Search

Login

Recommended

How to make a fence made of fiberglass concrete on a personal plot with your own hands

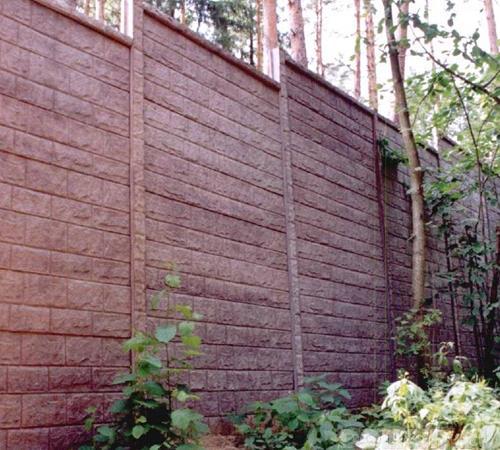

Previously unknown fiberglass concrete, used on a variety of construction sites as a material for the manufacture of various architectural elements of buildings and architectural structures (for example, for facade decoration), began to be in great demand in the era of the development of innovative technologies. Moreover, experienced builders are sure that this is an excellent material for the manufacture of fences. If you plan to install a fiberglass concrete fence on your homestead, but are not sure of your financial capabilities, which forces you to refuse to order a fence in a construction company, this article will come in handy, as you will find a detailed description of installation activities in it fiberglass concrete fence.

Content

- Fiberglass concrete. Main advantages video

- Fiberglass Concrete Fence. Necessary materials and tools

- Sequence of work. Foundation construction

- Direct measures for the construction of fiberglass concrete fence

Fiberglass concrete. Main advantages

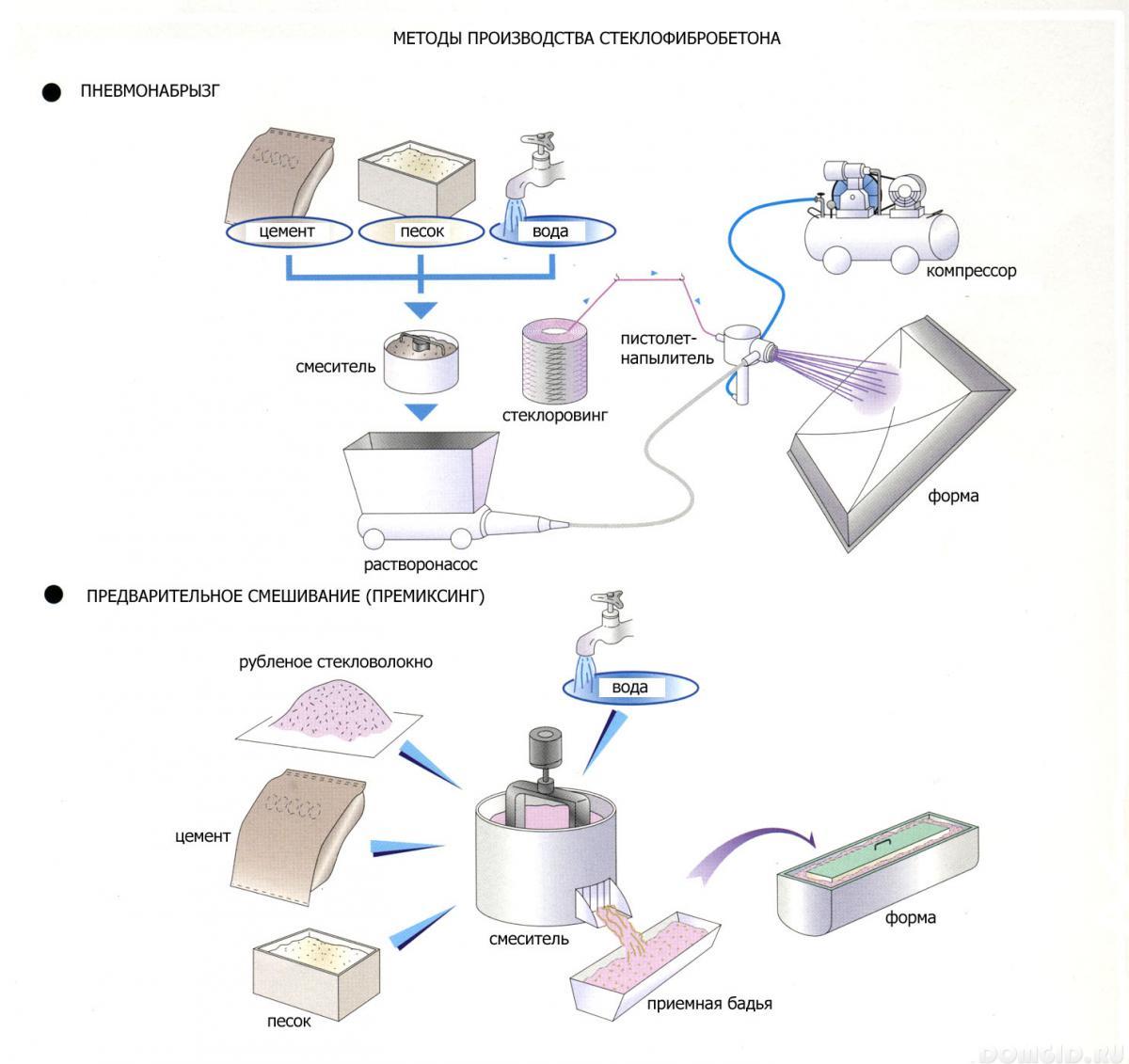

Features of modern material, characterized by increased strength, determine the high cost of the fence, for the manufacture of which fiberglass concrete was chosen. The main difference between newfangled fiberglass concrete and previously known fiber-reinforced concrete is to add to the fine-grained concrete, which acts as a matrix, fiberglass, which is characterized by the function of a reinforcing frame.

Given the above, the use of fiberglass concrete for the manufacture of fences can be considered economically feasible, since it is characterized by the following characteristics, having studied which you will understand that it is in many ways superior to its more common competitors. So, what are the main advantages of the described material?

1. The ability to take the most bizarre forms, which makes it possible to produce exquisite multi-level compositions;

2. The optimal ratio of weight and strength characteristics, which leaves an imprint on the storage and transportation of material, making them the most favorable;

3. The use of fiberglass during the installation of fiberglass concrete, which makes this material perfect from a technological point of view. The structure of the mixture, to which glass fiber was added, suggests a significant increase in strength, resistance to external aggressors and a noticeable decrease in the number of microscopic cracks formed during shrinkage;

4. Improving the heat and sound insulation characteristics of the material in comparison with the usual concrete;

5. High aesthetic characteristics and the ability to recreate any texture, which can also be considered an important aesthetic advantage;

6. Environmental safety, also testifying in favor of fiberglass concrete made from components that are safe for human health.

Fiberglass Concrete Fence. Necessary materials and tools

Even if the happy owner of a personal plot does not pursue the aesthetic pretentiousness of fiberglass concrete decorative elements decorating a fence of this material, it makes sense to think about installing a fiberglass concrete fence yourself.

To build such a fence, the following components will be required:

1. Metal reinforcement, the diameter of which is 10 mm. It is necessary for introduction into the foundation in order to create a shrink base for fiberglass concrete blocks;

2. A cement mortar consisting of two parts of cement and six parts of sand;

3.Construction level;

4. A perforator, which will later be used to form holes of the desired diameter for reinforcing posts in fiberglass concrete blocks;

5. For mixing concrete solution, we also recommend stocking up with a nozzle for a perforator;

6. Rope of necessary length for establishing a horizontally oriented line when laying blocks;

7. Coloring compositions for the final decoration.

Sequence of work. Foundation construction

Before you build a fence of fiberglass concrete, you need to take care of the construction of the foundation. Since the weight of the finished blocks is much lower than the weight of concrete, many developers do not pay due attention to the strength characteristics of the foundation, but this is fundamentally wrong.

The first stage of creating the foundation is marking, the implementation of which must be approached with due scrupulousness.

To do this, preliminarily mark the boundaries of the future foundation, and at the corners drive in stakes, which are subsequently used to strengthen the rope, which serves as a horizontal reference.

Next, calculations are made to determine the number of fence posts that are dug between fiberglass concrete blocks.

After installing the fence line, they dig a trench taking into account its size, the depth of which corresponds to the typical characteristics of the soil on which construction measures will be carried out in the future.

- for continental soils consisting of gravel or coarse sand and which are the most optimal for the installation of the fence, the depth of the trench is 40 cm;

- sedimentary soils, where water sources or groundwater were located in the past, are less suitable for arranging the foundation. If clay masses absorbing moisture prevail in the soil, it is better to abandon the construction of the foundation, since due to excessive absorption of moisture, the destruction of the foundation will be inevitable;

- the sandy foundation, which is a problem for the construction of the foundation, necessitates the deepening of the trench a meter in depth;

- bulk soils, unlike the previous ones, do not present problems for the construction of the foundation.

Direct measures for the construction of fiberglass concrete fence

If you had to deal with the latter, it is enough to dig a trench, the depth of which is 50 cm, and make reinforcement with the help of formwork. In order to build a high-quality fiber-reinforced concrete fence, it is desirable to give preference to the foundation of the tape type, the depth of which is also 50 cm, and the width is not much larger than the fence itself.

The foundation is constructed using gravel, which is laid at the bottom of the trench, along the edges of which formwork is installed from the boards. Next, in the prepared recesses, columns of reinforcement are installed serving as a frame, the diameter of which is 10 mm, and pour it with a specially prepared solution.

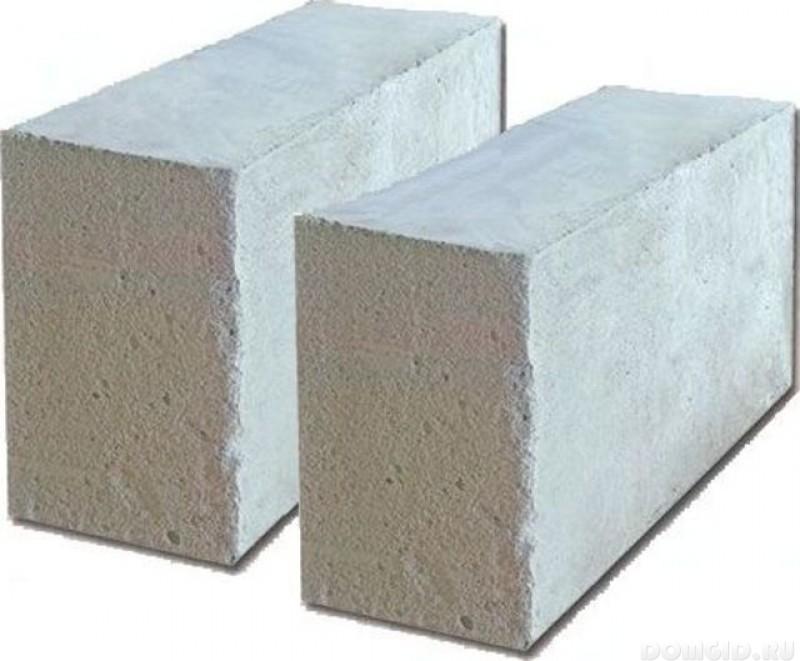

After the foundation is formed, you can proceed to the direct construction of the fence, the basis of which is fiber-reinforced concrete blocks. If you follow the fundamental aspects of the construction of a fiberglass concrete fence and carefully approach the installation of blocks, you can install such a fence without having specialized skills.

1. The essence of the first stage is the installation of hollow core slabs on which concrete mortar will be poured. They are strung on reinforcing posts, having drilled holes in hollow blocks.

2. The first block is completely poured with a solution and a pin of metal with a diameter of 10-20 mm is inserted into its holes, which will be used to connect with the subsequent elements. The length of the pin should be 20-25 cm longer than the length of the block. Installation of the pins is carried out in all blocks of the lower row.

3. Next, a sequential combination of fiberglass concrete blocks is made in the vertical direction until the fence height reaches the intended dimensions. In addition, each block is filled with concrete mortar, if possible with reinforcement.

4.After the pillars are assembled, horizontal fence webs are installed, reinforced with vertical pins that extend beyond the vertical posts and have been described above.

5. The final stage of painting with specialized coloring compounds for concrete surfaces.

Moreover, each owner who installed a fiberglass concrete fence can express his individuality through his design, due to the characteristic feature of the material, which allows to imitate the texture of a wide variety of materials, from marble to wood.