Search

Login

Recommended

New in construction, roofing sandwich panels - these are building elements of full readiness

Sandwich panels are successfully used in the construction of industrial premises and residential buildings. To equip the roof, a special roofing type of sandwich panels was developed.

The innovative roofing building material has several advantages, the main of which are: simplicity, installation speed and economic efficiency. It should be borne in mind that the reliability of the structure and its life is largely dependent on compliance with the correct installation technology.

Content

- Roofing sandwich panels: characteristics, design features and composition of building material video

- Types of Roofing Sandwich Panels

- Pros and cons of using sandwich panels in roof shelters

- Features of transportation and storage of roofing sandwich panels

- Mounting technology

- Scope of roofing sandwich panels

Roofing sandwich panels: characteristics, design features and composition of building material

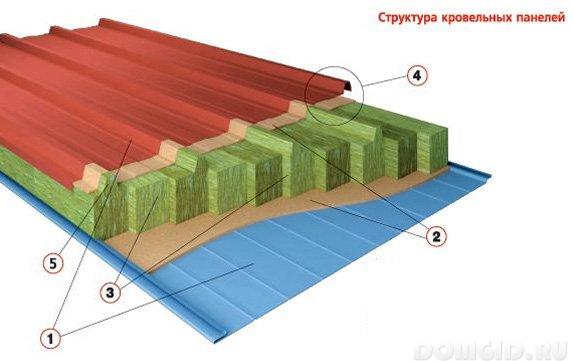

The roofing panel consists of three layers: two layers (upper and lower) metal profile, the third layer (internal filling) insulation.

As a heater polyurethane foam, expanded polystyrene or mineral wool is used. The outer layers of the sandwich panels are made of galvanized metal and are coated with a polymer solution, which creates reliable protection of the roof from corrosion and exposure to aggressive environments (ultraviolet radiation, acid rain). The top side of the roofing sandwich panel usually has protruding trapezoidal ribs.

The structure of the roofing sandwich panel is shown in the figure.

- Polymer coated galvanized steel sheet with multilayer finish

- Synthetic two-component adhesive (polyurethane base)

- Structural insulation lamellas

- Labyrinth-type locking joint

- Trapezoidal lamella of a heater

Roofing panels with internal mineral wool or polyurethane foam insulation have the following characteristics:

- low coefficient of thermal conductivity, which provides good thermal insulation of the house;

- average level of sound insulation;

- ease of construction (the weight of the roofing panel is about 40 kg / sq.m);

- panel thickness is 40-160 mm;

- panel length up to 16000 mm;

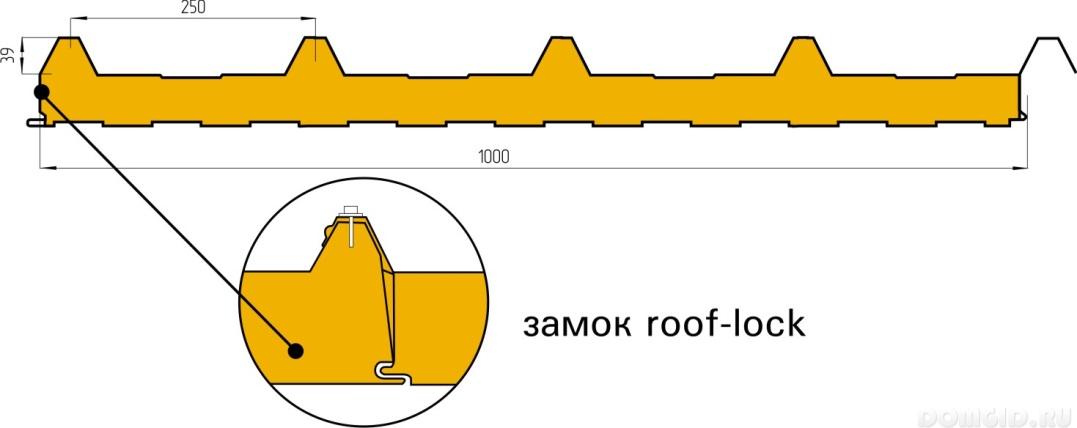

- standard width 1000 mm;

- fire resistance;

- resistance to corrosion;

- aesthetics (panels are available in different colors and you can choose the most suitable option, in harmony with the exterior of the room and the landscape design of the garden).

If necessary, you can order individual sizes of sandwich roofing panels (price per 1 sq. M of such material will be more expensive than the standard size of the panel). For regions with a cold climate, it is possible to improve the thermal insulation of building material by increasing the width of the internal insulation.

Types of Roofing Sandwich Panels

To classify roofing sandwich panels, as well as wall ones, it is possible depending on the filler, the material of the covering sheets and the type of lock connection.

According to the type of heat-insulating material, roofing panels are divided into:

- Mineral wool panels possess high rates of sound insulation and thermal insulation. The filling material is non-combustible, resistant to temperature fluctuations, environmentally friendly. During the term of operation does not shrink. Among the disadvantages can be identified: the severity of the panel, high vapor permeability (there is a risk of delamination of the material).

- Panels with polyurethane foam They have the lowest thermal conductivity and a high level of waterproofing. PUF does not react with alkaline and chemical environments, is flexible and has anti-corrosion protection. The main disadvantage is fire hazard (quickly burns).

- Expanded polystyrene panels environmentally friendly, resistant to deformation under the influence of temperatures, can be installed even in winter. A significant advantage is low weight (twice as lighter as mineral wool designs). Lack of material flammability.

According to the type of facing material, PVC sandwich panels, wood and metal plates are distinguished. For the arrangement of the roof, mainly panels of stainless steel or galvanized steel with various polymer coatings (plastisol, pural, foil, aluminum, polyester) are used.

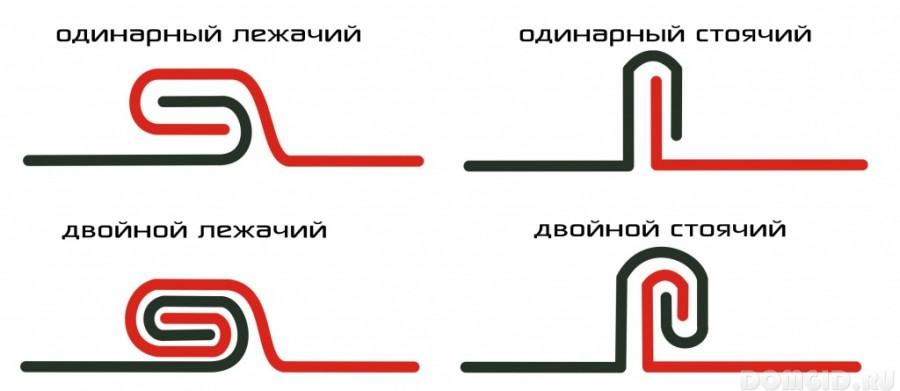

The following locking joints are used to fasten roofing panels:

- Rebate lock

- Castle roof-lock this type of roofing connection practically eliminates leaks that are possible during depressurization of the rebate lock due to thermal expansion of the metal.

Pros and cons of using sandwich panels in roof shelters

The experience of using roof sandwich panels in the construction of prefabricated structures shows the distinctive advantages of their use:

- installation (dismantling) work can be carried out without involving heavy lifting equipment;

- the load on the foundation due to the lightness of the roof structure is not significant, which saves money on the construction of expensive supporting structures;

- tight construction time;

- attractive appearance of the roof;

- durability of a design;

- roof coverings made of sandwich panels with mineral wool are fireproof;

- roofing sandwich panels do not need additional decoration.

Like any building material, sandwich panels have some disadvantages:

- there is a possibility of mechanical damage and slight deformation of the material during improper transportation and storage of panels;

- the roof of the panels needs special sealing, since cracks form when improperly installed or connected to the panels, which will lead to freezing of the room;

- some filling materials are flammable;

- from roofing sandwich panels it is not possible to build roofs of intricate architecture;

- high tightness of the panels makes it necessary to equip a good ventilation system so that there is no greenhouse effect in the room.

Features of transportation and storage of roofing sandwich panels

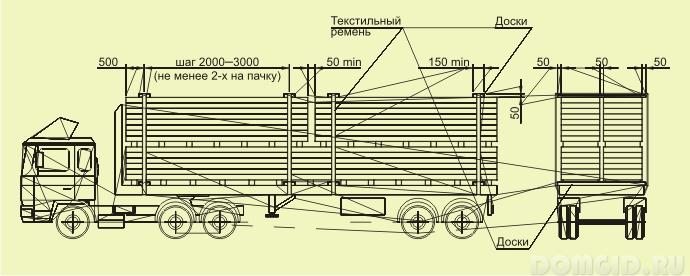

Roofing sandwich panels are rather bulky, the length of some plates can reach 21 meters. Therefore, for their transportation it is necessary to hire specially equipped vehicles.

In order for the material not to be damaged during transportation, the following rules must be observed:

- a solid support must be placed under the ends of the panel that protrude beyond the dimensions of the vehicle;

- the surface level of the trailer must correspond to the surface level of the main body;

- it is advisable to tighten the fastening belts every 100 km;

- width of fixing belts not less than 5 cm;

- transportation speed no more than 70 km / h.

For long-term storage of roofing panels on the street, it is advisable to cover them with a cloth cover (such as a car cover). It is impossible to use synthetic materials after precipitation, the moisture will evaporate for a long time. Periodically, the panels must be ventilated.

In order to prevent dents and other deformations on the sandwich panels during storage, the following rules must be observed:

- Panels cannot be stored at the site where construction work is underway.

- The grounds for the location of the panels must be even.

- Do not store the sandwich panels on the roof.

Mounting technology

preparation for installation and conditions for its implementation

When carrying out installation work and fastening a sandwich panel, you must adhere to the important conditions for high-quality and safe installation:

- work is extremely undesirable to carry out at a wind speed of more than 9 m / s large sizes and low weight of the panels create a good windage;

- during rain, thick fog or snow, installation of roofing sandwich panels is prohibited;

- sealing, joining the joints of panels is best done at an air temperature of more than 4 degrees;

- panels should be trimmed with metal scissors, not a grinder;

- the angle of inclination of the roof with sandwich panels should be at least 5-7 degrees;

- work with roof panels on the roof in soft shoes so as not to damage the polymer coating;

- if the internal insulation is mineral wool, then install the panels in a respirator.

With a roof slope of more than 15 degrees, additional stops are required to prevent the panels from sliding down

Before starting installation, it is necessary to carry out preparatory measures:

- Check the design for compliance with the project, eliminate the differences.

- Check the compliance of the pillars, runs, beams of the project with statistical loads.

- Check the linearity of crossbars, pillars in the walls.

- Make sure that the work in the basement of the room and the end of the waterproofing work are completed.

- Prepare equipment and all necessary tools.

Welding work near a sandwich panel is forbidden to carry out a high risk of damage to the coating of the roofing material

necessary fixtures and equipment

To organize the installation of roofs from sandwich panels, first of all, you need a forklift with special grippers, preferably vacuum ones, but you can also use mechanical ones.

In addition, you must prepare in advance:

- drill, screwdriver;

- the level is needed to control the laying line;

- fabric slings are used to lift roofing plates;

- scissors for metal;

- self-tapping screws;

- selecton sealant;

- insulation;

- sealing washers.

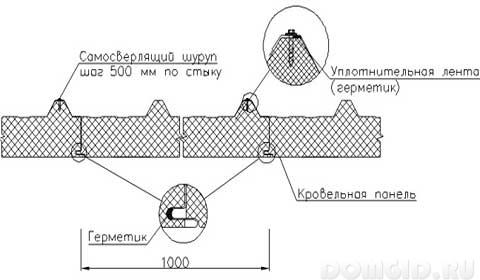

On average, for fastening a blade 2 meters long, 1 meter wide, 4 screws are needed. When calculating the number of self-tapping screws, it should be taken into account that in regions with strong winds the distance between the attachment points should be less.

installation of roofing sandwich panels

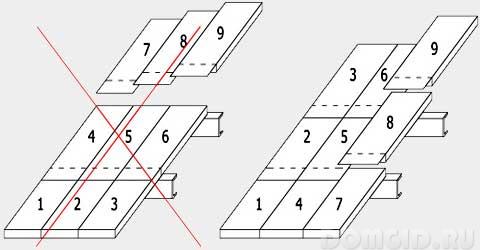

After carrying out preparatory work and studying the documentation (type and size of plates, information about the location of the attachment points, connecting elements), you can proceed with the installation work itself.

The inner protective film from the panels must be removed before installation, and the outer one after completion of work. If necessary, it is necessary to cut the plates. After each cutting, drilling, the skin surface must be carefully cleaned of metal chips.

Laying of plates is made in rows in the direction from the overhang to the ridge. Mount the first panel so that an overhang is formed. The second is covered with sealant, attached to the first plate and to the support. After laying two rows, you can begin to perform a longitudinal interpanel connection. The third and subsequent rows are stacked in the same order.

The size of the overlap with the transverse joint of the roof panels depends on the angle of the roof:

- 30 cm with an inclination angle of 5-10 degrees;

- 20 cm with an inclination angle of 10-20 degrees.

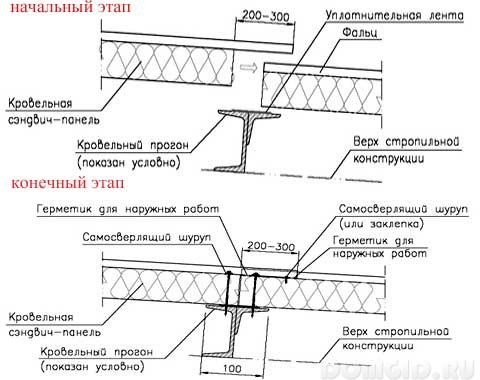

At the upper sandwich panel, the insulation layer and the inner metal sheathing are preliminarily cut by the size of the overlap. A sealant (silicone) is applied to the panel located below. The panels are attached to the roof frame and are interconnected by screws.

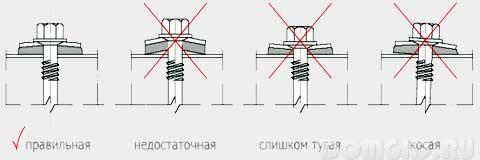

When screwing in, it is advisable to use a gasket, which increases the strength of the fasteners and the tightness of the connection.

Mounting elements must be placed at right angles

The longitudinal connection is performed as follows:

- before laying in the groove of the lock it is necessary to lay a sealant;

- after the roof sheet is fixed on the frame, a mechanical connection is made in the panel locks.

After laying the roofing panels, all joints must be treated with a waterproofing compound. At the end of the installation of the ramps, you can proceed with the installation of the ridge.

Scope of roofing sandwich panels

Roofing sandwich panels have a wide range of uses. They cover the roofs of both industrial buildings, public buildings, and residential buildings.

Roof sandwich panels have gained particular popularity in Europe and America during the construction of so-called frame structures. In recent years, this building material has gained a wide circle of fans among builders and in Russia. It began to be actively used in the construction of shopping centers, the arrangement of covered markets, gyms and pools, office buildings, industrial and warehouse facilities, airports, hangars.

The scope of roofing sandwich panels is expanding every year. Russia has already launched production of this building material. This fact confirms the significant demand, growing popularity, ease of installation and economic feasibility of the use of roofing sandwich panels.