Search

Login

Recommended

Polyurethane foam, how to choose where polyurethane foam is applied and methods of application

Not so long ago, summer residents and builders were racking their brains on how and what to fix the seams and cracks in buildings with the greatest efficiency and at the lowest cost. Any suitable materials were used, up to light industry waste. And now everyone is puzzling how to choose the right one from the whole variety of different sealing materials and compositions presented in stores. The problem, changing focus, remained. Indeed, dozens of manufacturers offer the same mounting foam in different packaging, color shades and with a price that is different at times. How not to get confused here? We’ll try to figure it out.

Content

- Polyurethane foam properties and characteristics

- Foam Application

- Polyurethane foam professional video

- Polyurethane foam winter

- Polyurethane foam fire

- Surface treatment after using foam video

Polyurethane foam properties and characteristics

The chemical industry learned to produce polyurethane-based polyurethane foam more than half a century ago, but these products found widespread use not so long ago, in the mid-80s of the last century, due to a significant reduction in the cost of production technology. This material consists of two main components made from polyol oil and isocyanate and belongs to the construction class of sealants.

In the production of various fillers used stabilizers, dilators, catalysts and additives for foaming the composition. In addition to the sealing function, the additional properties of mounting foam are also appreciated:

- soundproofing

- thermal insulation

- ability to connect and fasten structural elements

The most well studied and widely used in construction and finishing works, as well as in the repair of the following characteristics of polyurethane foam:

- primary expansion, i.e. the ability of the foam to actively expand in a short period of time, immediately after the composition leaves the container or balloon

- secondary expansion, i.e. the property of the foam to expand further during the entire period of crystallization (solidification). Secondary expansion is directly proportional to shrinkage. The magnitude of the secondary expansion must be closely monitored, since if its value is large, cracking and the formation of cracks are possible after complete drying of the composition

- the output volume of the foam, i.e. the amount of expanded and solidified substance, measured in liters. The volume is able to vary depending on external environmental factors (air temperature, humidity and even wind)

- adhesiveness i.e. adhesion ability. This parameter allows you to choose the right foam for work with various building materials (wood, plastic, metal).

The price of polyurethane foam has a significant variation, since the cost depends on many factors (characteristics, properties, types of packaging, method of use and purpose, etc.)

Foam Application

Foam is used for the initial installation and sealing of window, door and attic blocks, as well as various connecting structures, a similar composition can be used for insulation of network communications (pipes and water hoses located outside of warm rooms), also foam is suitable for sealing joints and cracks in wood, plastic or metal. If it is necessary to fill in significant voids quickly and maintain sound and heat insulation at the same time, there is no better way than using foam. This material even makes nice sculptures, but this is a topic for a separate article.

Polyurethane foam professional

Professional polyurethane foam has a special marking showing the exit of the foam from the cylinder, expressed in the volume of liquefied gases pumped into the cylinder for foam under normal conditions (the numbers are usually 50, 65, 70). Professional foam is usually used with a reusable gun for mounting foam (a special valve should be on the container).

As a rule, pistols provide the ability to adjust the amount of incoming composition. With the outlet closed, the foam in the gun does not freeze, and the nozzle must be flushed after each use.

Polyurethane foam winter

There is a winter version of the mounting foam, which differs in chemical composition from the usual one. It does not break up when working with air temperatures up to -20 degrees.

However, in order to have a maximum yield of the composition, the cylinder must have a positive temperature, therefore, when working in winter conditions, it must be regularly heated.

Polyurethane foam fire

Manufacturers of polyurethane foam provided several classes of composition depending on high temperatures. Three types of foam are shared:

- fuel that can be used in non-residential premises and for connecting metal structures on the streets is marked as B3

- self-extinguishing, B2

- fireproof, fully fireproof, marking B1

When choosing a foam, it is necessary to provide all possible options for its use, depending on fire safety requirements.

Surface treatment after using foam

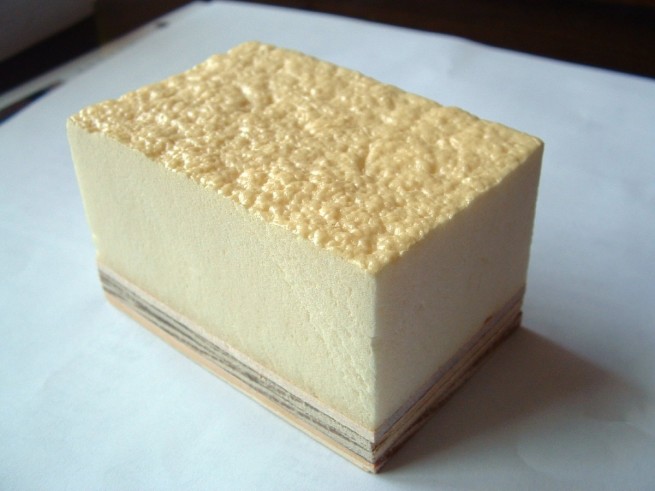

After the foam has hardened, it usually has a light yellow color. Gradually, in the light, the foam darkens after a certain time and decomposes under the influence of ultraviolet rays, this leads to its fragility and loss of properties.

Places filled with foam require processing after it has hardened. Excess foam is removed with a knife, and the surface after removal is sealed with a mounting tape and painted over. There are several ways how to remove the mounting foam that has fallen into the wrong place, but most simply this can be done with a special cleaner or acetone that dissolves the hardened composition.