Search

Login

Parquet board, parquet and laying methods

Parquet floor - it's beautiful, environmentally friendly. How to choose and how to properly stack, we will tell in this article.

Content

- What is a parquet board?

- Parquet board structure

- The thickness of the floorboard, its durability

- Parquet laying video

- Bypass pipes when laying

- Parquet, what is it? video

- Screed flooring scheme

- Popular drawings of parquet masonry

- Docking difficulties

- Deck laying

What is a parquet board?

Parquet board is a three-layer plank, the length of which is from 210 cm to 225 cm, width is 18-20 cm, thickness is 1.4-1.5 cm.

The upper front layer of the parquet board is made of solid wood, the next two layers are made of more accessible conifers.

In order to minimize warpage of the board with changes in temperature and humidity, the lower layers are oriented along the fibers perpendicular to each other.

A modern parquet board is equipped with a locking joint system, this eliminates the need to use glue during installation.

The spike of one board is simply inserted into the groove of the other at a certain angle and snap the lock.

Such a coating can be disassembled and if you act carefully and not damage the lock, if necessary, transfer to another place and reassemble.

Parquet board structure

The bottom layer of the floorboard is veneer.

The middle layer is coniferous. The top layer is a valuable tree. Several layers of varnish or oil are applied on top.

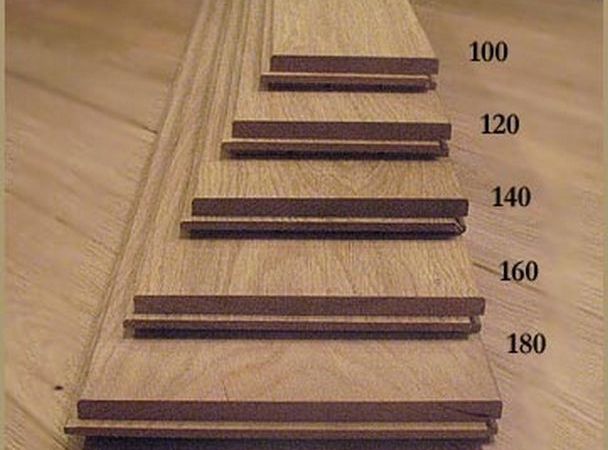

The thickness of the floorboard, its durability

The thickness of the floorboard is in the range of 14-15 mm.

The decorative layer has a thickness of 3.5-4 mm. On average, the coating of the floorboard, lasts about 20 years, more precisely 10-30 years.

Manufacturers believe that such a floor can withstand two polishes, which are carried out once every 7-8 years.

However, it should be noted that neat owners try to prevent wear on the wood, polish the floor as the lacquer abrades, then apply a new coat of varnish.

Modern grinders are capable of removing a minimum layer of one millimeter and even thinner. It is clear that with this method of operation, boards can transfer at least five polishes.

The increase in the thickness of the decorative layer to 6 mm., Significantly increase the shelf life of the decorative coating, allowing you to produce more polishes.

The thickness of the improved parquet board is 20-22 mm., Thereby increasing the cost of such a board by 15-20%.

There is also a thin parquet board, its thickness is 7-10 mm. This is the most economical version of the boards, they are great for quick repairs. But thin boards have a small thickness of the upper layer (0.7-2.5 mm.) And they can not be sanded.

Parquet laying

Stackers, most often, use the floating method of flooring.

This method is the fastest and most affordable, but at the same time, the area of \u200b\u200bthe room should not exceed 150 square meters.

When laying a parquet board, each room in the apartment should be considered as a separate area of \u200b\u200bcoverage.

It is imperative to leave compensation clearances at the rate of 1 mm. per linear meter of room size.

If the gaps are less than necessary for a given floor area, then with an increase in humidity, the boards can rise uphill.

Bypass pipes when laying

In the case when the surface of the floor, perpendicular to it, pipes intersect - you need to get around them.

Make the necessary measurements, drill holes that should be 20 mm. larger than the diameter of the pipe, saw off the edge of the board, as shown in the figure.

After laying the board, the cut segment is glued in place and the edge of the hole is closed with a suitable metal or plastic ring.

Parquet, what is it?

Parquet - This is a rectangular plank, which is made of a single piece of wood. On the sides of the slats, for reliable fastening to each other, there are grooves and ridges.

The Russian GOST862.1-85 piece parquet regulates the requirements for the characteristics and quality of the coating, but it is hopelessly outdated.

In accordance with GOST, hardwood flooring must have a thickness of 15 mm.

For softer planks made of softwood, the thickness is 18 mm. Currently, parquet from coniferous species is practically not found, with the exception of larch parquet.

The modern market of building materials, has long been producing products with a thickness of 22 mm., Not mentioned by GOST.

Such parquet is intended for rooms with high impact mechanical stress.

GOST regulates the length of the parquet plank within 500 mm., And everything that is longer is attributed to a massive board.

In the domestic market, the length of parquet planks varies within 200 mm

Screed parquet cake layout

The screed should be strong and even, performed with a specially prepared solution.

The underlay for the parquet is made of moisture-resistant plywood and is attached to concrete with adhesive mastic and in some places with a dowel-nail.

Then parquet glue is applied and parquet is laid with the help of nails (finishing). After all this, the parquet is primed and covered with parquet varnish, the varnish is applied in several stages.

When laying the parquet on the logs, other methods are used, the methodology of work can be seen in the second figure. Parquet cake - this is the name of this whole procedure.

Popular drawings of parquet masonry

A popular pattern for parquet masonry is the Deck. This masonry with an irregular shift of the parquet strips, due to this, the floor surface does not look too monotonous.

Braiding is a complicated pattern, made of two parquet planks.

The Christmas tree is single - here the planks are located at an angle of 90 degrees in relation to each other.

Rhombus from several levels. When recruiting such a picture, the trims are cut, this increases the consumption of parquet.

Visually, rhombs of the same size form hexagons.

Docking difficulties

Piece parquet is usually laid on the underlying layer of moisture-proof plywood, while using nails and special glue.

It is often difficult to connect parquet strips of the same thickness from different manufacturers. This happens when, according to the designer, the artistic flooring solution is a combination of wood of various species.

This is due to the unequal location of the ridge and groove. Although the total thickness of the parquet strip is 15 mm, some manufacturers have a top layer of wood up to a groove of 7-8 mm. And others 5 mm.

It would seem that the thicker the top layer, the more polishing the parquet can withstand, but the closer to the front surface the groove and crest, the more rigid and monolithic the floor structure.

Such problems can be solved by modern parquet technologies, but in each case individually.

Deck laying

The main difference between piece parquet and solid wood flooring is the ability to create many design options.

There are hundreds of unique styling patterns that can support or define the style of any interior. But the most widespread, in view of its simplicity, is the so-called Deck.

In this case, laying, planks are arranged parallel to each other according to the principle of an endless board. At the same time, a straight deck, when the planks go along the walls, is a practically non-waste option. By purchasing this flooring, only 5% must be purchased in reserve. But such a surface is pretty monotonous.

There are several ways to revitalize this floor.

You can use wood with a pronounced pattern and color inhomogeneity.

You can combine regular and irregular shift of the bars.

You can lay them diagonally, due to this the room is visually extended in the direction of the diagonal.

It looks very interesting floor with alternation - regular or random.

Alternation can occur according to a given pattern using several species of trees, especially contrasting in color.

The above methods for deck laying brings parquet closer to the artistic.