not shielded, since the hot pipe provides infrared radiation, this is important for initial heating and you do not want to refuse it. In this case, it is necessary to increase the deviation from combustible structures and provide additional protection against emergency burnt pipes.

Sometimes, on this bare pipe section, to increase heat transfer, fin-radiators are additionally installed. This cannot be done, since dust is collected here that can ignite.

Infrared radiation is of great importance in the processes of heating black baths. Due to this radiation, all lower elements and distant walls are well warmed up. Therefore, infrared radiation in a black bath is very, very desirable, especially since there is no harmful effect from this radiation.