Search

Login

We choose Knauf insulation, what it is, types, how to choose the right

It is difficult to find a person who has never done repairs in his home, even more difficult - someone who, when performing it, would not have encountered building materials produced by the well-known manufacturer from Germany, Knauf. This industrial group produces a wide variety of products, including modern thermal insulation materials for various purposes. To consider all their advantages and features, it makes sense in more detail - when choosing a heater for walls, floor or roof, the consumer in most cases has to make a choice in favor of Knauf insulation, and to obtain an excellent result, it will be necessary to find the most suitable heat-insulating material in a wide variety.

Content:

- Varieties of insulation Knauf

- Knauf insulation - technical specifications for fiberglass materials

- Positive traits

- Area of \u200b\u200buse video

- Basalt wool video

- Knauf polystyrene, features and benefits

Varieties of insulation Knauf

All heat-insulating materials produced by the company can be divided into two types:

- materials made on the basis of basalt fibers and fiberglass,

- polystyrene tiled materials, commonly used as foam.

Fiberglass-based materials have been used in construction for quite some time. The technology of their manufacture is the extrusion of molten glass mass, when it is pulled into an endless thread, a material with completely original properties is obtained - glass fragility disappears in it, but elasticity and flexibility appear. From fiberglass yarns, it is easy to make plates and rolled web.

Knauf insulation - technical specifications for fiberglass materials

Thermal conductivity fiberglass material is usually equal to 0.032-0.037 W / mK, this figure is lower than that of the foam, i.e. heat saving it provides better.

The vapor permeability of the glass wool insulation can be compared with the same parameter of natural oak or spruce boards, it is 0.5 mg / mchPa. This is about 10 times higher than the one characterized by polyurethane foam. The use of glass wool as a heater when performing outdoor work is possible precisely due to the high vapor permeability index - it provides free penetration of vapors from the inside of the room, which prevents the appearance of condensate.

The density of the material depends on the form of its release, for roll it is 11 kg / mK, for slab - from 15 to 17 kg / mK.

If we talk about the shortcomings of the material, then we need to remember the most serious - the tendency to moisture absorption. But thanks to new developments of technologists and the introduction of the hydrophobization stage in the production process, the water absorption indicators of the material were significantly reduced, it gradually begins to acquire water-repellent characteristics, i.e. resistance to atmospheric precipitation.

Positive traits

- Due to the light weight of the material, its installation does not lead to increased loads on the foundation of the structure, and good flexibility allows for a tight fit of the insulation layer to the surface of the base.

- The biological and chemical neutrality of the material, the absence of formaldehyde and acrylic components in it, suggest that it is not dangerous for use in residential and industrial construction.

- In addition, its structure prevents the possibility of the development of fungi and pathogens.

- When heated, glass wool does not emit any odors.

- The environmental friendliness of the material is ensured not only by the use of natural raw materials in production, but also by the special technology of its manufacture - ECOSE.

Fiberglass insulation for the roof of Knauf in all respects meets international quality standards, with a minimum specific gravity it provides sufficient thermal insulation characteristics.

The material gets into the sale in a strong sealed plastic packaging - this greatly simplifies the transportation and storage of rolls or plates directly at the construction site.

Area of \u200b\u200buse

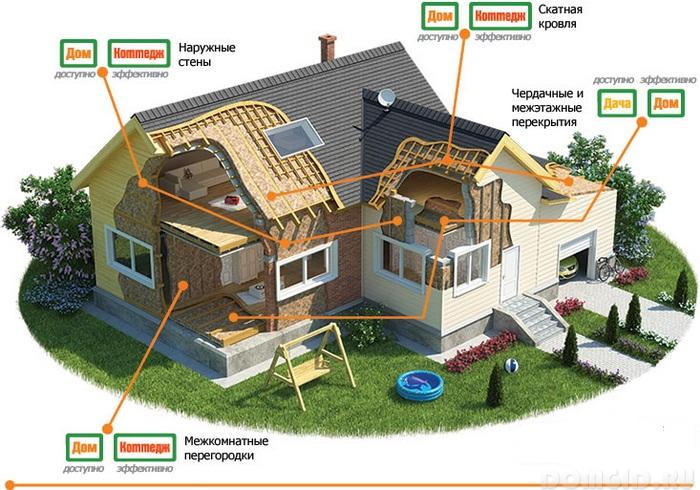

Fiberglass tile materials are actively used by developers in the construction of ventilated facades and prefabricated buildings. Products from Knauff, Heat Plate and Heat Wall can be selected in accordance with the required thickness and thermal conductivity. Plates have a standard size of 1.25x0.61 m, from 5 to 24 pieces can be packaged in their packaging.

Glass fiber roll material Heat roll can be used for thermal insulation:

- facades of any kind,

- pipelines

- floors and floors,

- all kinds of designs with uneven surfaces.

The roll can contain from 6.25 to 10 m of material, the package contains two rolls. The choice is made taking into account the desired coefficient of thermal conductivity.

Knauf-plate insulation with a reduced rate of moisture absorption is designed specifically for warming attic rooms and ceilings. A fiberglass plate called Acoustic partition will save the residents of the house from excessive noise.

The cost of the material depends on its technical characteristics, in addition, the price of Knauf insulation can vary depending on the place of purchase - in wholesale warehouses or large construction markets, it will be slightly lower.

Basalt wool

The second name is stone wool, associated with the raw material from which the material is made. These are: slag mixtures, slags, mining dumps, the manufacturing process consists in their melting and extrusion. The type of basalt insulation can be:

- rolled

- stovetop

- tubular

- it can be found on sale in the form of lamellas glued to aluminum foil.

Different density of the produced material involves its use in different areas of construction:

- knauf roll insulation with a density of 80-100 kg / cubic meter and Knauf Insulation LMF AluR, with a density of 35-90 kg / cubic meter are used for arrangement of air ducts, insulation of baths and saunas, walls,

- knauf Insulation LMF AluR slabs with a density of 150-200 kg / cubic meter are used to insulate the roof and facades, their density can only be compared with the performance of rigid polyurethane foam. Similar in relation to this material and indicators of the coefficient of thermal conductivity of 0.04 - 0.05. It is this low coefficient that makes it possible to classify mineral wool heaters as the most effective heat-insulating materials.

Among the positive qualities should also be remembered about:

- refractory properties

- soundproof,

- extensive scope.

The use of resins of artificial origin as a binder material affects the environmental friendliness of the product. Another positive point is the use of hydrophobization technologies in production, leading to increased moisture resistance.

Chemical and biological neutrality of the material allows its use in housing.

The scope of basalt wool is quite wide, this is insulation:

- flat roofs, walls, facades, pipelines,

- all kinds of engineering and technological objects

- heating systems and air conditioning systems.

The cost of materials from basalt wool is slightly higher than that made from glass wool, the reason for this is a higher density, which is considered a special advantage of the material.

Knauf polystyrene, features and benefits

Foam slabs are made from foamed, using low-temperature liquids, polystyrene raw materials. The baking of the obtained granules is carried out in special forms. Foam material is designed to create thermal insulation systems.

The density of the material can be from 10 to 25 kg / cubic meter. Expanded polystyrene with a lower density is suitable for wall insulation in frame construction, with a higher one - for installation of insulation systems of any nodes in low-rise construction.

Low coefficient of thermal conductivity, corresponding to the same indicator of fiberglass materials - from 0.3 to 0.4, allows you to effectively use the material in different climatic zones. The functionality of the heat insulator is violated at temperatures below -140 or above +80 degrees C.

It is not recommended to use expanded polystyrene for insulation of facades from materials with a higher vapor permeability index - this combination will provoke the formation of condensate and increased humidity inside the building.

Polyfoam is characterized by the lowest coefficient of water absorption among heat-insulating materials, amounting to only 0.8% of the volume during the day.

Statements about the flammability of the material are not entirely true. Firstly, its nature itself contributes to self-extinguishing, and secondly, the ability to maintain combustion significantly reduces the flame retardants used in the manufacture of the material. Different products of the line have a combustibility class from G1 to G3. This is significantly higher when compared with non-combustible mineral wool, however, such a classification does not preclude the use of material in housing construction. It is a positive fact that the maximum time of independent burning is 300 seconds, burning drops are not formed during combustion.

Polyfoam can be attributed to materials that do not have a harmful effect on the human body, because it does not include aldehyde and phenolic compounds. It can be installed indoors without the use of personal protective equipment. Foam is supplied in sealed plastic film bags.

Expanded polystyrene insulation Knauf has found many areas of application in construction. Material, corresponding to its density, is used for insulation of walls and ceilings, attics, facades.

The Knauf insulation intended for the floor has a higher strength, for example, KNAUF Therm FLOOR, can withstand a load of about 15 tons per 1 sq. M. Foams for warming the foundation or base are also distinguished by high technical characteristics.

As for the cost of the most dense polystyrene - insulation for Knauf floor, then it is 2 - 2.5 times higher than the price of ordinary multifunctional insulation boards. It is not difficult to choose the best insulation option for your home - according to the recommended area of \u200b\u200buse, density and cost.