Search

Login

Pump for increasing pressure in the water supply network, types of pumps, how to choose the right

When water flows out of the tap in a thin stream - this not only annoys, but also interferes with the normal functioning of household appliances, depending on the pressure of the water. The solution to this problem, in most cases, is to purchase a pump to increase the pressure of water, of which there are a great many on the market. At the same time, a huge variety of pumps is distinguished by operational characteristics, cost and other parameters.

Content

- Reasons for low water pressure

- Ways to eliminate low water pressure

- Criteria for choosing a pumping device video

- Booster Pump Classification

- Grundfos and Wilo pumps

- Installation and connection of booster pump

Reasons for low water pressure

To eliminate the low water pressure in the water supply system, you must first find out the reason for the decrease in water pressure, and then proceed to solve this problem.

Factors contributing to a decrease in water pressure:

- Clogged indoor water pipes - manifests itself when people living on floors lower and higher have normal water pressure;

- Inadequate maintenance of the common house pipeline - it is observed when throughout the house, for a long time, the pressure of water becomes less and less;

- Congestion of public water supply networks - occurs when the necessary amount of water consumption is incorrectly calculated, especially in the spring-summer period of mass watering of household plots, or in the morning and evening hours, when the bulk of the people are at home. In high-rise buildings, network congestion is manifested in the complete absence of water on the upper floors.

So, finding out the source of pressure reduction, you can begin to correct the situation.

Ways to eliminate low water pressure

It would seem that the solution to any problem is associated with alternative options.

However, with poor patency of water pipes inside the apartment, the only way out is to exchange them for new pipes.

In the absence of normal maintenance of the common house water supply, you will have to file a complaint with the company managing the house, or the administration at the place of residence.

With overloaded utility networks and the absence of blockages in the pipeline, there are 2 options for overcoming the current situation:

- Installation of a domestic pump design in-line - suitable for increasing a small pressure of water, if the existing pressure is at least 0.2 atmosphere;

- Installation of a pumping station - is necessary when there is a complete or partial absence of water in the tap relative to a specific time of day.

However, the purchase of a pump is always associated with certain difficulties arising from the large assortment of necessary goods.

Criteria for choosing a pumping device

The variety of various equipment on the modern market, along with professional managers, can confuse even a highly qualified specialist, not to mention a simple person who first encountered the problem of choosing a water pump. In order not to fall into the trap of skilled sellers and not to purchase a pumping station, instead of a pump that is quite suitable for the functions, when choosing equipment, you should consider:

- The operational characteristics of one model of different manufacturers may vary slightly, but differ, so the equipment should be selected in relation to the specific situation;

- The fame of the manufacturer serves as a significant guarantee of the purchased goods, while the device of an unfamiliar company can last 1-2 months, although it costs much cheaper;

- The noise level produced by the unit during operation sometimes plays a very important condition, especially when used in multi-apartment buildings;

- Financial resources should also not be discarded, because when choosing equipment there is always an alternative.

Booster Pump Classification

Today, water pumps for increasing pressure are in fairly high demand, therefore, more advanced pump models are constantly appearing on the market, expanding the already huge assortment. Moreover, all pumps can be grouped relative to a specific characteristic.

Based on the function, pumps that increase the pressure of water are divided into the following types:

- Compact in-line booster pumps designed to correct and increase low pressure in a water pipe system;

- Centrifugal pumps with a hydraulic accumulator can not only adjust the pressure, but also raise the water from a sufficiently low level.

The operation of the pumps occurs through:

- Manual control, when the unit runs continuously regardless of the water supply, and shutdown is only forced. Such a model must be turned off on time in order to avoid overheating and, as a consequence, failure;

- Automatic mode, when the pump is equipped with a flow sensor, through which the motor starts when the water is turned on. In this case, the operation of the pump ceases from the moment the valve is closed, helping to extend its operational life.

Based on the method of cooling a running motor, pumps are allocated:

- With a dry rotor, the engine is cooled by means of special blades mounted on a drum and not in contact with water. Such pumps are characterized by an acceptable degree of noise produced during operation at a rather high efficiency. However, the engine in such models is separated from the hydraulic part by a stuffing box seal on the end of the axis, which tends to wear out. The rolling bearings located in the design will also require replacement over time, so pumps equipped with a dry rotor require periodic maintenance.

- With a wet rotor, the mechanism is cooled by the pumped water, and since all rotating structural elements are involved in the process, such pumps are silent. In addition, the role of rolling bearings is played by plain bearings that do not require any maintenance. In pumps equipped with a wet rotor, there are no glands, due to which the pumps are called glandless. However, such pumps have a slight minus - the pumped water should not contain foreign particles that contribute to the breakdown of the pump.

In addition, pumps are:

- Single stage;

- Multistage pumps are distinguished from single-stage pumps by higher efficiency with significant energy savings and low pump power, since the design includes several impellers, moving through which water gradually gains the necessary pressure.

Grundfos and Wilo pumps

At present, grundfos pumps for increasing pressure, which are manufactured by the Danish concern, are widely used. However, a German-made Wilo water pressure boosting pump is in no way inferior in performance to the Grundfos pump.

Models of these manufacturers are in high demand due to a number of advantageous features:

- Compactness;

- Excellent corrosion resistance;

- Virtually silent operation;

- Possibility of mounting directly on the pipeline;

- Low power consumption;

- Presence of sealless models;

- Easy installation.

With all the advantages of these pumps, the only drawback of foreign products is the cost, significantly exceeding the cost of pumps of domestic manufacturers.

Installation and connection of booster pump

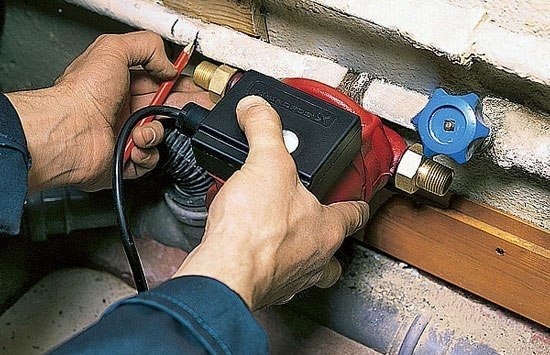

In order to learn how to install a pressure boosting pump for a particular model, you must first look at the attached instructions. In this case, the simplest models (for example, Grundfos UPA 15-90) are installed as follows:

- On the water pipe, at the intended location of the pump, markings are made relative to the length of the pump, taking into account the adapter;

- Overlapping water, the remains of which descend through the tap;

- The pipe is trimmed in the intended place;

- To install the pump, a thread is cut from the outside of the pipes onto which an adapter with a female thread is screwed;

- The fittings that are included with the purchased pump are screwed into the adapter, as well as into the valve;

- The pump is installed.

Connecting a pump to increase pressure is as follows:

- In the shield, a separate machine, RCD is installed on the pump line;

- A three-core copper cable extends from the shield to the installation site of the pump;

- An outlet is installed near the pump and can be connected.

Despite the elementary nature of the installation of this model, more complex designs require some experience, therefore, when purchasing a pumping station, it is better to contact specialists and then the installed pump will last for more than one decade.

Thus, when choosing a pump for increasing pressure, the price of which is very low, it is worth circumventing, because after saving a few rubles you can purchase a low-quality unit that will last a year, and even in the best case.