Search

Login

Finishing the facade of the house with decorative stone, how to do it correctly, useful tips

Since the house is a capital building, the operation of which is planned for many decades, then constructing it should take care of the reliable protection of wall materials from the influence of natural factors. In addition, a very important point is to give the facade the most attractive appearance. Therefore, during the construction or repair of a house, as a rule, they resort to cladding its exterior walls with various finishing materials. This can be clinker brick, plaster, decorative or natural stone. In modern construction, they often resort to the use of decorative stone, which has a high degree of similarity to natural, but has a more expanded color scheme and a wide variety of shapes that mimic natural textures. The popularity of the material today is very high. Moreover, they use decorative stone in the interior as actively as for exterior decoration. It is ideal for design solutions in the styles of Provence, Gothic and medieval, country.

Content

- The advantages of decorative trim stone video

- How to make a finishing stone

- Finishing materials for the facade - choose the right stone

- Artificial stone for the facade - how is its laying

- Finishing the facade with stone - the order of the work video video

- How to stone a basement of a house

- How to care for a decorative stone

The advantages of decorative trim stone

The material used for cladding facades is different:

- practicality and low cost,

- durability and long service life,

- attractive appearance, a variety of colors and textures,

- relatively light weight, not creating additional loads on the foundation,

- the possibility of facing areas of any size and geometry,

- ease of installation even on unprepared surfaces,

- the ability to create original stylistic solutions, including in combination with other finishing materials.

Among the disadvantages are usually mentioned, the service life is lower than that of natural stone.

How to make a finishing stone

Get decorative stone by industrial manufacturing using a fairly simple technology:

first mix the components, adding natural dyes to them,

then poured into special forms and wait for the mixture to solidify completely.

Depending on the components that make up the stone, the following types are distinguished:

- porcelain tile

- concrete stone

- agglomerate.

Finishing the facade of a house is usually done with products made on the basis of concrete mix. For its preparation use:

- base - gray or white cement,

- filler - expanded clay, sand, perlite,

- plasticizer - gypsum, clay, fiber,

- mineral additives increasing heat resistance,

- dyes.

Used fillers have a significant impact on the formation of qualitative characteristics of the material, for example, the use of expanded clay significantly reduces the weight of the stone and its thermal conductivity.

The manufacture of decorative stone using modern vibrocasting technologies consists in filling with a prepared mixture of gypsum silt silicone molds. The resulting material has the form of a tile, the surface of which is smooth on one side and having the texture of natural stone on the other.

Dyes in production are used exclusively of natural origin, they are not prone to change color under the influence of direct sunlight or excess moisture. The drying process of decorative stone lasts 30 days, after this period the material acquires sufficient strength properties.

The shape of the decorative stone can be divided into:

- imitating brickwork, but in a wide variety of colors,

- imitating natural stone - with outlines of irregular geometric shapes, repeating the texture of cobblestone or marble,

- copying the structure of the slate, with the correct geometry, which greatly simplifies the installation process of the finish.

Finishing materials for the facade - choose the right stone

Since the retail network offers decorative stone of different quality, made on a different basis - gypsum, polymer, concrete, it makes sense to clarify which material should be used to clad the exterior of the walls of the house.

The best material for outdoor work is a stone made on a cement basis. When choosing a suitable sample, you should consider it in good light and make sure:

- that its texture exactly repeats a natural stone,

- that there are no pores on the surface,

- that the stone chips have a uniform color - this indicates that during the manufacture of the dye was added to the molding mixture.

You will also need to inquire about the manufacturer of the material. These data, as well as technical characteristics of the material, in particular, indicators of its strength, water absorption, frost resistance, can be obtained from the sales manager or on the official website of the product manufacturer.

Artificial stone for the facade - how is its laying

The installation of decorative stone can be done in three ways:

- mechanical, when the material is hung on the wall, i.e. creates a system of hinged or ventilated facade,

- wet - fixing is done by gluing,

- combined, involving mechanical fastening to the wall, followed by filling with a solution of the space formed between the finishing layer and the wall.

Finishing with decorative stone, carried out by gluing it according to the same technology that tiles are laid on, a layer of glue is applied to the surface of the material, applied to the surface and leveled on it in accordance with the marking, then fixed. Between the tiles there may be gaps for the joints (from 10 to 25 mm) or it can be laid in a seamless way - at an extremely close distance, followed by sealing the joints with a special mixture.

The creation of a ventilated facade involves the construction of a frame, and the fastening of finishing material on it. Typically, such constructions use heaters and vapor-permeable membranes, which leads to the creation of a high-quality heat shield that increases the performance of heat-saving characteristics of the walls.

Finishing the facade with stone - the order of the work

First of all, it is required to decide whether the cladding will be performed on the entire surface of the facade or only the base of the structure will be trimmed, and the rest of the area will be sheathed with siding or plastered.

If a decorative facade stone will be used on the entire surface of the wall, it is advisable to choose a plate of different shades and textures for decoration.

It is possible to finish with stone decoration concrete, brick or cinder block walls or made by the method of fixed formwork. Special preparation of such surfaces is not required - it will be enough to level them. To do this, remove all protruding sections of the plaster, and fill the existing depressions with mortar.

The preparation of wooden buildings is more complicated:

- in wood processing with antiseptic agents,

- sheltering it with a layer of vapor barrier material,

- installation of metal mesh,

- plastering walls,

- primer application.

It should be clarified that all these operations will also need to be performed when facing clay, plastic, asbestos-cement, glass surfaces.

Then you can proceed with the installation of artificial stone.

To carry out the work, you should choose sunny warm days, the air should have a temperature above +5 C and up to +25 C. In order to avoid mistakes and simplify installation, it is recommended to lay out the plates on the site, make a drawing from them, and then transfer it in the appropriate sequence.

Prepare glue for the boards in accordance with the instructions, apply it in small portions on the pasted wall and on the tile itself. You can fix the stone to the wall using a soft rubber mallet. To obtain a uniform seam between fragments, pegs should be inserted between them. Grouting the joints with a special solution is performed after 3 days after the glue has dried.

At the final stage, experts recommend treating the surface of stone tiles with water-repellent impregnation.

Some useful tips to help you get the job done right:

- facing work can only be started if the stress in the masonry of the wall is less than 0.05 MPa, if it exceeds this indicator, then it will be possible to start facing the cladding no earlier than after 3, or even 6 months;

- finishing can be started if all work that may lead to damage to the facing material has already been completed;

- to increase the adhesion of the materials joined by glue, notches should be made on their surface, also dirt and dust should be removed from the surfaces;

- a mandatory procedure is to apply a primer to the wall - the installation of tiles should be on a hard surface.

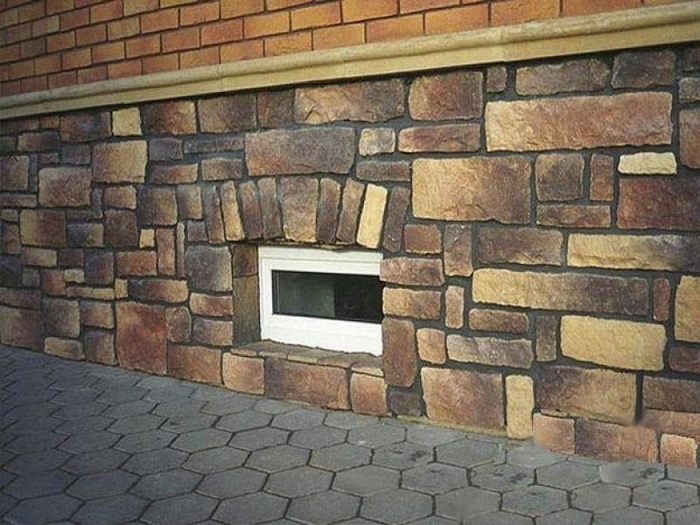

How to stone a basement of a house

To get a quality cladding, you should adhere to the following recommendations:

- if there are remnants of the old cladding on the basement - they should be carefully removed, irregularities on the base should be repaired with fresh plaster,

- if necessary, the base can be insulated, after processing the insulation with a primer, install a reinforcing mesh,

- if warming is not planned - the soil is applied to the surface of the foundation.

Stone laying is carried out according to the same technology as wall decoration, they start work from a visible angle, tiles are laid from bottom to top.

If you need to cut the stone into pieces - you can use a grinder, while using a disk on concrete. For installation, use a frost-resistant adhesive mixture. When laying, it is necessary to achieve the absence of steps, i.e. All plates must be in the same plane. For a more attractive appearance of the seams, they should be deepened a little.

How to care for a decorative stone

In order for the decorative stone to maintain its attractive appearance throughout the entire period of operation and not collapse, a special composition should be applied to it, preventing the penetration of moisture into the material. When designing a structure, a drainage system should be provided that prevents large amounts of wastewater from falling onto the finishing stone - this can provoke the detachment of the finishing layer from the wall. Timely detection and elimination of defects and cracks arising on its surface will help preserve the integrity of the finishing material.