Search

Login

Roof waterproofing from a metal tile, how to choose the right one, how to make it right

The metal tile is a convenient, reliable, lightweight, aesthetically attractive material widely used in the arrangement of the roof. In cottage construction, a metal roof is a kind of de facto standard.

An important role in the indicators of durability and reliability of the roof device will be played by waterproofing. During its installation, specially developed films are used, and the installation itself is performed according to a special technology that provides high-quality hydrobarrier of the roof.

Content

- Roof waterproofing from a metal component of continuous roof operation video

- Materials for waterproofing metal roofing

- Installation of waterproofing under a metal tile

Roof waterproofing from a metal component of continuous roof operation

There are a large number of different roofing materials on the construction market and some developers are confident that with the right choice and high-quality installation of a roofing, it is quite possible to do without waterproofing. A similar opinion exists regarding the metal roof. However, it is not.

A roof made of metal has many gaps through which atmospheric precipitation (snow, rain) penetrates. Over time, under the influence of strong gusts of wind, the weight of the snow cover, the flow of rainwater, the tightness of the metal tile is broken. In addition, the roofing is constantly exposed to water vapor leaving the interior of the facility.

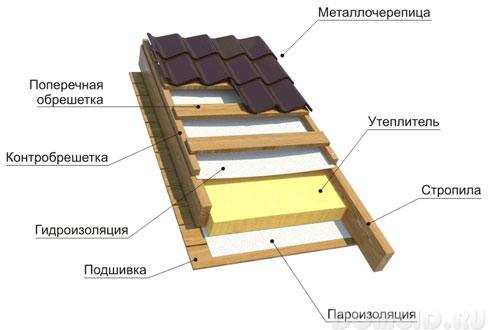

In order to avoid negative consequences when arranging a metal tile roof, a waterproofing layer must be included in the roof pie. This applies equally to cold roofs and insulated.

Thus, waterproofing the roof under a metal tile performs the following tasks:

- prevents the penetration of moisture from the outside;

- prevents the accumulation of condensate on the roofing;

- improves thermal insulation of the entire room.

Metal roofs are durable and reliable. The main thing during their installation is to observe the technology of laying the roofing cake and adhere to the principle of optional tightness.

A small amount of water may flow into small inter-tile gaps, but high-quality waterproofing should divert this water and prevent its accumulation. Due to the small gaps in the coating and microperforation of the hydrobarrier, the supporting wooden crate is ventilated (its service life is extended) and the internal and external air pressure is leveled, which prevents the roof from falling off during strong winds.

Materials for waterproofing metal roofing

quality waterproofing requirements

Parameters of high-quality waterproofing of a metal roof:

- fire resistance;

- high vapor permeability;

- endurance, strength, reliability;

- resistance to temperature fluctuations, exposure to sunlight and other atmospheric influences;

- ability to resist deformation and maintain properties under mechanical loads and changes in natural factors;

- effective removal of moisture from the subroofing space;

- environmental safety for human health (do not contain or emit harmful substances into the atmosphere);

- resistance to pests, mold and rot.

The service life of the waterproofing layer should correspond to the service life of the metal tile, otherwise after some time it will be necessary to repair the roof

If the waterproofing is not replaced in time, then the structural elements of the roof (lathing, insulation, beams and supports) will begin to gradually deform and rot. The indoor climate will deteriorate, and the roof will no longer be reliable.

types and characteristics of waterproofing materials

The range of materials for waterproofing and roofing, and walls, and flooring is very diverse. They differ in thickness, resistance to UV rays, color and other characteristics.

For waterproofing of metal-roofing roofs, a three-layer subroofing film is used, which has a wicker (bearing) reinforcing grating, which is laminated on both sides with a polyethylene film. The film acts as a hydrobarrier and has a vapor transmission capacity.

Bitumen-based waterproofing materials and mastics are not recommended for waterproofing under a metal tile

There are several types of waterproofing film:

- Standard film It has double-circuit ventilation: between waterproofing and roofing, as well as between waterproofing and insulation. Such a film is suitable for waterproofing a roof of a simple design, a cold roof.

- Super diffusion membranes characterized by a high degree of vapor permeability. Therefore, when using them, a single-circuit ventilation between the membrane and the roof covering is sufficient. This waterproofing material is characterized by ease of installation, long service life, endurance and high hydrophobicity. The main disadvantage of superdiffusion film is its high cost.

- Anti-condensation films I have in its composition a special moisture-absorbing material that can hold a large amount of moisture. The surface of the film is rough, and the structure of the material itself is more dense. Additional advantages of the film include its incombustibility, high strength, resistance to UV rays, and low vapor permeability to the disadvantages (condensate is removed by ventilation). Therefore, when using anti-condensation film, it is necessary to organize double-circuit ventilation

As a waterproofing layer for a cold roof, you can use a ruberoid, but at the same time, an air gap must be left between the layer of metal tile and ruberoid

Store the barrier film in places inaccessible to UV rays. To equip a metal-roofing, it is necessary to use a low-combustible type of waterproofing (has a special designation). Such material prevents the spread of fire in a fire and does not form combustible droplets, which can become an additional source of ignition.

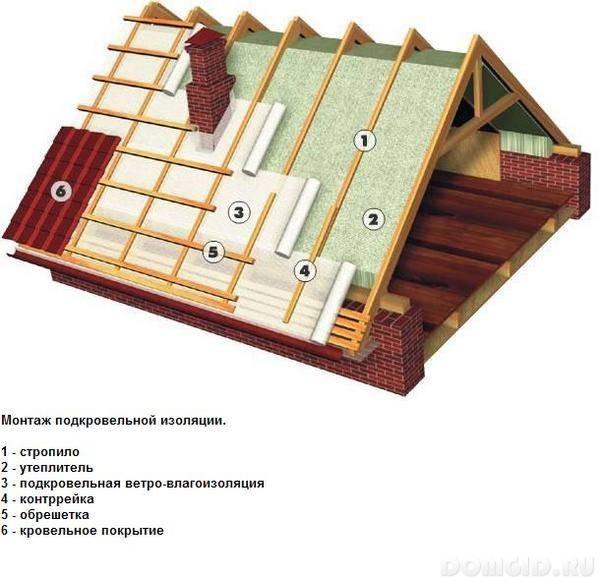

Installation of waterproofing under a metal tile

basic rules for waterproofing a metal roof

The waterproofing of a roof made of metal should be carried out in accordance with the following rules:

- the insulation material must not come into contact with the waterproofing layer (the hydro-barrier film may lose its properties upon contact with the insulation);

- the film is installed on the rafter system;

- the gap between the waterproofing film and the layer of metal should be at least 5 cm;

- the superdiffusion membrane can be laid directly on the rafters, since it does not require a ventilation gap above the heater;

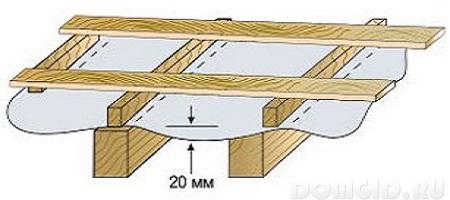

- the film between the lags after installation should sag at least 2 cm (it is impossible to stretch the waterproofing material), it is important to take into account that there is no rupture of the film, which will sit down a little during operation;

- in the ridge zone, it is necessary to organize sufficient ventilation;

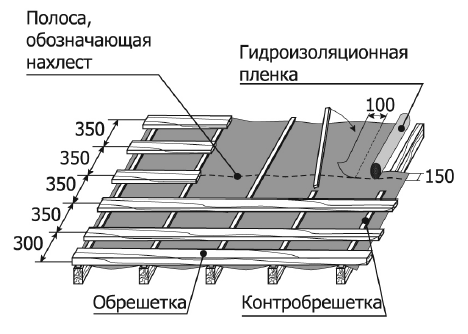

- it is important to control the size of the overlap of the film, which is recommended by the manufacturer (on average, an overlap of about 15 cm; usually the corresponding line is indicated on the film itself);

- the step of the lags on which the film is laid should not exceed 1.2 meters;

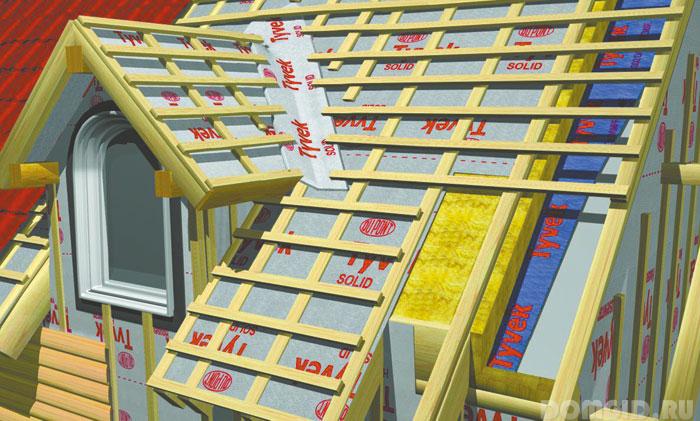

- if there are skylights on the roof, installation of waterproofing should be carried out so that there are no unventilated, blind areas;

- for fastening the waterproofing film, only high-quality, non-corrosive metal staples must be used;

- in places where pipes or ventilation pass, the overlap of the film can be increased or covered with an additional layer of waterproofing material;

- the waterproofing membrane is mounted outwardly with a perforation layer, otherwise moisture will enter under the under-roof space and the film will not be able to fully remove the accumulated condensate.

sequence of waterproofing

When waterproofing a metal roofing, special attention is paid to preparatory work, which includes:

- The construction of the rafter system. The calculation of the rafter structure must be done at the design stage of building a house.

- Install the cornice board and frontal board. This is necessary to give strength and rigidity to the structure.

- Mount the gutter hooks for the gutter system.

Preparatory measures require literacy and professionalism from the contractor, since the quality of their implementation affects not only the roof waterproofing device, but also the stability and reliability of the entire building

To carry out the installation of waterproofing, it is necessary to prepare the following tools and materials:

- scissors for cutting waterproofing film;

- roulette;

- marker;

- long wooden slats;

- hammer;

- construction stapler;

- screwdriver;

- metal staples.

Consider the sequence of installing waterproofing under a metal tile:

- On the rafters, it is necessary to fill the intermediate crate (the height of the slats is not less than 5 cm).

- In parallel, the roll of waterproofing film is rolled out in the horizontal direction. If the angle of the roof is less than 30 degrees, then the overlap between the layers of the film should be at least 25 cm. The film is laid out in the direction from top to bottom.

- Waterproofing is attached to the crate with a construction stapler (temporary fastening, permanent will be done with counter battens);

- In the locations of hatches, dormers, chimneys, waterproofing along the walls of the listed exits must be selected.

- Sets the counter-lattice (wooden slats with a section of 2-5 cm). It is necessary for reliable fastening of the film and ensuring sufficient ventilation of condensate through the film from the room.

- The film must not be laid on the wrong side, the brighter side of the tape should lie facing the metal tile.

- On the ridge of the roof, a clearance of about 5 cm must be provided for ventilation. The edge of the hydrobarrier must reach the installed gutter.

- To fix the film to the protruding building elements of the roof, you can use butyl rubber double-sided tape K-2.

features of waterproofing cold roofs

When arranging a cold inclined roof from a metal tile, an attic space is necessarily provided. The attic must be equipped with a ventilation grill or a window through which moisture vapor will escape.

In this case, roofing material, a vapor barrier film or a superdiffusion membrane can be used as waterproofing.

When installing a highly permeable membrane, ventilation windows and grilles can be left in the attic, this will help to maintain additional heat and protect the attic from rain, snow and street dust. The attic of the house will remain dry, clean. Wasps, birds and insects cannot penetrate into it, and the window can be glazed.

Waterproofing of metal roofing is an important aspect in the construction of a house, which should not be neglected. High-quality and competent roof waterproofing will improve the thermal insulation of the room and extend the life of the roof.