Search

Login

How to properly prepare a cement mortar from different grades of cement, how to use it correctly

A zealous and economical owner, many, sometimes even complex, construction works are able to perform independently. Moreover, if these works do not require a certain qualification, and the materials are readily available. The preparation of cement mortars at a construction site is trusted even by a handyman. Can't we ourselves carry out this laborious, but technologically uncomplicated process? Of course we can! It is only important to know the brand of cement and the proportions of the mixture. And it is also advisable not to confuse cement mortar with concrete. This will be discussed in this article.

Content

- Cement brands

- Types of Cement Mortars

- Cement-sand mixture preparation video

- Preparation of cement-lime mixture

- The use of cement mortars

- Characteristics of cement mortars video

Mortar brands

For the production of cement mortars, various grades of cement can be used. The marking of this building material includes alphanumeric designation. The most common letters M simply mean the word mark and Portland cement.

The letters BC are also quick-hardening and SS sulfate-resistant (used when in contact with chemically active soils, i.e. if there are doubts about the composition of the soil in which it is planned to build a foundation for the house, the earth should be examined and if it contains an increased content of sulfates , for pouring the foundation it is necessary to use cement SS).

The digital designation shows the pressure in kilograms per cubic centimeter that can withstand the hardened composition.

Accordingly, the solutions with the use of cement grade 500 have the greatest strength.

Types of Cement Mortars

According to the proportionality of the binders included in the mixture, the solutions are divided into the following types:

- fatty solution in which the content of the binder component is overestimated

- normal solution with the correct proportions when mixing

- lean solution with insufficient binder

Fatty solutions quickly set, but after drying often crack, skinny on the contrary, solidify slowly, but after drying do not give sufficient strength. For some types of work, fatty and skinny solutions are needed, but it is usually used, of course, normal, with clear proportions of the components when mixed.

In composition, the solutions are distinguished by the names of their constituent components, the most common cement-sand and cement-lime.

Cement-sand mixture preparation

Cement solutions are easy to prepare. Water is added to the cement-sand mixture, made in a 1: 3 ratio and thoroughly mixed, without stopping stirring.

If there is a lot of water and the solution turns out to be liquid, it is necessary to add cement, if on the contrary a thick solution add sand and water. To prepare the cement-sand mixture, only marine (or river) alluvial well-sifted sand is used, which differs in the fraction of crystals having the smallest size.

The shelf life of the solution is not more than an hour and a half, if it is not possible to use the time for use, you can increase it by constantly interfering with the finished mixture. Special nozzles for electric drills will help in the process of constant mixing.

A cement-sand mortar is used for primary decoration or as a masonry, as it is very durable, but not plastic enough.

Cement-lime mortar preparation

For finishing, you need to use a cement-lime mixture.

Such a solution is prepared similarly to cement-sand, only liquid diluted lime is added instead of water. To increase the pour point, gypsum can be added to the cement-lime mortar; this solution is used only for internal work.

The use of cement mortars

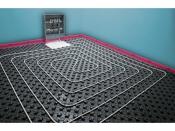

Many confuse the concepts of concrete and cement mortar. It is easy to remember their differences from each other in the production of cement mortar. Three components are used directly, cement, water and sand. And in addition to the concrete add fillers, most often crushed stone. The scope of the cement mortar is the laying of bricks or other building material (for example, cinder blocks), as well as finishing work (mainly plastering and leveling surfaces, as well as the manufacture of screeds).

Masonry cement mortar, in addition to the ideal quality of the main components, must be plastic, which is why it is necessary to use special plasticizers (chemical additives) in its preparation, as well as add clay or lime in various proportions.

Concrete is necessary in the production of reinforced concrete products, as well as to fill the voids associated with side works in construction (for example, filling the blind area near the house). Recently, concrete is often used in monolithic construction, filling it with formwork in multi-storey construction.

Characteristics of cement mortars

The performance characteristics of cement mortars correspond to the characteristics of the cement from which they are prepared and classified according to density (depending on the type of cement from more dense 500 to less dense 200), ductility and water resistance. An important characteristic is the mobility of the solution, i.e. its ability to spread under the action of its own mass. To determine the mobility, a special metal cone weighing 300 g with an apex angle of 30 and a height of 15 cm is used. The deeper the cone sinks, the more mobile the solution. The verification process is shown in detail in the video.

The service life of a cement mortar also depends on its constituent components and can in no way be less than 25 years, of which half the mortar gains strength and the second half begins to lose it.