Search

Login

Recommended

We repair the ceramic faucet box with our own hands, how to do it right, master's advice

Is the tap dripping again? Did the ceramics not help and the old problems returned? Let’s then see what can be done. What is a ceramic axle box, we already considered.

Like any mechanism, the axlebox can fail. Consider the typical problems that arise in faucets and faucets that use ceramic taps.

Table of contents

- How to install or remove a crane box

- Gaskets are there or not

- Types of gaskets, methods of replacement and repair video

- Ceramic plates problems with them

How to install or remove a crane box

Crane-boxes with working ceramic pair replaced the valve mechanisms as a more reliable and durable locking element. They fit perfectly with already installed taps and faucets.

It is most reasonable to remove the old axle box and buy a new one in the store by its size. It is worth choosing the diameter and height of the crane axle box, it is also necessary to choose the same seat under the crane lamb.

Before installing a new crane box, the valve seat must be cleaned of scale and mineral deposits. If possible, grind and polish the saddle.

It is necessary to apply a thin layer of waterproof grease to the thread of the axle box, this will simplify the task of removing the product after a while for repair or replacement. To improve the insulation of the axle boxes, one or two layers of sealing tape can also be wound onto the thread.

If possible, screw in the axle box by hand. There is no need to hold a key at this stage. Open water in the riser. Use a wrench to hold the crane box to a condition in which it ceases to allow water to pass through. Further tightening is not recommended, as the lower seal in the valve seat can be damaged.

With such an installation, you will definitely not damage the gasket, but after a while there will be a need to hold on the crane box.

There is nothing complicated in installing a decorative nut and a flywheel. Replacement completed successfully.

Gaskets are there or not

In ceramic axle boxes, as in valve taps, a gasket system is used. It is modified, but still present. More than 90% of problems with leaking ceramic faucet-boxes are caused by the wear of these gaskets.

To remove the crane box and replace or restore the seal is not difficult. Repairing the axle box is easier than it might seem at first glance.

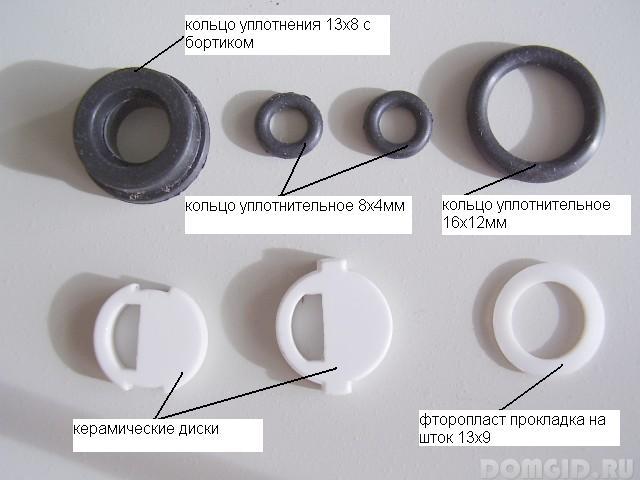

Sealing of the locking element is carried out by two gaskets. The first seals the crane box in the mixer seat. The second presses the upper rotary ceramic plate to the lower plate.

Types of gaskets, methods of replacement and repair

The gasket in the seat of the crane provides a secure fit and sealing of the axle box. Under water pressure, it can sit down or simply wear out over time, which leads to a leak. It should be noted that the valve seat must also be free of cracks and large sinks, otherwise the gasket will not be able to completely seal the connection. In some models, the axle box for fixing the gasket uses a metal ring spring. Over time, it rusts and breaks with all the consequences.

To solve this problem, the product should be selected with a non-metallic element, for example, using plastic rings.

If a problem occurs, replace the gasket at this point. In this case, the crane-axle box does not have to be disassembled, it is only enough to unscrew it from the valve seat. For quick repairs, you can unscrew the axle box, apply a thin layer of silicone to the gasket. When the silicone dries, screw the tap into the axle box in place, the extra height of the gasket can also close the small sinks and scuffs of the valve seat. It is not recommended to apply a layer of silicone directly to the valve seat, since the valve may fail.

The second gasket, made of fluoroplastic, polypropylene or other material similar in its properties, is designed to improve the pressing of the upper ceramic rotary plate to the bottom. This gasket experiences maximum loads during the operation of the crane, which leads to its failure. As a result, it does not sufficiently compress the rotary plate, a gap is formed in the ceramic pair, through which water begins to flow.

Depending on the manufacturer of the crane box, the thickness of this gasket is 0.5-1mm. To replace it, it is necessary to disassemble the axle box and inspect the gasket for damage.

One way to quickly repair is to increase the height of the rotary ceramic plate. Glue 2 balls of electrical tape on the upper ceramic plate. This will be enough for a good hold of the ceramic pair.

Ceramic plates problems with them

In some cases, a problem may arise with the locking element itself with ceramic plates. The distance between the plates is very small and intermolecular interaction arises between them. If a solid particle gets between the plates, this will lead to depressurization of the crane axle box and, as a result, its leakage.

In this case, it is enough to disassemble the crane box, clean the ceramic plates and assemble it, after having greased the plates with a waterproof grease with high viscosity. Manufacturers do not have specific recommendations on the use of certain lubricants, so you can use the one that is available at hand.

When repairing a tug-box, it should be noted that the plates are rubbed on one side, they cannot be turned over or turned around, this will only aggravate the situation, and instead of a repaired crane-box, you will have to sort it out again or buy a new one.

Scuffing and chipping may also form on the surface of the plates. In such cases, to fix the problem, you need to buy a repair kit and replace the plates themselves.

In the budget version, without replacing the ceramic pair, you can try to grind it. The easiest way is to rub the ceramic pair with a stylus from a soft pencil and rub them. Or you can take a more professional approach. To do this, you need a powder of silicon carbide or aluminum oxide (the material from which ceramic pairs are made) with a grain size of 1200. Such material is available in workshops that specialize in tool sharpening.