Search

Login

Recommended

Wooden and concrete floors in the bath, the device of wooden and concrete floors, the nuances and specifics of the construction of floors in the bath.

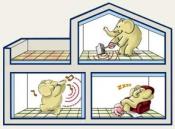

Putting a log house and roofing the bathhouse is only the first, small part of the work to equip and finish this building. Ahead is also the interior decoration of walls and flooring, and the choice of material for them. In principle, there are only two main options for arranging the flooring in the bathhouse, based on the material used, these are wood floors and concrete floors. Each of these options is good in its own way and has its positive aspects. What is the difference and how exactly is this or that gender we will describe below.

Content

- Concrete floor in the bath

- The device of the concrete floor in the bath

- How to make a floor in the bath

- Insulation of the concrete floor in the bath video

- Wooden floor in the bath

- Installation of a wooden floor

- Wooden floor in the steam room

- Wood flooring video

Concrete floor in the bath

Concrete floors in the bath house are equipped both in the washing compartment and in the hot steam room. This is due to the fact that due to the abundance of water flowing freely to the floor, many materials quickly become unusable, and concrete retains its strength. In addition, it is not so difficult to drain the merged water on concrete. Floors poured with concrete mix serve at least 30 years, which justifies the costs of its arrangement.

The device of the concrete floor in the bath

Before starting work on the installation of floors, you should decide on a drainage system through which excess water will leave. Actually, there are two main options for the withdrawal of freely flowing water.

1. Suitable for baths built on light sandy soil. In order to make this drainage system, you need to dig a hole under the washing compartment with a depth of not less than 0.5 m. Fill it with broken brick or pebble (you can use crushed stone). Water will go into this hole and soak into the sand without any problems. The only thing you need to take care of in advance is the vents that must be done in the basement base. Freely circulating air under the floor will eliminate unpleasant odors and excessive moisture.

2. For buildings on heavy clay soils, this option is not suitable. In this case, it is necessary to dig a pit near the walls of the bath and put in it a pipe to drain the water. So that the flowing water does not erode the soil and it does not fill the outlet of the pipe, the walls of the pit should be made of concrete.

How to make a floor in the bath

1. First you need to prepare the foundation for the future gender. To do this, pour a layer of building mixture of gravel, sand and gravel about 15 cm high. All components are taken in equal parts. If there is a drainage pipe for drainage, then a slight bias should be made towards the pit where the water is discharged.

2. Pour the first layer of cement mortar. The mixture should be thick, so it should be prepared at the rate of 1/5, where 1 part is cement, and 5 is sand.

3. After drying of the first layer, thermal insulation lays down. You can choose absolutely any material, from felt to mineral wool.

4. To close a heater a film or roofing material. This is necessary in order to pour on top of the second layer of concrete mix.

5. Before pouring cement on the second layer, a netting net can be put on the covering film and concrete should be distributed on top of it. This home option for reinforcing concrete floors will prevent concrete from cracking during drying and will significantly enhance the strength and durability of the floor.

Wooden floor in the bath

Wood material is warm and possesses powerful energy. For those who don't like dead concrete, wood will be the best option for flooring in a bathhouse. Naturally, not every type of wood is suitable for this important business. You need to choose a lumber that is able to withstand the adverse conditions of high humidity for a long time and not rot. The best options in this case will be larch, which in water acquires reinforced concrete hardness and strength.

Installation of a wooden floor

The device of the floor of the bath from larch boards can be divided into two options:

- Leaking floors

- Waterproof flooring

Leaking floors will generally be quite cheap, and much less installation effort will be required. However, it should be remembered that if you live in the middle lane, this version of the flooring device is not suitable for winter. Such floors are good for giving, when the bathhouse is heated only when gardeners work on the site and they just need to fuss in the beds after a whole day, wash off the labor sweat.

Work on flooring begins with the installation of support racks and lags. For this, a beam is taken with a cross-section of at least 150 * 150 and laid across the width of the room at a distance of 100 110 cm. To prevent bending of the floorboards, the logs are laid on concrete support posts. In principle, wooden racks also make good stands, only they rot very quickly and become moldy, so it is preferable to make them from a more durable material.

Further, boards with a thickness of at least 50 mm are laid on the logs. Sawn timber is laid with gaps of 3-4 cm, which will allow water to freely drain onto the floor.

Wooden floor in the steam room

It is simply unreasonable to arrange leaking floors in the steam room. The bath is appreciated for good steam and the ability to warm up properly, and through the cracks in the boards, a large amount of heat will escape through the gaps. Therefore, in the steam room itself, it is recommended to lay a solid non-leaking floor, equipped with a drain.

Logs and support racks are made in exactly the same way as in the first case. To output wastewater, use a concrete tray, laid on the ground under a slight slope and going to the excavated pit. The soil is covered with a layer of expanded clay.

Next, a draft floor is arranged from an unedged or substandard board, then a layer of a special film that is used for waterproofing and only then a larch floorboard is placed on it.

It is best to lay tongue-and-groove boards, which are connected according to the principle of a thorn groove. Moreover, the groove should be turned inside the bath. By the way, it is better not to nail them, this will allow you to lift the floorboards at any time and, if necessary, dry them. The basic rules of flooring can be seen on our video.

For fastening, you can use whetstones that are pumped up at the joints of the floor with the walls of the steam room. Do not forget about the holes for draining the water. They need to be equipped exactly above the place where the concrete tray for the discharge of wastewater is laid.