Search

Login

How to build a bath or sauna yourself

The pace of modern life, especially in a city, leads to the accumulation of negative emotions, fatigue. How to eliminate the negative consequences, remove toxins and toxins? Of course, with the help of the bath, especially when it is built with your own hands.

Content

- The foundation of the bath

- Log Walls

- caulk

- Coatings, ceiling, bathhouse roof

- Bath floors

- Bath ventilation

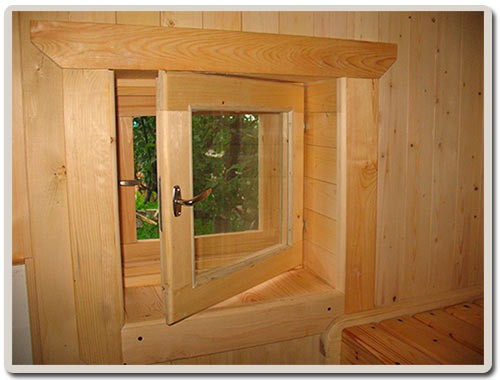

- Windows, bath doors

- Bath equipment

- Sauna, decoration features video

The foundation of the bath

The first step in the construction of any bath or saunas, is the construction of the foundation. The foundations make tape and columnar, laying them 15-20 cm below the freezing depth. Column foundations are suitable for walls of lightweight structures. They are several times cheaper in terms of labor than tape.

column foundation

Chopped and block-shaped baths, where you do not need to make bridges between the columns, are usually erected on columnar foundations.

When erecting such foundations, the following rules must be observed:

1. Pillars are placed at all angles of the external walls of the building, at each intersection of the internal walls with the external and with each other;

2. Depending on the load on the foundation, poles are installed around the entire perimeter of the structure with a certain step (from 1.2 to 2.5 meters);

3. Between the pillars, it is necessary to lay out the base, which should rest on the jumper between the posts, the jumper serves to tie the posts together, and also serves as the basis for the base.

foundation of concrete blocks

It is possible to establish a foundation of concrete blocks and slabs laid under the entire perimeter of the building directly on the ground. Burrowing, thawing, subsidence of the ground practically do not threaten such a foundation; such a foundation is suitable for small compact buildings, specifically for baths.

Walls

log cabin

The best are those baths that are composed of logs or timber.

It is desirable to choose logs of the same thickness.

Walls made of logs or beams keep heat well, they breathe, let in steam and air.

The ends of the logs are chipped from the inside to a thickness equal to the upper diameter of the log, while professional carpentry tools are used.

It is necessary to squeeze the logs from the top to the butt, this eliminates badass.

The walls consist of individual crowns, i.e., connected to each other separate bars or logs.

The first crown is made of thick logs, it is called the first crown, the rest with a smaller cross section and they are called ordinary.

From the crowns they add a log house.

If the log house is folded from logs, their ends usually extend beyond the walls, such a design of the corners is called in the region.

To save material, angles are performed without the ends coming out - into the paw.

Which way is better? A bathhouse chopped with the release of the ends is warmer, but will cost more, since more forest is needed.

The bathhouse, cut into the paw, is colder, and the ends of the log house will need to be closed with overhead boards, as the sawn wood decays quickly.

You need to know that a sauna felled in a corner is more traditional, and in a paw - modern. Each owner has his own concept of the appearance of the bath, so the choice of the method of cutting the corner is a matter of taste.

felling in the paw

Felling in the paw is made of logs of the same size, wood must be of high quality.

Crowns for strength are fastened along the length of the spikes, the thickness of the spikes is 25 mm., Width 60-70 mm., Height 120-150 mm. Nests for spikes are made on 20-25 mm. deeper. For strength bonding of logs is done in the form of a dovetail.

Caulking

At the end of the construction of the walls, they must be caulked using tow, hemp, moss, flax. felt.

Caulking is performed twice: immediately after setting the log house, then 1-1.5 years after the termination of shrinkage. Caulk the whole crown around the perimeter, otherwise the bath warps. Caulking walls rise 10-15 cm.

At the end of caulking, the seams are closed with wooden slats.

Coatings, ceiling, bathhouse roof

Covers are attic and without attic.

Both coverings consist of a ceiling and a roof. In these ceilings, a ceiling is attached from below.

Floor beams are most often made from coniferous wood.

The ceiling is made of any material with low thermal conductivity.

Wooden ceiling can be: panel, flooring, hem.

The roofs of the baths can be single and double.

Rafters - the main bearing element of pitched roofs; for rafters, bars from well-dried softwood without knots and cracks are used.

Roofing material: slate, metal profile, metal tile, roofing steel.

Bath floors

Floors come in two types: concrete and wood.

Concrete floors are made in the washing and steam rooms, with wooden gratings installed on them.

In the dressing room you can make wooden floors with insulation.

In the washing and steam rooms you can make the floor from wooden boards, and you can do it in two ways:

Wooden non-leaking floor and wooden leaking floor.

To prevent the floor from leaking, boards are laid along the logs with a slope towards the middle or with a slope to one side, a grate is placed in the recess, and a water sump is located under it.

This is an easy way, but the floor will always be cold, the boards will not dry out completely and will rot.

In order for the floor to be leaking, crushed stone with sand is laid on the ground, poured with concrete, the slope of this floor is directed to the mouth of the funnel, in which a container for collecting water is arranged, then the floor is already covered, the boards are not tightened, leaving the distance between the boards up to 2 cm.

Bath ventilation

To preserve the floor and walls, good ventilation under the floor is required, which is achieved by placing the furnace blower - the heater below the floor.

Windows, bath doors

Doors and windows of the bath do smaller than in residential premises.

The height of the door from the floor is 160 - 180 cm. The threshold height is 15 -20 cm., The width of the door is 65 - 80 cm. The door should open outwards.

Door handles should be wooden, well polished.

The window in the bath is made horizontal, since such a window retains heat better, its height is from ⅔ to the length (30 x40, 40x60).

The windows should have double glazing, it can also be done on a single frame by placing glass on both sides of the frames.

So that the window does not sweat, it is necessary to achieve a tight fit of the frame to the binding and the glass to the frame, to cover all the cracks with lime - cement mortar.

Lighting washing and steam rooms can be provided through windows made in the doors. Artificial lighting is carried out by hermetic lamps.

To ensure the influx of fresh air into the bathhouse, near the stove - heaters at a height of not more than 0.5 meters from the floor, a forced-air vent is closed, closed by a valve or damper.

Outside, this hole is covered with a perforated plate to protect from wind.

With the upper position of the ventilation hole, the warmest air leaves, the lower the discharge hole, the higher the degree of heat use from the stove.

Of course, air removal from a low located hole is possible only if there is a draft created by a special ventilation pipe. By inserting doors and windows, performing a ventilation system and installing a stove heater, we can assume that the bathhouse is built.

Bath equipment

The equipment of the bath is made from planed boards - these are benches, benches, shelves. The shapes and sizes depend on the size of the steam room.

The location of the shelves is possible in two, three tiers, the width of the shelves decreases from top to bottom.

To use a broom, sitting in the hottest place, the distance from the upper shelf to the ceiling should be 110 - 12 cm, in relation to the upper stones of the furnace, the shelf should be 15 cm higher.

The best material for wood steam equipment is linden, aspen, poplar, they do not burn the body and dry quickly.

It is very good to build a bath, if the size of the land allows, next to a reservoir (pool, pond or riverbank).

After the steam room, cold water is very useful for blood vessels.

And to dive or plunge into a reservoir is an indescribable pleasure.

In winter, you can cut a hole in the outdoor pool, which goes into wintering with water, or in a pond. Plunging into the hole you will experience true bliss.

Construction of the sauna, decoration features

The main difference between the sauna and the Russian bath is that in the sauna the air is hotter up to 130 degrees, but less humid 4-5%.

The air temperature in the Russian bath is 40-60 degrees, and the humidity reaches 40%. The sauna is smaller than a Russian bath, its size is 2.5x2x2 meters.

Shelves are arranged in a steam room in two tiers, the upper one at a distance of 1 meter from the ceiling, the lower 70 cm from the top.

In the sauna, water is not needed, as in the steam room you can’t wash.

In a modern sauna, metal stoves are used, which are heated with wood or electricity.

When steaming in the sauna, the furnace heats up continuously, a safety fence is necessarily installed around the furnace.

The walls of the sauna are made of wood, the main requirement for the walls, the ceiling of the steam room is good thermal insulation eliminating heat loss.

For the walls of the steam room, dried boards of aspen, birch, linden, poplar are used, since they have low thermal conductivity and do not warp from steam.

The surface of the walls of the steam room can not be varnished, drying oil, paint, as they prevent the absorption of moisture by the tree.

Good insulation of the ceiling is important.

A log sauna does not require ventilation.

Whole logs breathe, thanks to which the humidity in the sauna is automatically regulated.

The smell of wood lasts a very long time.

The logs for the sauna should be aged, dried to a moisture content of 10-15%.

They are tightly fitted to each other and well caulked.

The paneling inside the sauna is made of grooved boards with a thickness of at least 16-20 mm., The thicker the board, the better the vapor is absorbed and the smell of the tree lasts longer.

The insulation under the inner lining must be completely vapor-proof and heat-resistant.

For this purpose, high quality construction paper on aluminum foil, or fiberglass reinforced with a double layer of foil, is used.

The shiny side of the membrane should face the sauna room.

All standard insulation materials are effective if used correctly and have the required thickness.

In a simple log sauna, the ceiling can be made of unplaned boards.

The highest temperature in the sauna is at the ceiling level, in order not to lose this heat, the insulation of the ceiling needs to be done better than the insulation of the walls, and the vapor barrier must be arranged more efficiently.