Search

Login

Frame partitions

Modern construction technology greatly reduces the construction process, making it simpler and easier, allowing you to do a lot with your own hands. Partitions with a metal frame are quickly erected, they can radically change the design of the room, and they cost an inexpensive host. With proper, correctly executed work, these designs guarantee acoustic and fire protection.

Content

- Advantages of installing a drywall partition

- Techniques for Proper Installation video

- Installation Tools

- Materials

- Working process

- Installation of double partitions, design features

Advantages of installing a drywall partition

The use of frame partitions equipped with fireproof soundproofing is very convenient in terms of lightening the weight of the building. But, despite the low weight, such partitions provide even better sound insulation performance than the massive wall of the same thickness used in construction in previous years.

It is necessary to take into account the minimum labor costs, with modern technologies, many construction issues are solved in the family circle, the minimum construction team consisting of husband and wife, easily solves many issues on their own.

This also applies to the construction of the frame partition. Initially, it is important to choose the right wall structure.

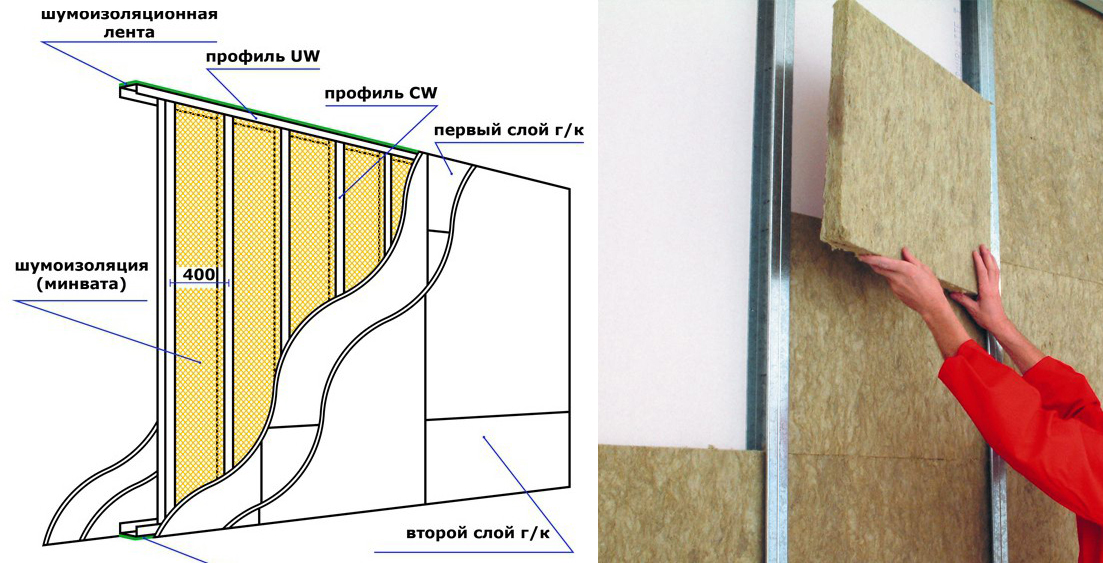

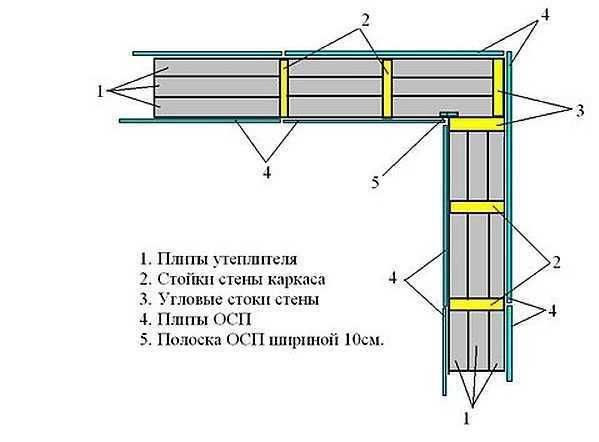

It is very successful to choose the option of installing rack profiles with a staggered shift, the result of this is the ability to fasten the skin on one side with respect to the second side, with a shift by a span between the racks. The use of installation of profiles in a checkerboard pattern leads to very high rates in sound insulation. Thus, the so-called sound bridge in the wall is isolated.

Techniques for Proper Installation

The following conditions must be observed:

- wall cavities (air space between the walls of the partition) must be completely filled with sound-absorbing material. It is good to use mineral wool as a sound-absorbing material, since this material is non-combustible;

- a combination of non-combustible mineral wool with the same non-combustible gypsum boards, are the best way to protect in case of fire, from the rapid spread of fire;

- for better acoustic effect and improved fire protection, two-layer casing can be used;

- it is very important, when installing the frame partitions, to correctly mount the side junctions, therefore, under the frame profiles, in the places where they are attached to the main walls, it is necessary to lay soft material;

- Of course, it is optimal when isolation is provided in all side walls and floors of the floor and ceiling using a dividing seam.

Installation Tools

- a hacksaw, metal scissors for profile cutting or a grinder;

- water level and plumb;

- drill and cordless screwdriver;

- hammer, metal ruler, knife, square;

- jigsaw;

- drachovy file, for rough processing of drywall plates, putty knife.

Materials

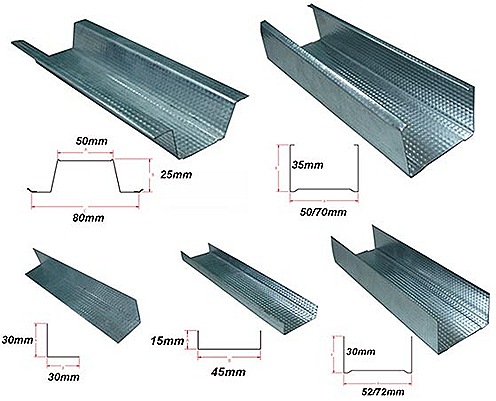

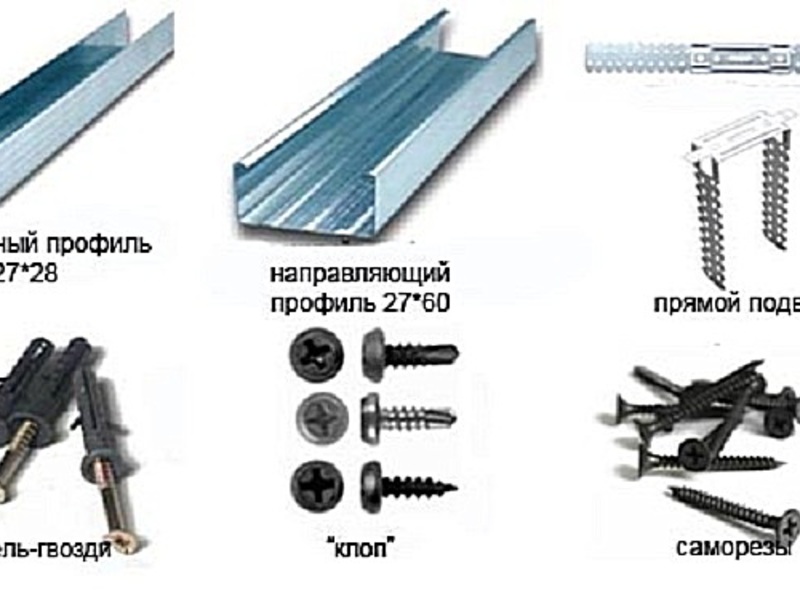

1. Profiles for the assembly of the frame.

2. Gypsum boards, at least 12.5 mm thick.

3. Sound and heat-insulating material for laying in the partition.

4. Felt or mineral wool strips, for lining under frame profiles.

5. Self-adhesive sealing tape.

6. Self-tapping screws for fastening to a metal frame.

7. Screws, screws and dowels.

8. Putty for seams, adhesive tape, a cylinder of acrylic sealant.

9. If necessary, a jumper for the door frame.

Working process

1. Mark with the help of a wide masking tape the location of the future partition. Marking with a wide masking tape will be clearly visible and will protect the floor and ceiling from traces of acrylic sealant.

2. To prevent the propagation of sound (the appearance of sound bridges), in the places where the walls adjoin, if a dividing seam is not provided, a groove is formed on the wall with a continuous sheath, for which, if this wall is sheathed with drywall, a drywall sheet is cut and a strip is removed a little less vertically width than at the end of the erected partition. Remember, before installing the partition, at the junction with the main wall, it is necessary to dig a vertical groove, thinner than the partition wall.

3. The same must be done at the place where the partition closes the ceiling. This work can be done using the router, limiting the depth of cut. Care must be taken not to disturb the vapor barrier film located under the ceiling sheathing. Attached in advance rail, will serve for the milling guide.

4. The dividing groove in full, to the edges, is filled with a special acrylic mass for sealing joints.

5. To the floor and walls, with the help of self-tapping screws, floor, wall and ceiling, closing frame, wide profiles are attached. Between the metal profile and structural elements, do not forget to fix the felt or mineral wool strip, to ensure the gap of the sound bridge.

6. If the partition is mounted in an attic with a slope, in this case, an L-shaped profile is used on the ceiling of the attic. It is attached, like a wall guide profile, to only one side of the groove that breaks the sound transmission.

7. Between the frame parts screw vertical U-shaped profiles. During installation, they can be set against each other, or it can be shifted and fixed in a checkerboard pattern. The distance between them depends on the size of the selected drywall boards.

8. The joints should be centered on the rack profile. This allows you to firmly fix the plate. The distance between the mounting points can withstand about 25 cm. First, the skin of one side is mounted. Then, if necessary, we lay the cables, lay the insulating material, and plating the other side of the partition with plasterboard plates is performed. Joints between plates are sealed with putty for joints.

9. If necessary, if a door is provided in the partition, bars are inserted and screwed into the side metal rack profiles. They give rigidity to the structure. For the installation of the door frame, there are special profiles, of which the necessary parts are cut and fixed in place.

Installation of double partitions, design features

When installing double partitions with enhanced sound insulation, the frame profiles are alternately screwed to the right and left to the jumper with a wider frame profile.

Similar to the first option, the necessary cables are laid inside. When laying the slabs for heat and sound insulation, it is necessary to ensure that these slabs are tightly sandwiched between the profiles.

After installation of the first layer of drywall boards, their joints with the floor and side walls are filled with a long-lasting elastic acrylic mass. Then proceed with the installation of the second layer of drywall boards.

They are mounted with a shift of the joints in relation to the first, then all joints of the plates are plastered with a gypsum mass. The result is an even base for wall decoration.