Search

Login

Recommended

What is a roof passage, types and methods of installation of roof penetrations

The roof hole for ventilation and the removal of contaminated air from the room is called the roof passage. Most often, do-it-yourself roof passage is equipped in private houses with stove heating, where it acts as a chimney. Since there are a great many types of roofing, there are also plenty of options for installing roof units.

Content

- Types and forms of roofing

- Installation of a roof passage on a pitched roof

- Sealing the roof at the chimney outlet

- The passage of the chimney pipe through the roof video

- Features of the installation of a round chimney

- Roofing installation video

Types and forms of roofing

Depending on the type of ventilation or design of the furnace, the passage through the roof can be:

- round;

- square;

- oval;

- rectangular.

Its location depends on the type of roof and the angle of the roof.

The node of the passage through the roof is usually equipped with:

- when changing the heat source (furnace, heating boiler);

- with a serious repair of the roof, with the replacement of not only the top coating, but with the reconstruction of the rafter system;

- during the construction of a new building.

Depending on the shape of the passage and the material used to cover the roof, the methods of the chimney flue also differ.

Installation of a roof passage on a pitched roof

Starting work on the arrangement of the chimney, it is necessary to take into account the design of the roof and the angle of its inclination. As a rule, the future stove heating pipe is mounted near the ridge in order to avoid a large accumulation of precipitation in winter (snow) and to reduce the formation of condensate. Indeed, the closer the chimney to the ridge, the lower its height and much less various adverse factors act on it.

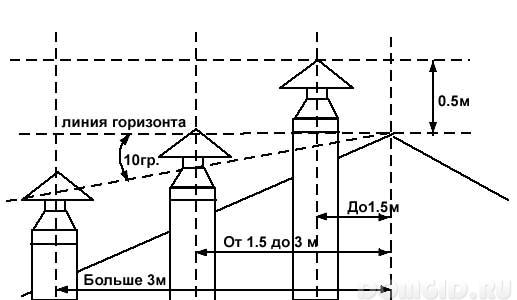

The height of the pipe installed at a distance of up to 1.5 m from the ridge is about 0.5 m. If it is decided to equip the pipe passage through the roof lower along the slope, then the chimney must have a height equal to the height of the ridge. In the event that it is necessary to bring the pipe low down the ramp, the height is calculated according to the scheme shown in the photo.

After determining the height and location of the pipe, you can begin direct work on the preparation of the site. To do this, cut a hole in the roof corresponding to the size of the pipe + 3-4cm. Additional clearance is simply necessary for the arrangement of the flange and the laying of material that prevents fire.

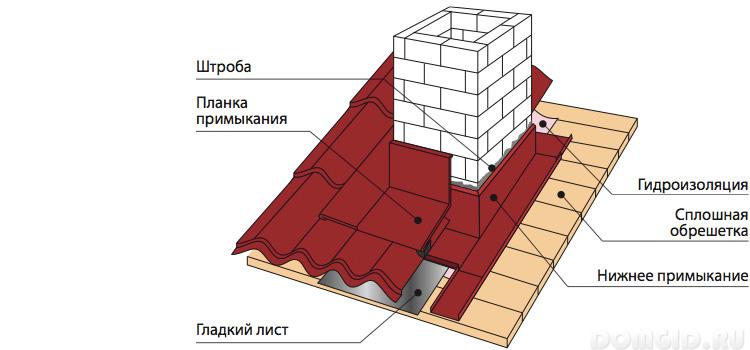

The flange is made of any metal sheet, about 2 mm thick. The hole cut in the metal is reinforced with welded stiffeners. When installing the flange, you must not forget that basalt cardboard is laid on it, which serves to prevent too much heating and heat transfer from the pipe to the roof crate.

After installing the flange, the gaps between the pipe and the roof (the same three to four centimeters) are laid with any non-combustible material. Then it is necessary to carry out work on sealing the joints of the chimney with the roof.

Sealing the roof at the chimney outlet

To seal the adjoining of the roof to the square chimney, special aprons are used, the material for which is roofing sheet, lead or aluminum sheets with an adhesive base.

The apron is laid so that it snugly fits the pipe itself. The upper part should be located on the slope of the roof, and the lower part should be placed under the roofing material. That is, the tin strips for the apron should be covered with roofing sheets that are above and around the chimney.

The adjoining places of the apron to the pipe are reliably sealed, eliminating the ingress of moisture under the apron. For this, they use an aluminum tape with an adhesive surface. It is glued so that one part captures the roof, and the other closely adjoins the pipe.

For reliability, the upper part of the strip on the pipe is fixed with a metal profile strip and fixed with heat-resistant dowels. After fastening, it is necessary to walk with a roofing sealant at all joints and carefully process the fit points.

Features of the installation of a round chimney

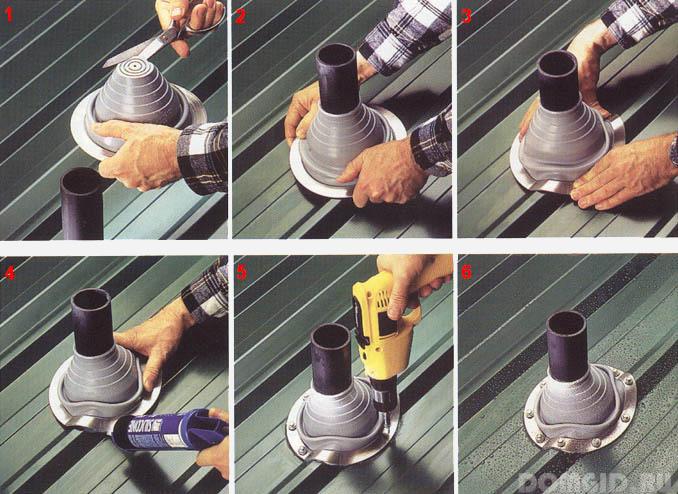

The passage of the chimney through the roof of a round shape is much easier to equip than a square one. Most often, they are purchased ready-made and use factory roofing, equipped with all the necessary components.

One of the most common options is an aluminum flange, which comes with a rubber or silicone corrugation. Manufacturers produce roofing units of different sizes, so choosing the right one for yourself (in diameter) will not be difficult.

If the angle of the roof is maintained at a normal degree, and it itself is made of metal, then the installation of roofing penetration is very simple.

In the corrugation, the upper part is cut off and the penetration is pulled to the chimney pipe. The flange is carefully lubricated with sealant from below and attached to the roof surface. After which it must be screwed to it with self-tapping screws that come with the kit. To the roof, the material for which another type of coating serves, the flange is fastened with dowels or longer self-tapping screws are used, which can be reached directly to the crate.

For roofs in which the angle of inclination is sharper, their own penetration options are provided. You can also purchase kits with detachable corrugation, which are needed if the pipe is too high to pull on the finished structure. Especially for such cases, clamps are included in the kit, with which it is extremely simple to fix the corrugation around the pipe.

Of course, the production of ready-made options for roofing penetrations greatly simplifies the process of sealing the joints of abutment and reduces the time by several times. Moreover, there are a lot of types of this design and it is possible to purchase a penetration under absolutely any pipe and not worry that moisture will get inside the roof.