Search

Login

We build a house from wood concrete: the composition of wood concrete, finishing a house from wood concrete

Most of the investment in building a house is in the construction of the foundation. The heavier the building, the more powerful the foundation is needed. To save on construction, it is necessary to facilitate the construction of the house. We propose to consider the option of building a house from wood concrete.

Content

Compare the properties of some building materials

The choice of building materials is currently very good.

But each developer tries to reduce the cost of construction, so he evaluates the pros and cons of each material, in search of the optimal solution.

It is very important that the material meets all the necessary requirements in terms of environmental friendliness, is durable, and has good thermal insulation properties.

With all this, it is desirable that the construction of the house is not delayed.

gas silicate blocks

Firstly, this is a concrete product.

Secondly, this is a rather complicated material, since it has a certain styling technology.

Thirdly, buildings from silicate blocks require brick cladding, and this significantly complicates the construction, which leads to the fact that it is necessary to build a more powerful foundation, with a base width of up to 50 cm.

All this leads to a significant increase in the cost of construction.

wooden house

A wooden house (timber, cylindering, logs) is wonderful materials, environmentally friendly, it is easy to live and breathe in these houses.

But there are also disadvantages - a very long construction, high fire hazard.

The extension of the construction period is due to the fact that after the construction of the log house, it is necessary to wait more than a year when the log house settles, double caulking requires large labor costs, the need for antiseptic treatment.

brickwork

The calculation of the thermal conductivity of the walls shows that in the middle zone of Russia it is necessary to erect walls in three bricks, and this is a lot, long and expensive.

As in the case of gas silicate blocks, such wall thickness and, accordingly, increased load, necessitates the construction of a reinforced foundation.

This naturally increases costs.

what is arbolite

Arbolit is a lightweight concrete with a large-pore structure; it consists of 80% mineral aggregates (logging waste, wood processing, flax and hemp waste and other cellulosic raw materials), as well as chemical additives (mainly aluminum sulfate, which neutralizes sugar contained in wood) and water.

Arbolit is easy to install, it is enough to plaster the walls from it from the inside, then you can make any interior decoration. The great advantage is that nails are easily driven into the arbolite, screws are screwed.

The main argument in favor of wood concrete is that it does not need to build a powerful, expensive foundation, as is required when building a house from gas silicate.

Arbolite wall blocks are significantly lighter than many other building materials.

The mass of 1 square meter of the wall of the house made of this material is three times less than expanded clay concrete and eight times less than brick, which allows to reduce the load on the foundation and structural load-bearing elements.

Although the thermal conductivity values \u200b\u200bof arbolite and gas silicate are similar, but from an environmental point of view, arbolite wins significantly.

Arbolite is based on wood chips, and gas silicate consists entirely of chemical components.

It is not surprising that some people cannot live in houses of gas silicate blocks, for some people in such houses it is even hard to breathe.

Therefore, although gas blocks are cheaper, but health is more expensive. Among other things, a box of wood concrete is put literally in a couple of months.

We put a box of wood concrete

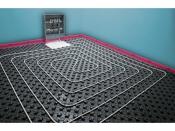

Due to the fact that the future home will be relatively light, the foundation can be made on stilts by deepening them one and a half meters in increments of 1.2-1.5 meters. A basement thickness of 40 cm is sufficient for the erection of walls that fit into one block.

A standard block of wood concrete with a thickness of 30 cm. In terms of its heat and sound-proofing properties, it corresponds to a brick wall 90 cm thick, and a classic wooden one - 50 cm thick. Therefore, it does not require additional insulation, which has been tested in practice.

With all this, on the arbolite surface, due to the lack of fragility of the material, finishing materials are well attached.

For decoration, you can use any of the finishing materials (siding, blockhouse, etc.). For all this, the cost of the foundation is quite acceptable. A month later, after the foundation gains the necessary strength, construction can continue.

Due to the fact that arbolite blocks have good geometry, masonry is very fast, but when buying blocks, it is necessary to purchase halves, the so-called shorty.

Otherwise, the blocks will have to be sawn, and this material with great difficulty, only a Bulgarian with a disc takes it - for metal. Due to the strength of the material of the block, the disks often have to be replaced; they last only for 5-6 blocks.

The overlapping of the first floor can be made wooden, at the end of the laying of the first floor, you can make a reinforcing belt. In order for the house to be warm, it is necessary to exclude the so-called cold bridges.

In block houses, they arise at the place of masonry joints. Now on sale is a dry masonry mix Pemix, based on expanded perlite. It is lightweight, environmentally friendly, plastic, well protects from the cold.

Finish

After waiting for the walls to dry, you can begin decorating.

While the house is not finished from the inside, it soars, i.e. water vapor escapes through the blocks. This proves that the house really breathes, like the buildings made of real wood.

The house can be plastered both inside and out.

Outside, you can paint with facade paint, that's all.

Here you have a huge savings in finishing materials.

Inside the house, you can stick on the stucco just a wallpaper. Since the walls are even, the plaster falls flat on them, the wallpaper is glued easily, it keeps well.

Although the arbolite is sawn and poorly, but the nails enter it without difficulty, and it is very difficult to pull them out later, this arbolite wall resembles a wooden one.

On walls made of wood concrete, shelves and cabinets of a kitchen set are hung. And all this is fastened tightly.

Arbolit has a very good vapor permeability. This means that the house will not only be warm in winter and cool in summer, but also air humidity will always remain comfortably low.

In such rooms there is never dampness, this material absorbs moisture well and also gives it well.