Search

Login

Recommended

Joining wooden parts, methods for joining wooden parts, tools for joining wooden parts

Since ancient times, after the development of tools, man began to build a house of wood. After evolution, man for thousands of years continues to improve the construction of his home. Of course, modern technologies have simplified the construction, provided a wide opportunity for imagination, but the basic knowledge about the properties of wooden structures pass from generation to generation. Consider ways to connect wooden parts.

Content

- Butt connection

- Connection to the invoice

- Half tree connection video

- Length splicing

- Cleat

- Socket-thorn connection

- Using wood to decorate buildings

Consider the methods of joining wooden parts encountered by novice craftsmen. Basically, these are carpentry joints passed down from generation to generation, these skills have been used for more than a century. Before joining the wood, we mean that the wood is already processed and ready for use.

The first basic rule that should be followed when connecting wooden parts is that a thin part is attached to a thicker one.

The most common methods of joining wood, which will be needed in the construction of personal buildings, are of several types.

Butt connection

This is one of the easiest ways to connect (rallying). With this method, it is necessary to fit the surfaces of two connected elements as tightly as possible. Details tightly pressed against each other and fastened with nails or screws.

The method is simple, but to obtain product quality, several conditions must be met:

- the length of the nails should be such that they would go through the entire thickness of the first workpiece with their sharp end into the base of another part to a depth equal to at least ⅓ the length of the nail;

-nails should not be located on one line, and their number should be at least two. That is, one of the nails is displaced from the centerline upwards, and the second, vice versa, downward;

- the thickness of the nails should be such that when they are hammered in the wood a crack does not appear. Preliminary drilling of holes will help to avoid the appearance of cracks in the wood, and the diameter of the drill should be equal to 0.7 of the diameter of the nails;

- in order to obtain better quality of the joint, the surfaces to be bonded should be well lubricated with adhesive, and it is better to use a moisture-resistant adhesive, such as epoxy.

Connection to the invoice

With this method, two parts are superimposed on one another and fastened with nails, screws or bolts. Wood preforms, with this joining method, can be placed in one line or displaced at a certain angle relative to each other. In order for the workpiece joining angle to be rigid, it is necessary to fasten the parts with at least four nails or screws in two rows, two pieces in a row.

If you fasten with only two nails, screws or bolts, then they should be placed diagonally. If the nails will have a through exit through both parts, with subsequent bending of the protruding ends - this method of connection will significantly increase the strength. Connection to the invoice does not require highly skilled craftsmen.

Half tree connection

This method is more complex, it requires already defined skills and a more scrupulous approach to work. For such a connection, in both wooden blanks, the wood is sampled to a depth equal to half their thickness, and a width equal to the width of the parts to be joined.

You can connect parts in half a tree at various angles.

It is important to observe the following rule:

- so that the sampling angle on both parts is equal, and the width of both samples strictly matches the width of the part. Under these conditions, the parts fit snugly against each other, and their edges are placed in the same plane. They fasten the connection with nails, screws or bolts, and glue is still used to strengthen the strength. If necessary, such a connection may be partial. That is, the end of one of the blanks is cut at a certain angle, and in the other part, the corresponding selection is performed. Such a connection is used for angular cohesion. Both spikes (samples) in this case are cut at an angle of 45 degrees, and the joint between them is located diagonally.

Length splicing

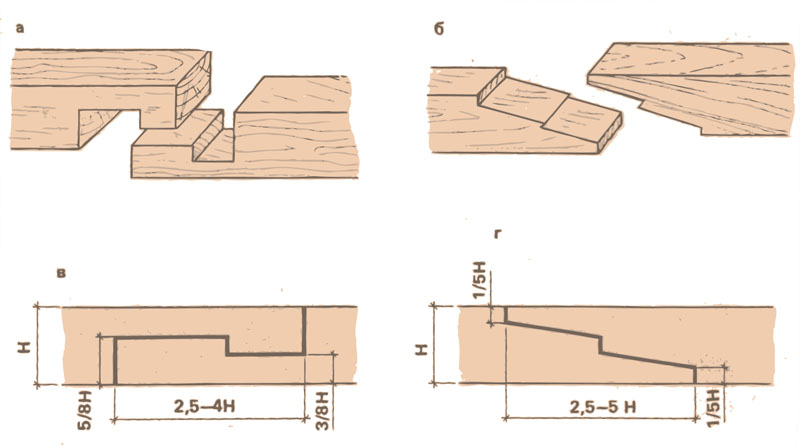

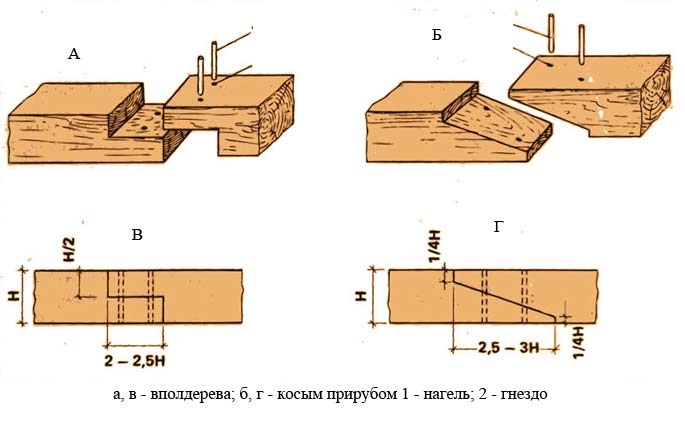

Such splicing of bars and beams along the length has its own characteristics.

For signs for vertical supports, splicing is simple.

But it’s a completely different matter when a beam or a beam in the place of splicing is subject to bending or torsion loads, in this case you can’t do with simple fastening with nails or screws.

Spliced \u200b\u200bparts are cut at an angle (into an oblique overlay) and squeezed with bolts. The number of bolts depends on the applied loads, but there must be at least two.

Sometimes additional pads are installed, for example, metal plates, it is better on both sides, above and below, for strength, you can additionally fasten with wire.

Cleat

Such a compound is used for flooring or for cladding boards. To do this, a spike is made in the face of one board, and a groove in the other.

With this splicing, gaps between the boards are eliminated, and the skin itself takes on a beautiful appearance. Properly processed lumber is supplied to the distribution network, where they can be purchased ready-made.

An example of such materials is a floorboard or wall paneling.

Socket-thorn connection

This is one of the most common compounds of wooden parts.

Such a connection will provide strong, tough and neat rallying.

It goes without saying that it requires certain skills and accuracy in the work of the contractor.

When making this connection, you need to remember that a poor-quality stud connection will not add reliability and will not have a beautiful appearance.

The stud joint consists of a groove hollowed out or drilled in one of the wooden parts, as well as a stud made at the end of another, attached element.

Parts should have the same thickness, but if the thickness is different, then the socket is made in the part that is thicker, and the spike is made in the second, thinner part. The connection is performed on glue with additional fastening with nails and screws. When screwing in a screw, remember that pre-drilling will facilitate this process. The head of the screw is better to hide, and the guide hole should be ⅔ of the diameter of the screw and be 6 mm shorter than its length.

One of the very important conditions is the same humidity of the parts to be connected. If the connected elements have different humidity, then upon drying the spike will decrease in size, which will lead to the destruction of the entire connection. That is why the parts to be connected must have the same humidity close to the operating conditions. For outdoor structures, humidity should be in the range of 30-25%.

Using wood to decorate buildings.

The choice of wood.

In carvings to perform large crafts with large elements are often used coniferous woodas the main one. They are available, and the striped texture can be beaten in the ornaments.

As a background for the consignment note and slotted thread, used fir.

Valuable material is cedar, its soft, with a beautiful texture and a pleasant yellow-pink or light pink core color of wood. Wood is easy to cut, does not crack much during shrinkage and is resistant to decay.

Wood pears used for highly artistic parts of the thread, as it is durable and little warped from weathering.

Poplar, the wood is very soft and light - it is used to make a carved decorative column or background shields for attaching an overlaid thread.

For the manufacture of chains of round rings it is good to use wood apple trees. This wood is used in small crafts, in a laid thread. In this case, the springy properties of the apple tree are used.

Wood is also used. limes. Very light, well planed, perfectly drilled and sanded.

Thread from oak laborious in manufacturing due to its hardness.

But the oak is not afraid of moisture, does not warp. Natural wood products are very beautiful, but they can afford it. To reduce the cost of the product, veneering is used. For example, veneered doors are made, by order of the client, under oak. We get beautiful doors that look similar to natural ones, but at a price much lower.